At its core, Teflon is a brand name. The material itself is a synthetic fluoropolymer called Polytetrafluoroethylene (PTFE), which was discovered accidentally in 1938 by a chemist named Dr. Roy J. Plunkett. While working at DuPont on a new refrigerant, he discovered an unusual, waxy white powder that proved to be extraordinarily slippery and resistant to heat and corrosion.

Teflon's existence is a lesson in scientific serendipity. Its discovery was a complete accident, but its unique combination of near-frictionless, non-reactive, and heat-resistant properties made it one of the most versatile materials of the 20th century.

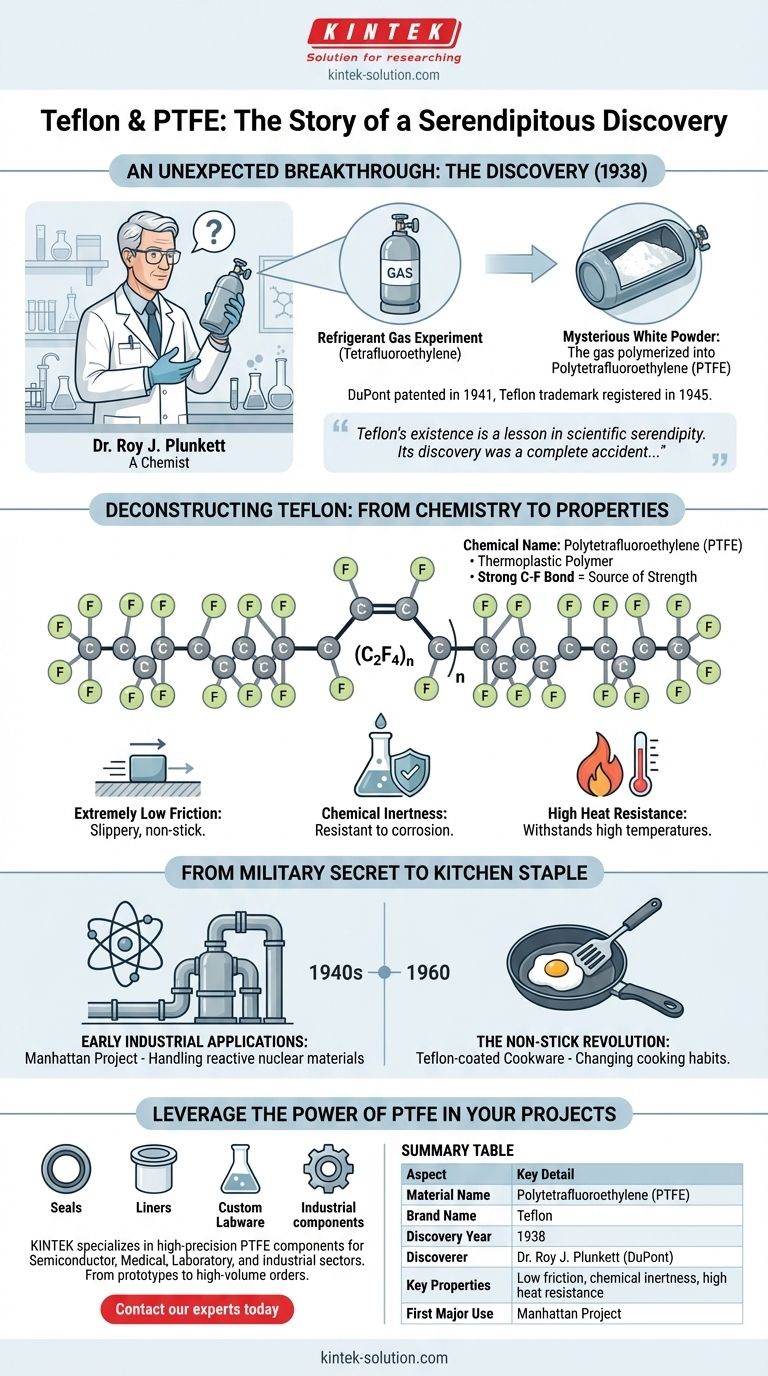

An Unexpected Breakthrough: The Story of Teflon

The origin of Teflon is not one of targeted invention but of a fortunate lab accident that changed industries. Understanding this story reveals why its properties are so unique.

The Experiment Gone "Wrong"

In 1938, Dr. Roy Plunkett was working at DuPont to create a new, non-toxic refrigerant gas. One of his experiments involved a pressurized bottle of tetrafluoroethylene gas.

A Mysterious White Powder

When Plunkett later checked the bottle, he found that the gas was gone, yet the bottle weighed the same as it had when full. Upon cutting it open, he discovered it was coated on the inside with a waxy, incredibly slippery white substance.

From Lab to Market

The gas, tetrafluoroethylene, had polymerized into a new material: polytetrafluoroethylene. DuPont patented this discovery in 1941 and registered the Teflon trademark in 1945.

Deconstructing Teflon: From Chemistry to Properties

Teflon is not just a coating; it is a specific type of plastic with a unique molecular structure that dictates its famous characteristics.

The Chemical Makeup

Teflon's chemical name is Polytetrafluoroethylene (PTFE). It is a thermoplastic polymer, meaning it can be softened by heating and then processed.

Its chemical formula, (C2F4)n, signifies that it is a long chain of repeating carbon and fluorine units.

The Source of Its Strength

The bond between carbon and fluorine atoms is exceptionally strong and stable. This powerful bond is the primary reason for Teflon's signature properties.

Key Defining Properties

This molecular stability gives Teflon three defining characteristics:

- Extremely Low Friction: It is one of the most slippery materials known, which is why things don't stick to it.

- Chemical Inertness: It is highly resistant to corrosion and does not react with most chemicals.

- High Heat Resistance: It can withstand high temperatures without degrading.

From Military Secret to Kitchen Staple

Teflon's journey from a lab curiosity to a household name was not immediate. Its initial applications were highly specialized and critical for industrial and military efforts.

Early Industrial Applications

The first major use for Teflon was in the Manhattan Project during World War II. Its extreme corrosion resistance was essential for handling highly reactive materials used in nuclear development.

The Non-Stick Revolution

It wasn't until 1960 that DuPont introduced the first non-stick cookware coated with Teflon. This application brought the industrial-grade material into kitchens worldwide, forever changing consumer cooking habits.

How to Apply This Understanding

Recognizing Teflon's distinct identity—a specific material (PTFE) with a specific origin story—clarifies its role and value.

- If your primary focus is its scientific origin: Remember that Teflon was a serendipitous discovery in 1938, born from an experiment with refrigerants that went unexpectedly right.

- If your primary focus is its material science: Understand that its chemical structure, polytetrafluoroethylene, is the source of its unique non-stick, non-reactive, and heat-resistant properties.

- If your primary focus is its commercial history: Know that its value was first proven in high-stakes industrial applications before it ever became a household name for non-stick cookware.

Ultimately, Teflon's story shows how an accidental discovery, when properly understood, can transform industries from the top-secret to the everyday.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Material Name | Polytetrafluoroethylene (PTFE) |

| Brand Name | Teflon |

| Discovery Year | 1938 |

| Discoverer | Dr. Roy J. Plunkett (DuPont) |

| Key Properties | Extremely low friction, chemical inertness, high heat resistance |

| First Major Use | Manhattan Project (nuclear development) |

Leverage the Power of PTFE in Your Projects

At KINTEK, we specialize in manufacturing high-precision PTFE components—from seals and liners to custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication ensures you get the exact performance and durability you need, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE solutions can solve your most challenging application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What are the three basic types of PTFE materials? Virgin, Filled, and Expanded PTFE Explained

- Why is PTFE suitable for chemical processing equipment? Achieve Maximum Purity and Safety

- How does PFA compare to FEP in terms of heat resistance and environmental effects? Choose the Right Fluoropolymer

- What are the advantages of expanded PTFE (ePTFE)? Unlock Superior Sealing and Flexibility

- In what medical devices is PTFE commonly used? Essential Components for Safety and Reliability

- What is Polytetrafluoroethylene (PTFE) composed of? The Power of Carbon & Fluorine

- What are the applications of PTFE in various industries? Discover Its Versatile Uses