The single most unique surface property of a PTFE bellow is its extreme non-stick nature, which stems from having the lowest surface energy and coefficient of friction of any solid material. This means other substances—whether liquids, particles, or viscous media—are naturally repelled from its surface. This prevents materials from becoming trapped in the bellow's convolutions, ensuring both cleanliness and unimpeded mechanical movement.

A PTFE bellow’s value is not just its chemical or thermal resistance, but the fact that its surface actively rejects contamination. This unique combination of a flexible, inert body with a self-cleaning, low-friction surface makes it exceptionally reliable in demanding environments.

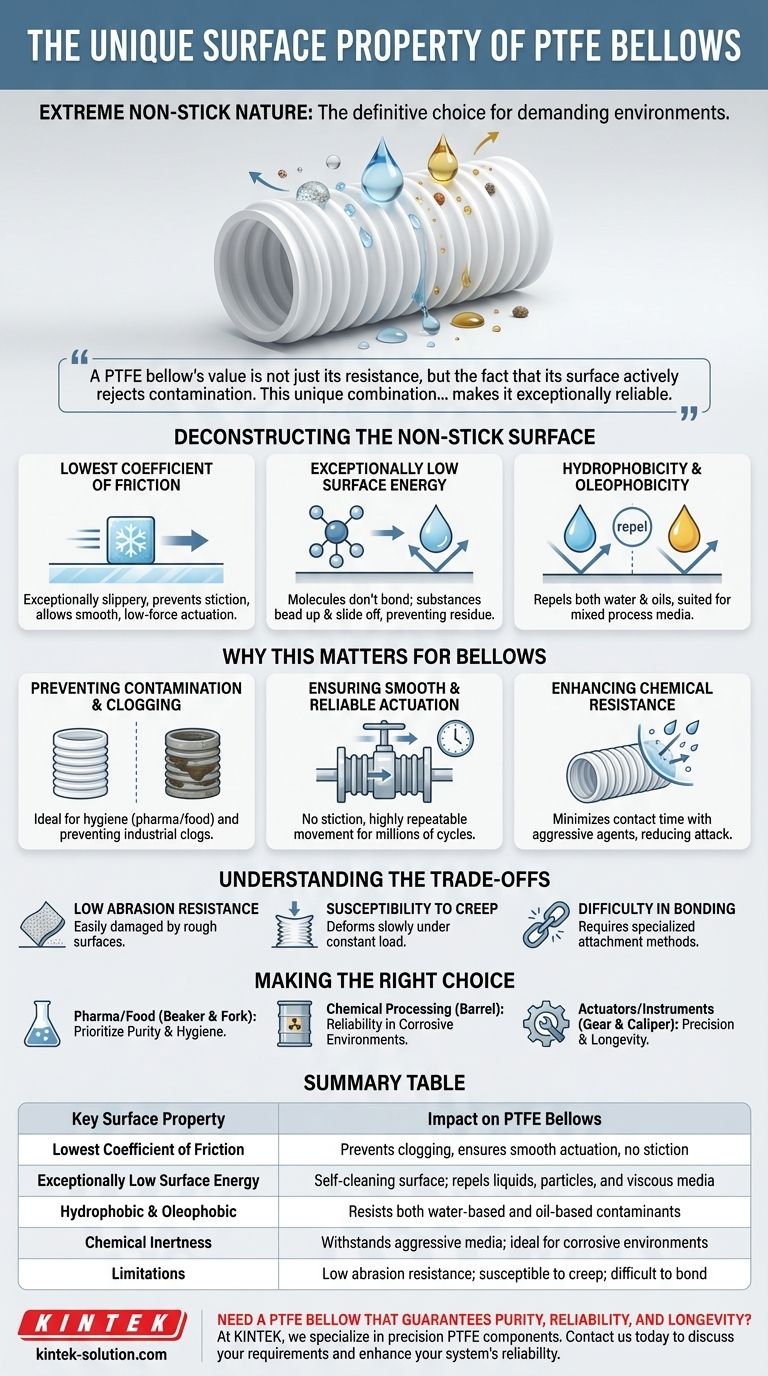

Deconstructing PTFE's Non-Stick Surface

The term "non-stick" is a functional outcome of several distinct and powerful material properties. Understanding these properties is key to understanding why PTFE is so effective.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction known for a solid material, comparable to wet ice on wet ice. This means it is exceptionally slippery.

For a bellow, this prevents particulate matter from gaining a foothold on the surface. It also ensures the bellow's convolutions do not stick to each other during compression, allowing for smooth, low-force actuation.

Exceptionally Low Surface Energy

This is the root cause of PTFE's non-stick behavior. The molecules on the surface of PTFE are not chemically "eager" to bond or interact with other molecules.

Because there is very little attractive force at the surface, other substances have nothing to adhere to. They simply bead up and slide off, a behavior that is critical for preventing residue buildup.

Hydrophobicity and Oleophobicity

A direct result of low surface energy is that PTFE is both hydrophobic (repels water) and oleophobic (repels oils).

This dual-repellent nature makes it uniquely suited for applications where process media may contain both aqueous and oil-based components, ensuring nothing clings to the bellow's surface.

Why This Matters for Bellows

These surface properties are not just academic curiosities; they translate directly into critical performance advantages for the bellow component itself.

Preventing Contamination and Clogging

In sanitary applications like food processing or pharmaceuticals, the primary benefit is hygiene. The non-stick surface prevents media from getting trapped in the folds (convolutions) of the bellow, which would otherwise create a breeding ground for bacteria.

In industrial applications, this same property prevents slurries, powders, or viscous fluids from clogging the bellow and impeding its movement or flow.

Ensuring Smooth and Reliable Actuation

Bellows are often used as flexible seals for moving parts, like valve stems. The low-friction surface ensures the bellow can expand and contract millions of times without stiction (the tendency to stick after being stationary).

This leads to highly repeatable and predictable movement, which is essential for precision instruments and actuators.

Enhancing Chemical Resistance

While PTFE's chemical inertness is a bulk property, the non-stick surface provides an additional layer of defense. Corrosive agents cannot easily adhere to the surface, which minimizes contact time and reduces the opportunity for chemical attack, even on a microscopic level.

Understanding the Trade-offs

No material is perfect. While its surface properties are exceptional, PTFE has inherent limitations that must be considered during design.

Low Abrasion Resistance

PTFE is a relatively soft material. Its low-friction surface can be easily damaged by abrasive particles or scraping against a hard, rough surface. It is not suitable for high-wear applications without reinforcement.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in sealing applications where consistent pressure is critical.

Difficulty in Bonding

The very property that makes PTFE non-stick also makes it extremely difficult to bond to other materials using conventional adhesives. Attaching PTFE bellows often requires mechanical clamping or specialized surface treatments like chemical etching to create a bondable surface.

Making the Right Choice for Your Application

Selecting a PTFE bellow is a decision to prioritize surface integrity and reliability above all else. Use its unique properties to solve specific challenges.

- If your primary focus is purity and hygiene (pharma, food): Choose PTFE for its non-stick surface that prevents buildup and ensures the system can be easily cleaned.

- If your primary focus is reliability in corrosive environments (chemical processing): Choose PTFE for its combination of chemical inertness and a surface that actively sheds aggressive media.

- If your primary focus is precision and longevity (actuators, instruments): Choose PTFE for its ultra-low friction, which guarantees smooth, repeatable movement without stiction over millions of cycles.

Ultimately, a PTFE bellow is the definitive choice for any application where the interaction between a flexible component and its surrounding environment is a potential point of failure.

Summary Table:

| Key Surface Property | Impact on PTFE Bellows |

|---|---|

| Lowest Coefficient of Friction | Prevents clogging, ensures smooth actuation, no stiction |

| Exceptionally Low Surface Energy | Self-cleaning surface; repels liquids, particles, and viscous media |

| Hydrophobic & Oleophobic | Resists both water-based and oil-based contaminants |

| Chemical Inertness | Withstands aggressive media; ideal for corrosive environments |

| Limitations | Low abrasion resistance; susceptible to creep; difficult to bond |

Need a PTFE bellow that guarantees purity, reliability, and longevity?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom bellows—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your bellow will deliver unmatched non-stick performance, chemical resistance, and smooth actuation, from prototype to high-volume production.

Contact us today to discuss your specific requirements and let our solutions enhance your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability