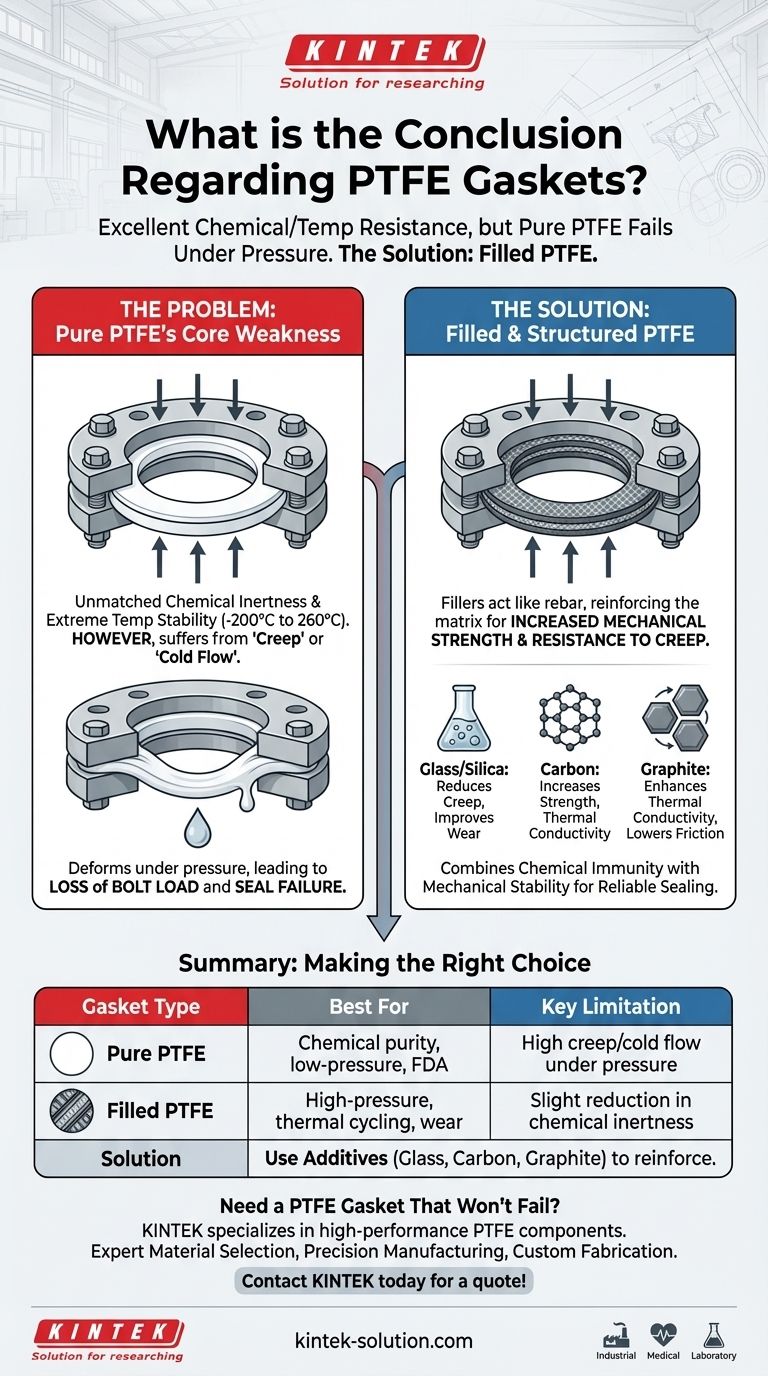

The definitive conclusion is that Polytetrafluoroethylene (PTFE) offers world-class chemical and temperature resistance, making it a premier material for sealing gaskets. However, its effectiveness is entirely dependent on selecting the correct type, as pure, unfilled PTFE possesses a critical mechanical weakness—a tendency to deform under pressure—that can lead to seal failure over time.

While PTFE is an exceptional choice for sealing in chemically aggressive or extreme-temperature environments, its inherent softness means pure PTFE is unsuitable for high-pressure applications. The solution lies in using filled or structured PTFE gaskets that overcome this mechanical flaw.

The Core Strengths of PTFE Gaskets

To understand where PTFE excels, we must look at its inherent material properties. These characteristics make it a default choice for many demanding industries, from chemical processing to food and beverage manufacturing.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It remains stable when exposed to the most aggressive acids, bases, and solvents, ensuring seal integrity and preventing contamination of the process media.

This makes it invaluable for applications where purity is paramount or where gaskets will encounter a wide variety of harsh chemicals.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally wide thermal range, typically from cryogenic temperatures (-200°C / -328°F) up to 260°C (500°F).

This allows a single gasket material to be specified for systems that experience significant temperature swings or operate at sustained hot or cold extremes.

Low-Friction and Non-Stick Surface

The material has one of the lowest coefficients of friction of any solid, making it highly "slippery." This self-lubricating property reduces wear in dynamic or rotating applications.

Its non-stick, non-wetting surface also prevents media from adhering to the gasket, simplifying cleaning and ensuring a high degree of product purity.

Purity and Compliance

Virgin PTFE is non-toxic and can be manufactured to be compliant with FDA and other food-contact regulations. This, combined with its non-contaminating nature, makes it ideal for sanitary applications in the food, beverage, and pharmaceutical industries.

Understanding the Trade-offs: The Problem of "Creep"

The most significant limitation of PTFE is purely mechanical. While chemically robust, pure PTFE is a relatively soft material with poor structural memory.

What is Creep and Cold Flow?

Creep, or cold flow, is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For a gasket, this means the material slowly "flows" or squeezes out from between the flange faces under the constant pressure of the bolts. This happens even at room temperature.

The Impact on Sealing Integrity

As the gasket material creeps, the clamping pressure from the bolts decreases. This loss of bolt load reduces the stress on the gasket surface, eventually compromising the seal and leading to a leak.

This issue is most pronounced in applications with high pressures, significant temperature fluctuations (which cause flange expansion and contraction), or where frequent re-tightening of bolts is not feasible.

The Solution: Filled and Structured PTFE

The industry's solution to creep is not to abandon PTFE, but to enhance it. This is achieved by adding filler materials to the raw PTFE resin.

How Fillers Improve Mechanical Strength

Fillers act like rebar in concrete, creating a reinforced matrix that significantly increases the gasket's rigidity and resistance to creep. These additives dramatically improve the mechanical properties while retaining most of PTFE's desirable chemical and thermal characteristics.

Common Fillers and Their Benefits

Different fillers are used to target specific performance needs. The most common include:

- Glass Microspheres or Silica: Greatly reduce creep and improve wear resistance. This is a very common general-purpose enhancement.

- Carbon: Increases compressive strength and hardness, and improves thermal conductivity.

- Graphite: Enhances thermal conductivity and lowers the coefficient of friction.

By choosing a filled PTFE, you combine the chemical immunity of PTFE with the mechanical stability required for a reliable, long-term seal.

Making the Right Choice for Your Application

Selecting the right gasket is a matter of matching the material's properties to the pressures, temperatures, and media of your system.

- If your primary focus is chemical purity in a low-pressure system: Pure, virgin PTFE is an excellent and cost-effective choice.

- If your application involves high pressure or thermal cycling: A filled PTFE gasket is essential to prevent seal failure due to creep.

- If you need to seal against sensitive or delicate flange materials (like glass or plastic): The conformability of pure PTFE may be an advantage, but pressure must be carefully controlled.

Ultimately, understanding both the strengths and weaknesses of PTFE empowers you to deploy it effectively, ensuring a durable and reliable seal.

Summary Table:

| Gasket Type | Best For | Key Limitation | Solution |

|---|---|---|---|

| Pure PTFE | Chemical purity, low-pressure systems, FDA compliance | High creep/cold flow under pressure | Not suitable for high-pressure applications |

| Filled PTFE | High-pressure systems, thermal cycling, improved wear | Slight reduction in chemical inertness | Additives (glass, carbon, graphite) reinforce against creep |

Need a PTFE Gasket That Won't Fail Under Pressure?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. We understand that the right material choice is critical to your application's success and safety.

We provide:

- Expert Material Selection: Guidance on choosing between pure or filled PTFE based on your specific pressure, temperature, and chemical exposure requirements.

- Precision Manufacturing: Gaskets produced to exact specifications for a reliable, long-lasting seal.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to meet your unique needs.

Ensure your sealing solution is robust and reliable. Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining