In essence, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer, a specialized plastic composed of carbon and fluorine atoms. While famous for its use as a non-stick coating on cookware, its primary value is in demanding industrial settings. It serves as a critical material for components like seals, gaskets, bearings, and electrical insulation due to its exceptional resistance to chemicals, heat, and friction.

PTFE's true value lies not in a single trait, but in its rare combination of properties: extreme chemical inertness, a vast operational temperature range, and one of the lowest friction coefficients of any solid. This makes it the default material for many of the world's most demanding industrial environments.

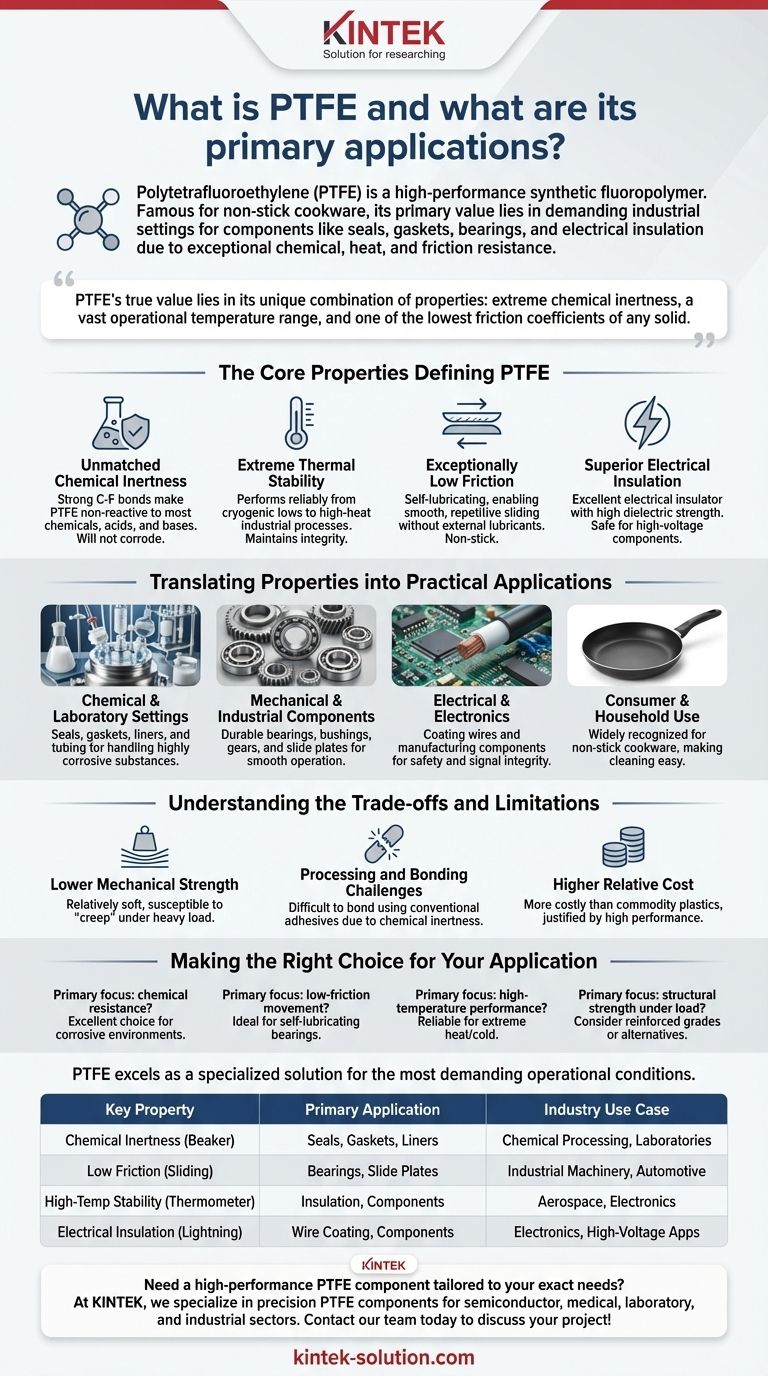

The Core Properties Defining PTFE

To understand its wide range of applications, you must first understand the fundamental characteristics that set PTFE apart from nearly all other polymers. These properties stem directly from its unique molecular structure.

Unmatched Chemical Inertness

The bond between the carbon and fluorine atoms in PTFE is exceptionally strong and stable.

This molecular stability makes the material non-reactive to the vast majority of chemicals, acids, and bases. It simply will not corrode, making it indispensable for chemical processing.

Extreme Thermal Stability

PTFE performs reliably across an unusually broad spectrum of temperatures, from cryogenic lows to high-heat industrial processes.

Where other plastics would become brittle or melt, PTFE maintains its structural integrity and performance characteristics, making it suitable for aerospace, automotive, and heavy industrial use.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This is the scientific principle behind its famous "non-stick" quality.

This property makes it a self-lubricating material, ideal for applications requiring smooth, repetitive sliding action without the need for external lubricants.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength.

It does not conduct electricity, making it a safe and reliable choice for insulating high-voltage wires, cables, and sensitive electronic components.

Translating Properties into Practical Applications

The unique combination of these core properties allows PTFE to solve engineering challenges across a diverse range of industries.

In Chemical and Laboratory Settings

Because of its non-reactivity, PTFE is machined into seals, gaskets, liners, and tubing for equipment that handles highly corrosive substances. You will find it in industrial piping systems and laboratory glassware.

For Mechanical and Industrial Components

Its low-friction nature is perfect for parts that slide against one another. Common applications include durable bearings, bushings, gears, and slide plates that operate smoothly with minimal wear.

In Electrical and Electronics

The material's outstanding insulating properties make it a top choice for coating wires and manufacturing components for the electrical and electronic sectors, ensuring safety and signal integrity.

For Consumer and Household Use

The most widely recognized application is non-stick cookware. The same low-friction surface that benefits industrial bearings makes it easy to cook and clean pans and baking trays.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Being an effective technical advisor means recognizing a material's limitations as clearly as its strengths.

Lower Mechanical Strength

Compared to engineering metals or other high-strength polymers, PTFE is relatively soft. It can be susceptible to "creep," or slow deformation, when placed under a constant, heavy load.

Processing and Bonding Challenges

The same chemical inertness that makes PTFE so valuable also makes it difficult to bond to other materials using conventional adhesives. Its processing and machining require specialized techniques.

Higher Relative Cost

As a high-performance fluoropolymer, PTFE is more costly than common commodity plastics like polyethylene or polypropylene. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting PTFE is a decision driven by a specific, demanding need. Your goal determines if its unique profile is the correct solution.

- If your primary focus is chemical resistance: PTFE is an excellent first choice for seals, gaskets, and linings in corrosive environments where other materials would quickly fail.

- If your primary focus is low-friction movement: It is ideal for self-lubricating bearings, slide plates, and other components requiring smooth, maintenance-free sliding action.

- If your primary focus is high-temperature performance: PTFE maintains its integrity in extreme heat and cold, making it a reliable choice for aerospace, automotive, and industrial processing.

- If your primary focus is structural strength under load: You may need to consider reinforced grades of PTFE or alternative engineering plastics, as standard PTFE is not a high-strength structural material.

Ultimately, PTFE excels not as a general-purpose material, but as a specialized solution for the most demanding operational conditions.

Summary Table:

| Key Property | Primary Application | Industry Use Case |

|---|---|---|

| Chemical Inertness | Seals, Gaskets, Liners | Chemical Processing, Laboratories |

| Low Friction | Bearings, Slide Plates | Industrial Machinery, Automotive |

| High-Temp Stability | Insulation, Components | Aerospace, Electronics |

| Electrical Insulation | Wire Coating, Components | Electronics, High-Voltage Applications |

Need a high-performance PTFE component tailored to your exact needs?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a custom prototype or a high-volume order, our expertise ensures a solution that delivers superior chemical resistance, thermal stability, and low friction.

Contact our team today to discuss your project and experience the KINTEK difference!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is Teflon suitable for food processing applications? Ensure Safety, Hygiene & Efficiency

- What is the sintering process for PTFE billets? A Guide to Achieving Material Integrity

- Why is Teflon considered a relatively expensive plastic? A Guide to Its High-Performance Value

- What makes PTFE suitable for piping and tubing systems? Unlock Superior Chemical Resistance and Durability

- What are some alternative materials to Teflon and their properties? Find the Right High-Performance Polymer for Your Application

- Why is Teflon used in high-performance applications? Unmatched Low Friction & Chemical Resistance

- How is Teflon utilized in the automotive industry? Enhance Vehicle Efficiency and Durability

- What makes PTFE suitable for food manufacturing and packaging? Ensure Safety and Efficiency