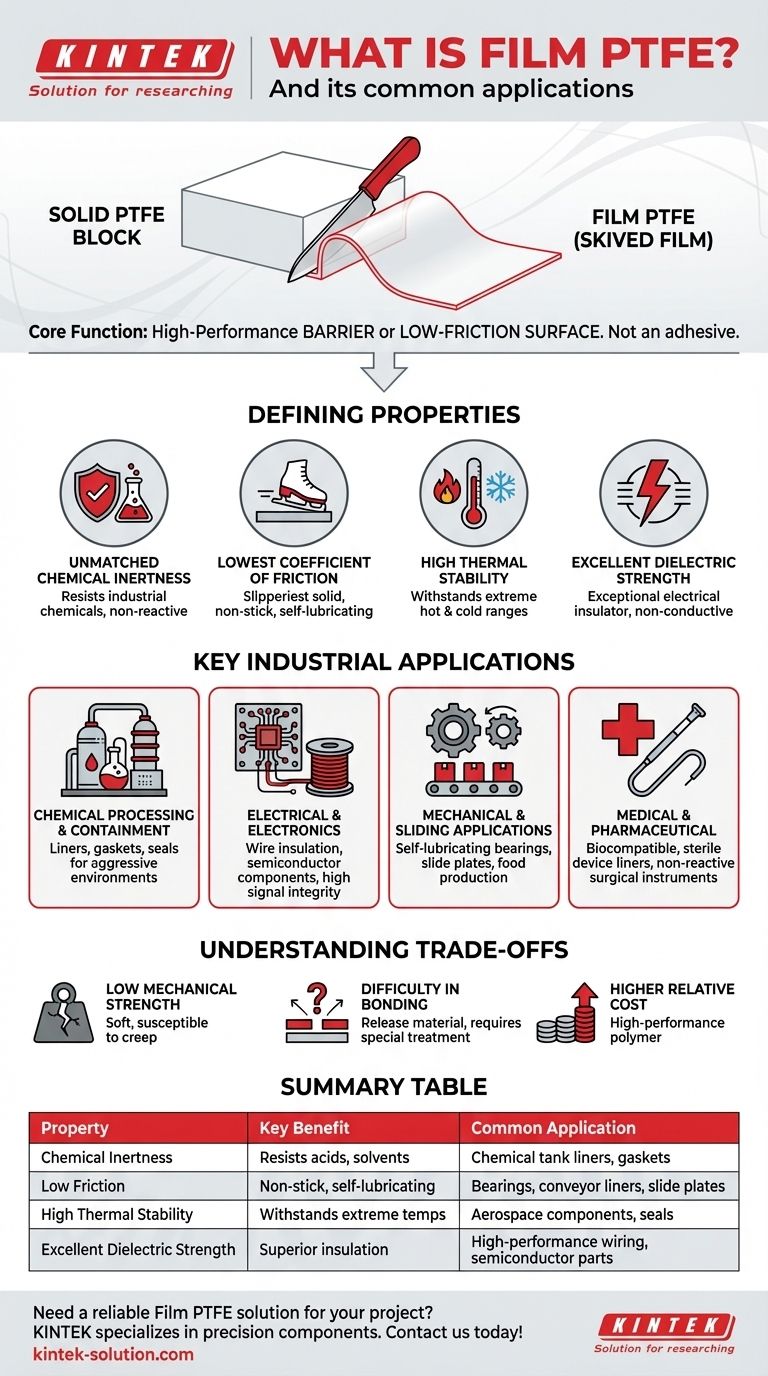

In essence, Film PTFE is a thin, flexible sheet or tape made from Polytetrafluoroethylene, a high-performance fluoropolymer. It is not an adhesive; rather, it is produced by a process called "skiving," where a continuous film is shaved from a solid block of PTFE. This film is valued for its three defining characteristics: an extremely low-friction surface, near-total chemical inertness, and high-temperature resistance.

The core function of Film PTFE is not to bond materials but to serve as a high-performance barrier or low-friction surface. Its value lies in preventing adhesion, chemical reactions, and wear in demanding industrial, medical, and electronic environments.

The Defining Properties of Film PTFE

To understand its applications, you must first understand the fundamental properties of the material itself. These characteristics dictate where and why it is used.

Unmatched Chemical Inertness

Film PTFE is renowned for its ability to resist virtually all industrial chemicals, acids, and solvents. This non-reactive quality makes it an ideal material for protective barriers.

It ensures that the substance being contained or transported does not degrade the film, and the film does not contaminate the substance.

The Lowest Coefficient of Friction

Often cited as one of the slipperiest solid materials known, PTFE has an extremely low coefficient of friction. This is the source of its famous "non-stick" quality.

This property is critical for applications requiring smooth, effortless sliding action with minimal wear and energy loss.

High Thermal Stability

PTFE maintains its integrity across a very wide temperature range. It can withstand extreme cold and high heat without becoming brittle or degrading.

This thermal resistance makes it a reliable choice for components used in high-temperature processes, from aerospace to industrial manufacturing.

Excellent Dielectric Strength

Film PTFE is an exceptional electrical insulator. It does not conduct electricity and can withstand high voltages without breaking down.

This makes it an indispensable material in the electronics and electrical industries for insulating sensitive wires and components.

Key Industrial Applications

The unique combination of these properties makes Film PTFE a critical component in numerous sectors.

Chemical Processing and Containment

Due to its chemical resistance, PTFE film is used to line vessels, tanks, and pipes. It creates a non-corrosive barrier that protects both the equipment and the chemical purity.

It is also fabricated into high-performance gaskets and seals that prevent leaks in aggressive chemical environments.

Electrical and Electronics

As a superior insulator, PTFE film is wrapped around high-performance wires and cables, especially in aerospace and computing where signal integrity and heat resistance are vital.

In semiconductor manufacturing, it's used for components that must withstand harsh chemicals while providing electrical insulation.

Mechanical and Sliding Applications

PTFE film or tape is applied to surfaces to create self-lubricating bearings, bushings, and slide plates. This reduces friction and wear on moving parts, extending equipment life.

It's also used on conveyor rollers and in food production equipment where preventing materials from sticking is essential for efficient operation.

Medical and Pharmaceutical

The biocompatible and inert nature of PTFE makes it a safe material for medical applications. It is used in catheters, surgical instruments, and as a non-reactive liner for equipment.

Its non-stick surface prevents buildup and ensures that medical devices and pharmaceutical processes remain sterile and uncontaminated.

Understanding the Trade-offs

While highly effective, Film PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Low Mechanical Strength

PTFE is a relatively soft material. It can be susceptible to "creep," which is slow deformation under a sustained load, and has poor resistance to high-energy radiation and abrasion.

Difficulty in Bonding

The same non-stick property that makes PTFE valuable also makes it extremely difficult to bond to other surfaces. It is a release material, not an adhesive. Attaching it requires specialized surface treatments like chemical etching.

Higher Relative Cost

As a high-performance polymer, PTFE is more expensive than many common plastics. Its use is typically justified in applications where its unique properties are a strict requirement and lesser materials would fail.

Making the Right Choice for Your Goal

Selecting Film PTFE should be a decision driven by a specific engineering need that other materials cannot satisfy.

- If your primary focus is preventing corrosion: Use PTFE film as a liner or gasket material for its unparalleled chemical resistance.

- If your primary focus is reducing friction: Apply PTFE film or tape to create durable, self-lubricating sliding surfaces for bearings or conveyors.

- If your primary focus is high-performance electrical insulation: PTFE film provides exceptional dielectric strength, especially in high-temperature or demanding environments.

- If your primary focus is purity and non-reactivity: Its inert nature makes it a safe choice for medical devices and food processing equipment.

Ultimately, leveraging Film PTFE is about deploying a superior barrier against friction, chemicals, and heat precisely where other materials fail.

Summary Table:

| Property | Key Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists acids, solvents, and corrosion | Chemical tank liners, gaskets |

| Low Friction | Non-stick, self-lubricating surface | Bearings, conveyor liners, slide plates |

| High Thermal Stability | Withstands extreme temperatures | Aerospace components, high-temperature seals |

| Excellent Dielectric Strength | Superior electrical insulation | High-performance wiring, semiconductor parts |

Need a reliable Film PTFE solution for your project? KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for chemical resistance, low friction, and thermal stability. Contact us today to discuss how our PTFE expertise can enhance your product's performance and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials