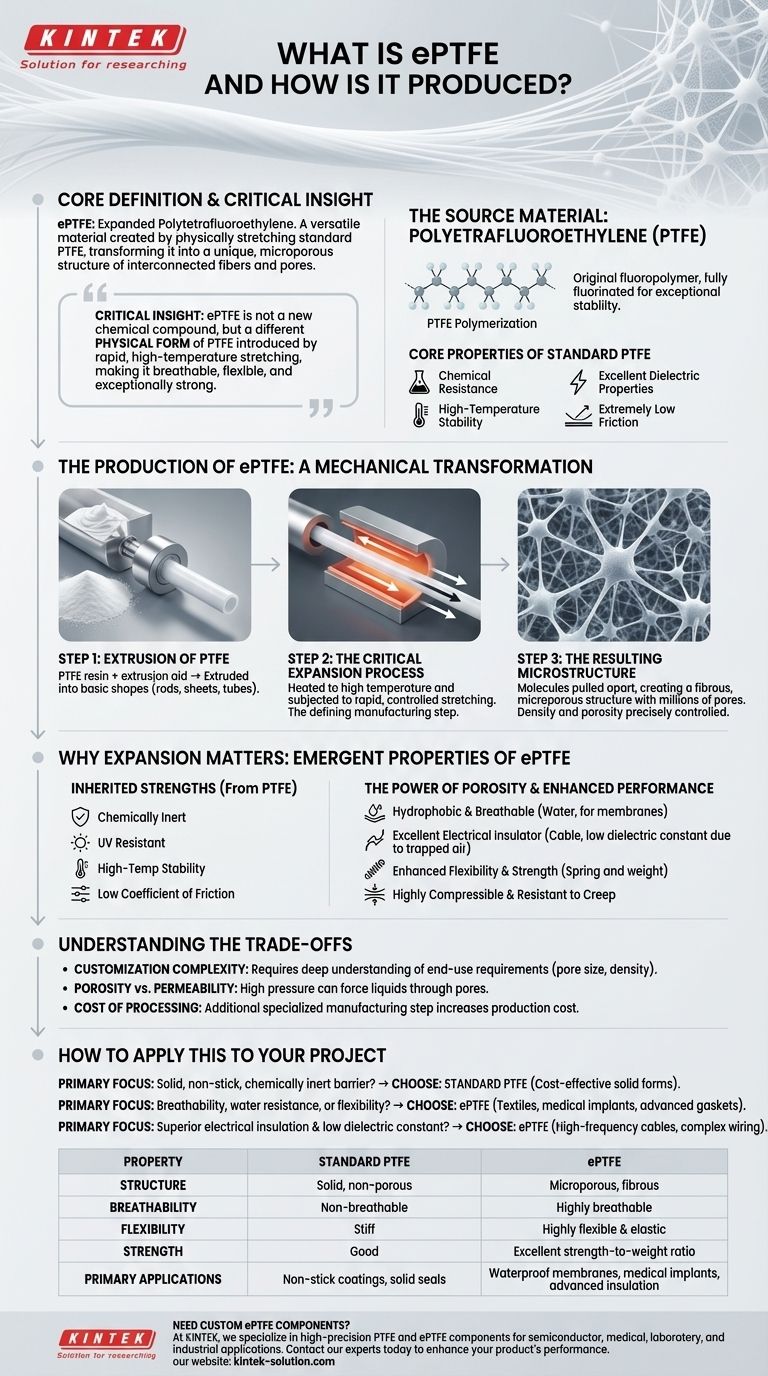

At its core, expanded Polytetrafluoroethylene (ePTFE) is a highly versatile material created by physically stretching standard PTFE. This mechanical process transforms solid PTFE into a unique, microporous structure composed of interconnected fibers and pores, unlocking a new range of properties while retaining the remarkable characteristics of the original polymer.

The critical insight is that ePTFE is not a different chemical compound from PTFE, but rather a different physical form. The manufacturing process of rapid, high-temperature stretching is what introduces a microporous, fibrous structure, making the material breathable, flexible, and exceptionally strong for its weight.

Understanding the Source Material: Polytetrafluoroethylene (PTFE)

What is PTFE?

PTFE is the original fluoropolymer, a synthetic material created through the polymerization of tetrafluoroethene molecules. It is a fully fluorinated polymer, which is the source of its exceptional stability.

Core Properties of Standard PTFE

Before it is expanded, standard PTFE is renowned for a powerful set of baseline characteristics. These include outstanding chemical resistance, high-temperature stability, excellent dielectric (insulating) properties, and an extremely low coefficient of friction, making it one of the most non-stick substances known.

The Production of ePTFE: A Mechanical Transformation

Step 1: Extrusion of PTFE

The process begins with PTFE resin, often in the form of fine powders mixed with a volatile extrusion aid. This paste is then extruded—pushed through a die—to create basic shapes like rods, sheets, or tubes.

Step 2: The Critical Expansion Process

After the initial extrusion, the PTFE material is subjected to a specialized process. It is heated to a high temperature and then stretched very rapidly.

This act of rapid expansion is the key manufacturing step that defines ePTFE.

Step 3: The Resulting Microstructure

The stretching process doesn't just make the material bigger; it fundamentally alters its internal structure. It pulls the PTFE molecules apart, creating a web-like network of solid nodes interconnected by extremely thin, strong microfibers.

The spaces between these fibers create millions of microscopic pores, transforming the solid material into a microporous one. The final density and porosity can be precisely controlled to suit specific applications.

Why Expansion Matters: The Emergent Properties of ePTFE

Inherited Strengths

First, it's crucial to understand that ePTFE retains all the remarkable properties of its parent material. It remains chemically inert, resistant to UV degradation, stable at high temperatures, and possesses a low coefficient of friction.

The Power of Porosity

The new microporous structure introduces powerful new capabilities. The material is now hydrophobic (water-resistant) at low pressures yet breathable, allowing vapor to pass through. This makes it an ideal material for waterproof-breathable membranes.

This structure also makes ePTFE an exceptional electrical insulator, as the pores trap air, resulting in a very low dielectric constant ideal for high-performance cables.

Enhanced Mechanical Performance

The fibrous structure gives ePTFE a unique combination of flexibility, elasticity, and high strength. It is highly compressible and demonstrates excellent resistance to creep and cold flow, which can be weaknesses in standard PTFE.

Understanding the Trade-offs

Customization Introduces Complexity

ePTFE is not a single material but a family of materials. The degree of expansion, density, and pore size can all be tailored. This versatility means that selecting the correct grade of ePTFE for a specific application requires a deep understanding of the end-use requirements.

Porosity vs. Permeability

While hydrophobic, the porous nature of ePTFE means it is not impermeable to all substances under all conditions. High pressure can force liquids through the pores, a factor that must be considered in sealing and barrier applications.

Cost of Processing

The expansion is an additional, highly controlled manufacturing step beyond creating standard PTFE shapes. This specialized process means that ePTFE components are typically more complex and costly to produce than their non-expanded counterparts.

How to Apply This to Your Project

The decision between PTFE and ePTFE hinges entirely on whether you need the unique properties unlocked by the expansion process.

- If your primary focus is a solid, non-stick, chemically inert barrier: Standard PTFE in a solid sheet, rod, or tube is likely the most direct and cost-effective solution.

- If your primary focus is breathability, water resistance, or flexibility: The microporous structure of ePTFE is purpose-built for applications like performance textiles, medical implants, and advanced gaskets.

- If your primary focus is superior electrical insulation with a low dielectric constant: ePTFE's ability to trap air within its fibrous structure makes it the definitive choice for high-frequency cables and complex wiring systems.

By physically transforming a proven polymer, the ePTFE process creates a new class of material engineered for the most demanding applications.

Summary Table:

| Property | Standard PTFE | ePTFE |

|---|---|---|

| Structure | Solid, non-porous | Microporous, fibrous |

| Breathability | Non-breathable | Highly breathable |

| Flexibility | Stiff | Highly flexible and elastic |

| Strength | Good | Excellent strength-to-weight ratio |

| Primary Applications | Non-stick coatings, solid seals | Waterproof membranes, medical implants, advanced insulation |

Need custom ePTFE components for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE and ePTFE components for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get the exact microporous properties your project requires.

Contact our PTFE experts today to discuss how our expanded PTFE solutions can enhance your product's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability