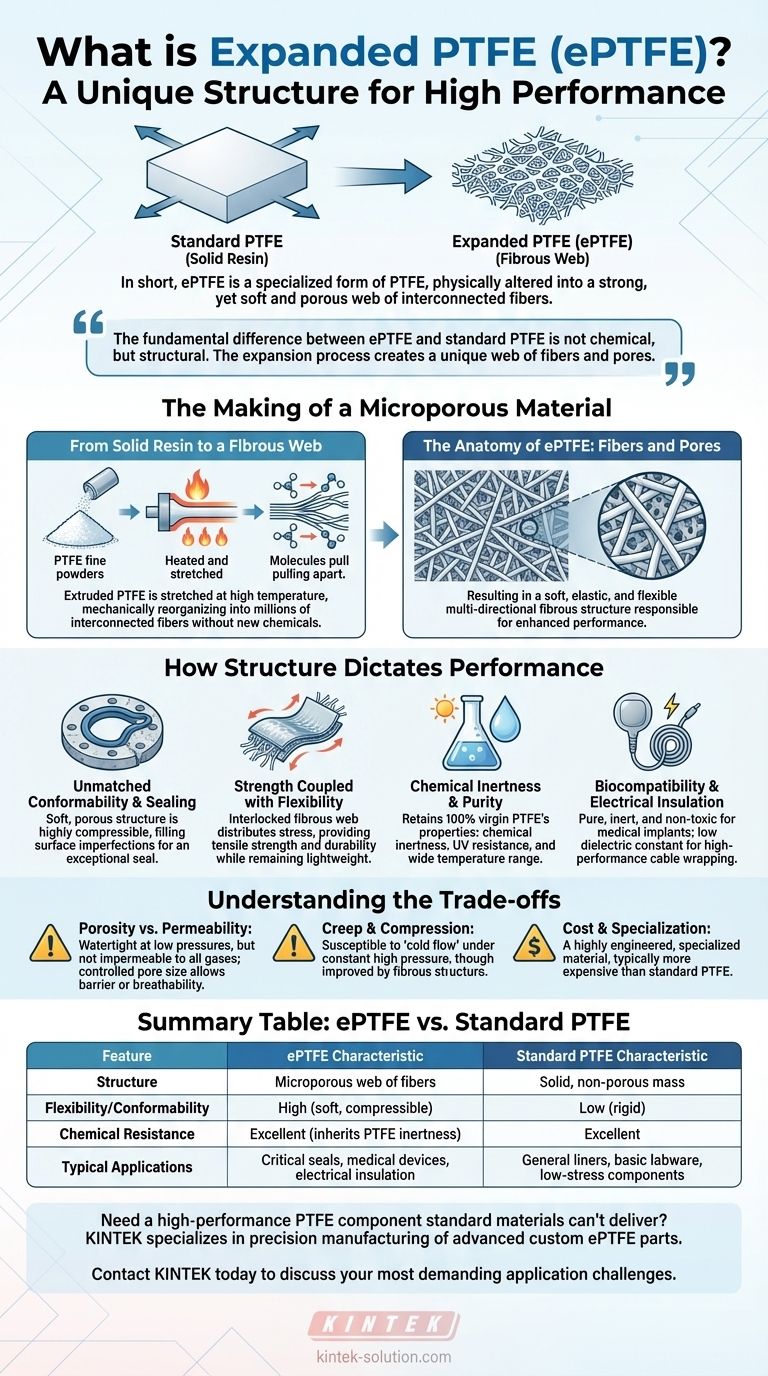

In short, expanded PTFE (ePTFE) is a specialized form of standard Polytetrafluoroethylene (PTFE) that has been physically altered to create a unique material structure. The manufacturing process involves stretching pure PTFE under specific conditions, which transforms the solid material into a strong, yet soft and porous web of interconnected fibers. This microporous and fibrous nature is what gives ePTFE its distinct and highly valuable set of properties.

The fundamental difference between ePTFE and standard PTFE is not chemical, but structural. The expansion process creates a unique web of fibers and pores, transforming a rigid plastic into a soft, strong, and highly conformable material ideal for demanding sealing, medical, and electronic applications.

The Making of a Microporous Material

To understand ePTFE's capabilities, you must first understand how its structure is created. It begins as 100% virgin PTFE but undergoes a radical physical transformation.

From Solid Resin to a Fibrous Web

The process begins by extruding special PTFE fine powders. The crucial step follows: this extruded material is rapidly stretched at a high temperature.

This "expansion" does not add any new chemicals. Instead, it mechanically pulls the PTFE molecules apart, reorganizing them from a solid mass into a network of millions of microscopic, interconnected fibers.

The Anatomy of ePTFE: Fibers and Pores

The resulting material has a multi-directional fibrous structure. Imagine a dense, microscopic web where countless tiny strands are interlocked with one another, creating a matrix filled with tiny pores.

This structure is often described as feeling like a "dense marshmallow"—it is soft, elastic, and flexible. This unique anatomy is directly responsible for the material's enhanced performance characteristics.

How Structure Dictates Performance

The value of ePTFE comes from how its unique fibrous network creates properties that go beyond those of standard, solid PTFE.

Unmatched Conformability and Sealing

The soft, porous structure makes ePTFE highly compressible and conformable. When used as a gasket or sealant, it can easily fill in surface imperfections, even on wide or damaged flanges, creating an exceptionally tight seal.

This adaptability allows it to perform where rigid gaskets would fail, ensuring full resistance against aggressive chemicals even on irregular surfaces.

Strength Coupled with Flexibility

While it is soft, ePTFE is surprisingly strong. The strength comes from the interlocked, multi-directional nature of its fibers.

This fibrous web distributes stress across the material, providing excellent tensile strength and durability while remaining lightweight and flexible. It can withstand extreme temperatures and harsh environments without becoming brittle.

Chemical Inertness and Purity

ePTFE is made from 100% pure, virgin PTFE. It therefore retains the legendary properties of its parent material, including near-total chemical inertness, excellent UV resistance, and a very wide operating temperature range.

The expansion process does not compromise these core chemical attributes, making it safe for the most aggressive services.

Biocompatibility and Electrical Insulation

Because it is pure, inert, and non-toxic, ePTFE exhibits excellent biocompatibility, making it a critical material for medical implants and devices.

Furthermore, the pores within the structure contribute to a very low dielectric constant, making it an excellent electrical insulator used for wrapping high-performance cables.

Understanding the Trade-offs

No material is perfect for every situation. Understanding ePTFE's limitations is key to using it effectively.

Porosity vs. Permeability

The microporous structure makes ePTFE watertight at low pressures, but it is not inherently impermeable to all gases. The size of the pores can be controlled during manufacturing, allowing it to function as either a barrier or a breathable membrane depending on the grade.

Creep and Compression

Like all PTFE materials, ePTFE can be susceptible to "creep," or cold flow, under a constant, high-pressure load over time. While its fibrous structure improves resistance to this compared to standard PTFE, it remains a critical design consideration for high-pressure, static sealing applications.

Cost and Specialization

ePTFE is a highly engineered material produced through a specialized process. This makes it more expensive than standard PTFE or other common sealing materials. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Your final decision should be guided by your primary technical goal. The unique structure of ePTFE makes it a problem-solver for specific, demanding challenges.

- If your primary focus is an aggressive chemical seal: Use ePTFE for its unmatched chemical inertness combined with superior conformability to imperfect surfaces.

- If your primary focus is medical or food-grade applications: Choose ePTFE for its inherent purity, biocompatibility, and non-toxic properties.

- If your primary focus is high-frequency electrical insulation: Select ePTFE for its extremely low dielectric constant and excellent insulating properties.

- If your primary focus is a low-cost, structurally rigid component: A standard, non-expanded polymer is likely a more suitable and cost-effective choice.

Ultimately, understanding that ePTFE's power comes from its fibrous structure is the key to leveraging its exceptional performance in the most demanding environments.

Summary Table:

| Key Feature | ePTFE Characteristic | Standard PTFE Characteristic |

|---|---|---|

| Structure | Microporous web of interconnected fibers | Solid, non-porous mass |

| Flexibility/Conformability | High (soft, compressible, ideal for irregular surfaces) | Low (rigid) |

| Chemical Resistance | Excellent (inherits full PTFE inertness) | Excellent |

| Typical Applications | Critical seals, medical devices, electrical insulation | General liners, basic labware, low-stress components |

Need a high-performance PTFE component that standard materials can't deliver?

At KINTEK, we specialize in precision manufacturing of advanced PTFE components, including custom ePTFE parts. Our expertise in materials science ensures you get the exact properties your application demands—whether it's superior conformability for a critical seal, biocompatibility for a medical device, or exceptional insulation for electronics.

We partner with semiconductor, medical, laboratory, and industrial clients to transform challenging requirements into reliable, high-performance solutions. From initial prototypes to high-volume production, we prioritize precision and quality.

Contact KINTEK today to discuss how our custom ePTFE and PTFE fabrication capabilities can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do high PV grades of PTFE perform in demanding applications? Excel in High-Speed, High-Load Environments

- What makes machined PTFE suitable for industrial applications? Unmatched Performance in Extreme Conditions

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- What makes PTFE butterfly valves special compared to other types? Unmatched Chemical & Thermal Performance

- What are the main advantages of using PTFE heat press sheets? Achieve Flawless, Professional Results

- What are mechanical seals with PTFE sealing rings? High-Performance Seals for Extreme Conditions

- How does PTFE rod function in electrical applications? Unmatched Insulation for Extreme Conditions

- How do PTFE gaskets benefit industrial operations in terms of maintenance? Reduce Downtime and Costs