In material science, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer. It is renowned for its exceptional properties, most notably its extremely low friction (making it non-stick), its profound chemical inertness, and its stability across a very wide range of temperatures. These characteristics, combined with its excellent electrical insulation, make it one of the most versatile and valuable plastics in modern industry.

While PTFE is most famous for creating non-stick surfaces, its true industrial value comes from a unique triad of properties: near-total chemical resistance, high-temperature tolerance, and superior electrical insulation. The very inertness that provides these strengths, however, also creates its primary practical limitation.

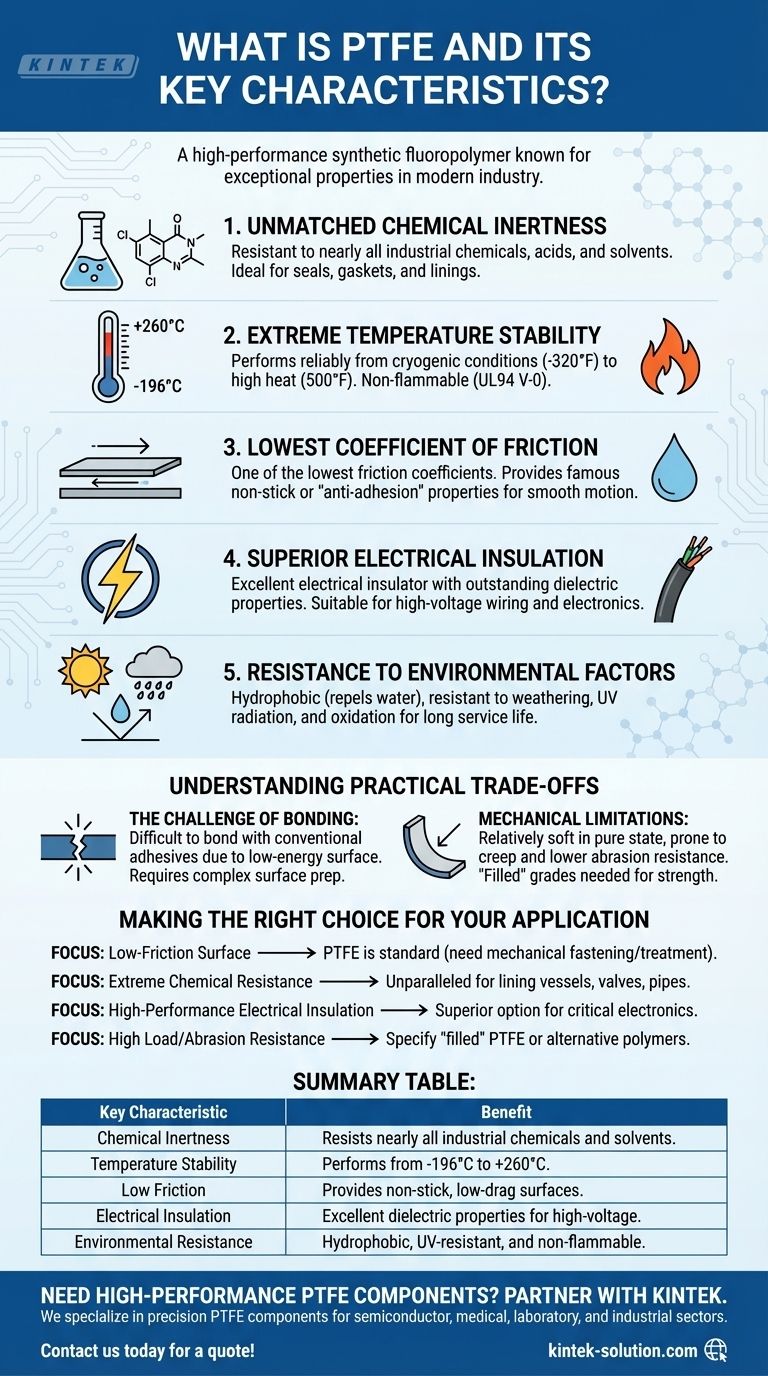

The Core Properties of PTFE Explained

To understand if PTFE is the right material for your application, you must grasp the fundamentals of its key characteristics. Each property makes it uniquely suited for specific, demanding environments where other materials would fail.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and solvents. Its molecular structure is incredibly stable, preventing chemical reactions with substances that come into contact with it.

This makes it an ideal material for seals, gaskets, and linings in pipes and tanks used in the petrochemical, pharmaceutical, and chemical processing industries.

Extreme Temperature Stability

This material performs reliably across a vast temperature spectrum, from cryogenic conditions at -196°C (-320°F) up to continuous service at +260°C (500°F).

PTFE also has a high melting point and is non-flammable, carrying a UL94 V-0 flame rating, which means it resists ignition and does not promote the spread of flames.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, even lower than wet ice on wet ice. This is the source of its famous non-stick or "anti-adhesion" properties.

This characteristic is critical for applications requiring smooth, low-drag surfaces, such as low-friction bearings, slide plates, and non-stick coatings on cookware and industrial equipment.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with outstanding dielectric properties. It does not conduct electricity, making it an ideal choice for insulating high-voltage wires and cables.

Its stability at high temperatures allows it to be used in demanding electronic applications where heat generation is a concern.

Resistance to Environmental Factors

The material is hydrophobic, meaning it repels water and does not absorb moisture. It is also highly resistant to weathering, UV radiation, and oxidation.

This durability ensures a long service life for components exposed to the elements without degradation.

Understanding the Practical Trade-offs

No material is perfect. While PTFE's properties are exceptional, they also introduce specific design and manufacturing challenges that are critical to understand.

The Challenge of Bonding

The same low-energy surface that makes PTFE non-stick also makes it extremely difficult to bond using conventional adhesives.

Attaching PTFE to other materials often requires complex and costly surface preparation, such as chemical etching, to create a bondable surface. This is a crucial consideration in any design.

Mechanical Limitations

In its pure, unfilled state, PTFE is a relatively soft material. It can be prone to creep (deformation under sustained load) and has lower abrasion resistance compared to harder engineering plastics.

For applications requiring higher mechanical strength or wear resistance, "filled" grades of PTFE—which incorporate additives like glass, carbon, or bronze—are often necessary.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is creating a low-friction, non-stick surface: PTFE is the industry standard, but you must engineer a mechanical fastening method or plan for specialized surface treatment to bond it.

- If your primary focus is extreme chemical resistance: Its inertness to nearly all corrosive agents makes PTFE an unparalleled choice for lining vessels, valves, and pipes in harsh environments.

- If your primary focus is high-performance electrical insulation: The combination of excellent dielectric properties and high-temperature tolerance makes it a superior option for critical electronics and wiring.

- If your primary focus is high load or abrasion resistance: You should specify a filled grade of PTFE or consider alternative high-strength polymers to meet your mechanical requirements.

Understanding both its unparalleled strengths and its inherent limitations is the key to leveraging PTFE effectively in your project.

Summary Table:

| Key Characteristic | Benefit |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals and solvents |

| Temperature Stability | Performs from -196°C to +260°C (-320°F to 500°F) |

| Low Friction | Provides non-stick, low-drag surfaces |

| Electrical Insulation | Excellent dielectric properties for high-voltage applications |

| Environmental Resistance | Hydrophobic, UV-resistant, and non-flammable (UL94 V-0) |

Need High-Performance PTFE Components? Partner with KINTEK

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require custom prototypes or high-volume production, our expertise ensures your components meet the exacting demands of your application, leveraging PTFE's unique properties for superior performance and reliability.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments