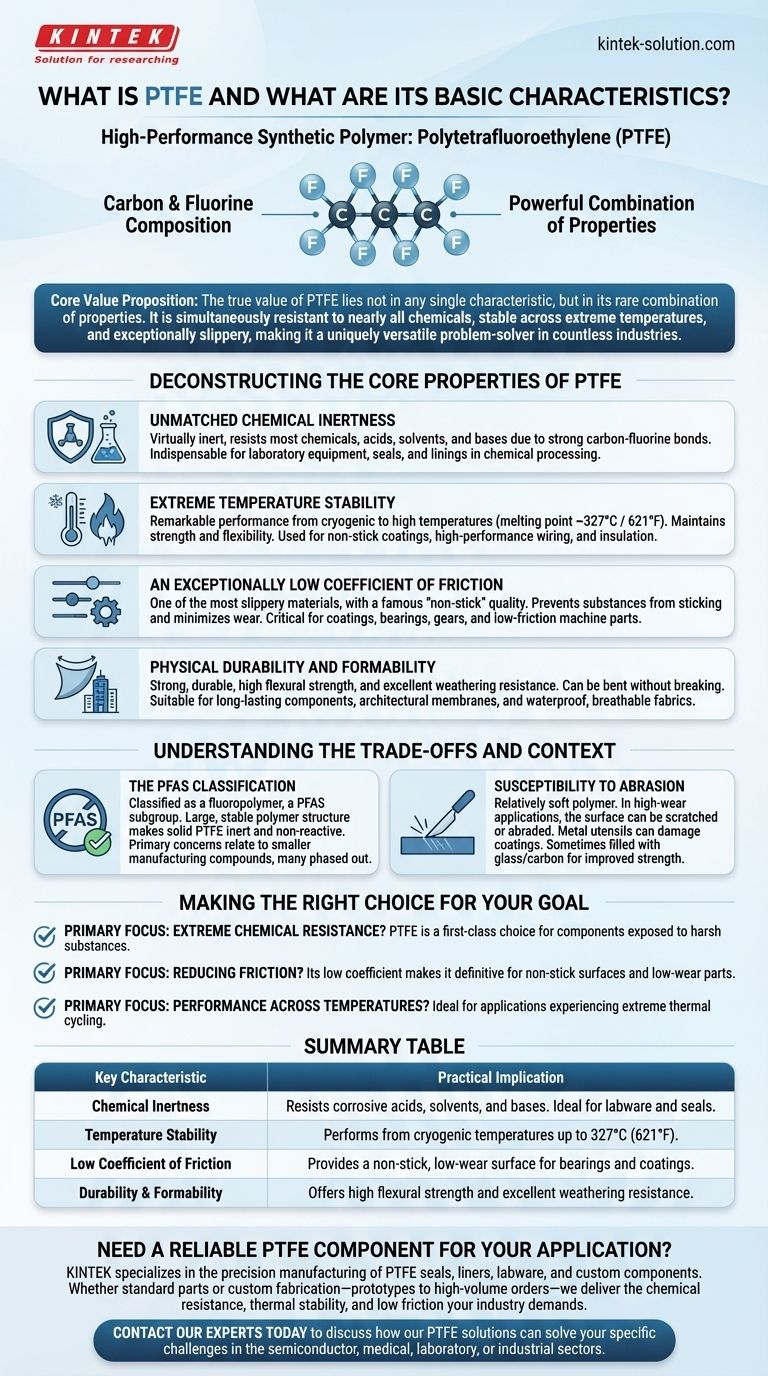

At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic polymer composed of carbon and fluorine, renowned for its unique and powerful combination of properties. It is exceptionally resistant to chemicals, stable across a wide range of temperatures, and possesses one of the lowest coefficients of friction of any known solid, making it famously "non-stick."

The true value of PTFE lies not in any single characteristic, but in its rare combination of properties. It is simultaneously resistant to nearly all chemicals, stable across extreme temperatures, and exceptionally slippery, making it a uniquely versatile problem-solver in countless industries.

Deconstructing the Core Properties of PTFE

To understand why PTFE is so widely used, from aerospace engineering to household cookware, we must examine its fundamental characteristics and their practical implications.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of chemicals. Its strong carbon-fluorine bonds make it highly resistant to corrosive acids, solvents, and bases.

This exceptional resistance makes it an indispensable material for laboratory equipment, seals, and linings used in chemical processing plants where exposure to harsh substances is constant.

Extreme Temperature Stability

The material demonstrates remarkable performance at both high and low temperatures. It has a very high melting point of around 327°C (621°F) and maintains its strength and flexibility even at cryogenic temperatures.

This thermal stability is why it is used for high-temperature applications like non-stick coatings on cookware and as insulation for high-performance wiring.

An Exceptionally Low Coefficient of Friction

PTFE is one of the most slippery materials in existence, a property that defines its most well-known applications. This means other substances do not readily stick to its surface.

This "non-stick" quality is the basis for its use in coating pots and pans, but it is also critical for industrial applications like creating low-friction bearings, gears, and other machine parts where minimizing wear is essential.

Physical Durability and Formability

Despite being a relatively soft material, PTFE is strong, durable, and has high flexural strength, allowing it to be bent or flexed without breaking. It also exhibits excellent weathering resistance.

These properties make it suitable for long-lasting components, from architectural membranes on buildings to waterproof, breathable fabrics in high-performance outdoor clothing.

Understanding the Trade-offs and Context

No material is perfect for every situation. Acknowledging the context and limitations of PTFE is key to using it effectively and responsibly.

The PFAS Classification

PTFE is classified as a fluoropolymer, which is a subgroup of per- and polyfluoroalkyl substances (PFAS). This classification is an important point of context.

However, PTFE's large, stable polymer structure makes it inert and non-reactive in its solid form. The primary environmental and health concerns historically associated with PFAS are linked to different, smaller chemical compounds used during the manufacturing process, many of which have been phased out by industry regulations.

Susceptibility to Abrasion

While durable, PTFE is a relatively soft polymer. In applications requiring high wear resistance against hard or sharp objects, its surface can be scratched or abraded.

This is why metal utensils can damage non-stick cookware coatings and why, in some industrial settings, PTFE may be filled with other materials like glass or carbon to improve its mechanical strength.

Making the Right Choice for Your Goal

Understanding these characteristics allows you to determine if PTFE is the correct solution for a specific engineering or manufacturing challenge.

- If your primary focus is extreme chemical resistance: PTFE is a first-class choice for components exposed to corrosive acids, bases, and solvents where other materials would quickly fail.

- If your primary focus is reducing friction: Its exceptionally low coefficient of friction makes it the definitive material for non-stick surfaces and low-wear mechanical parts.

- If your primary focus is performance across temperatures: PTFE’s stability from cryogenic lows to high heat makes it ideal for applications that experience extreme thermal cycling.

Ultimately, leveraging PTFE effectively begins with appreciating its distinct and powerful set of properties.

Summary Table:

| Key Characteristic | Practical Implication |

|---|---|

| Chemical Inertness | Resists corrosive acids, solvents, and bases. Ideal for labware and seals. |

| Temperature Stability | Performs from cryogenic temperatures up to 327°C (621°F). |

| Low Coefficient of Friction | Provides a non-stick, low-wear surface for bearings and coatings. |

| Durability & Formability | Offers high flexural strength and excellent weathering resistance. |

Need a reliable PTFE component for your application?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you require standard parts or custom fabrication—from prototypes to high-volume orders—we deliver the chemical resistance, thermal stability, and low friction your industry demands.

Contact our experts today to discuss how our PTFE solutions can solve your specific challenges in the semiconductor, medical, laboratory, or industrial sectors.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments