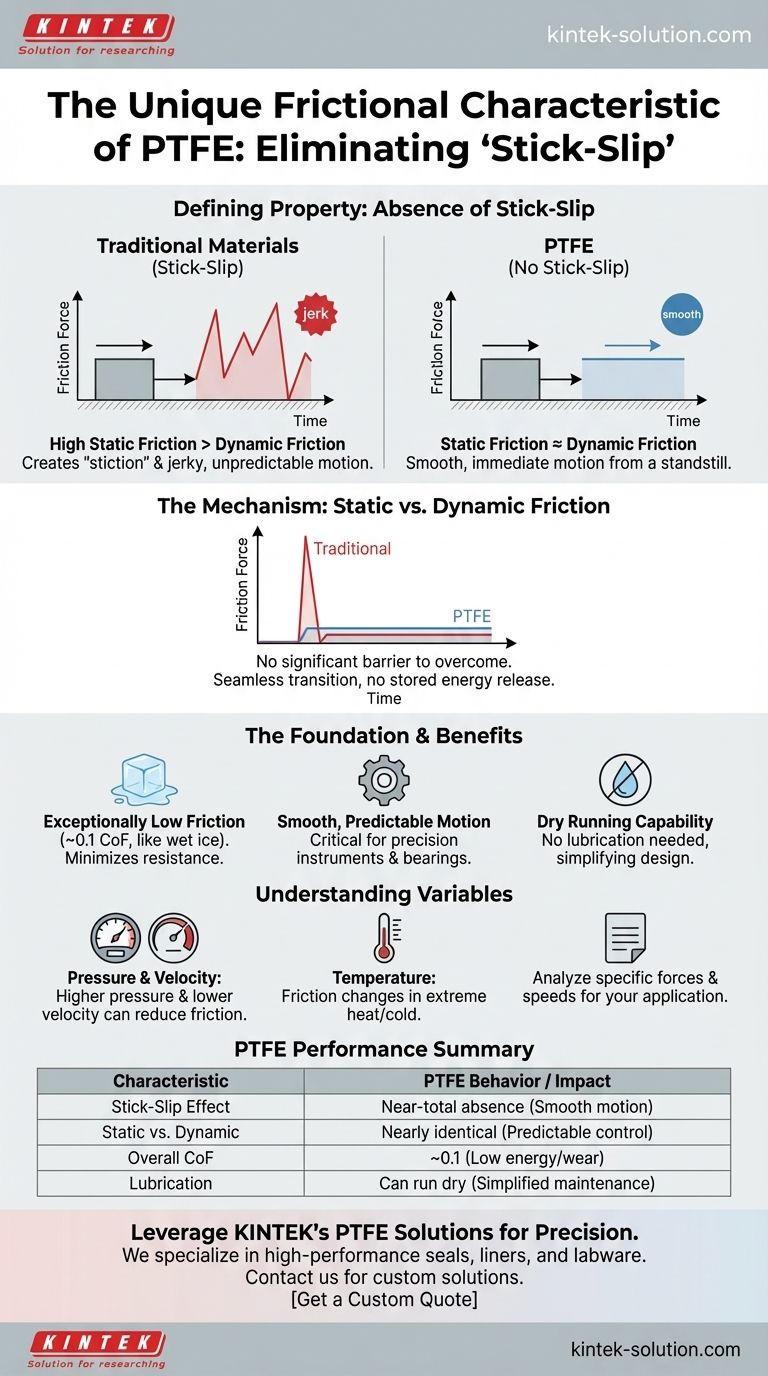

A uniquely defining frictional characteristic of PTFE is its near-total absence of "stick-slip." Unlike most materials, its static coefficient of friction (the force needed to start movement) is almost identical to its dynamic coefficient of friction (the force needed to maintain movement). This results in exceptionally smooth motion from a complete standstill, without the initial "jerk" common in other bearing materials.

While famous for its extremely low friction, PTFE's most unique frictional property is the near-elimination of stick-slip. This quality is the true source of its value in applications requiring perfectly smooth and predictable motion.

The Defining Property: Absence of Stick-Slip

The practical difference between PTFE and other materials is most obvious at the exact moment motion begins. This is due to a phenomenon known as stick-slip.

What is Stick-Slip?

For most materials, it takes more force to start an object sliding than it does to keep it sliding. This difference between static friction and dynamic friction creates a "stiction" effect.

When force is applied, it builds up until it overcomes the high static friction, causing a sudden jerk or slip. The motion then stops as the lower dynamic friction is no longer enough to sustain it, and the process repeats. This is the "stick-slip" phenomenon.

How PTFE Eliminates Stick-Slip

PTFE behaves differently. Its static friction is equal to, or only marginally higher than, its dynamic friction.

Because there is no significant frictional barrier to overcome, the transition from stop to start is exceptionally smooth and seamless. There is no stored energy to release, and therefore no jolt or chatter.

The Impact on Precision Systems

This lack of stick-slip is critical for high-precision applications. In scientific instruments, slide bearings, and hydraulic systems, any initial jerk can ruin an operation or cause premature wear.

PTFE ensures that motion starts predictably and smoothly, directly proportional to the force applied.

The Foundation: An Exceptionally Low Coefficient of Friction

While the absence of stick-slip is its most unique trait, it is enabled by PTFE's famously low overall friction.

One of the Lowest Known Values

PTFE has one of the lowest coefficients of friction of any known solid material, with a typical value around 0.1, sometimes compared to wet ice on wet ice.

This inherently slick surface is why it is the material of choice for non-stick coatings, seals, and gaskets where minimizing resistance is the primary goal.

The Benefit of Dry Running

Unlike rubber or elastomer seals, PTFE's low friction is an intrinsic property and does not depend on external lubrication.

This allows PTFE components to be used in dry-running applications, simplifying system design, reducing maintenance, and eliminating a potential point of failure or contamination.

Understanding the Trade-offs and Variables

As a technical advisor, I must emphasize that the coefficient of friction in PTFE is not a single, constant number. Its real-world performance depends on several operational factors.

Friction is Not a Constant

The quoted coefficient of friction for PTFE is a useful benchmark, but the effective friction you will experience is a function of the operating environment.

The Influence of Pressure and Velocity

The friction of PTFE responds to system variables. In many cases, higher pressures and lower sliding velocities can actually lead to a lower coefficient of friction.

This makes it crucial to analyze the specific forces and speeds in your application rather than relying on a single datasheet value.

The Role of Temperature

Temperature is another key variable that influences the frictional characteristics of PTFE. Performance can change as the system heats up or operates in extreme cold, a factor that must be considered during material selection for demanding environments.

Making the Right Choice for Your Application

To select or specify PTFE correctly, you must align its unique properties with your primary engineering goal.

- If your primary focus is smooth, jitter-free motion: The absence of stick-slip is PTFE's most important feature for you, making it ideal for precision bearings and instruments.

- If your primary focus is low-energy, low-maintenance systems: Its extremely low coefficient of friction and ability to run dry are the key benefits for applications like seals, gaskets, and self-lubricating parts.

- If your primary focus is performance under specific loads: You must evaluate how PTFE's friction will change based on your application's unique pressure, velocity, and temperature profile.

Understanding these distinct characteristics empowers you to leverage PTFE not just as a low-friction material, but as a precise engineering solution.

Summary Table:

| Characteristic | PTFE Behavior | Impact on Performance |

|---|---|---|

| Stick-Slip Effect | Near-total absence | Smooth motion from standstill, no initial jerk |

| Static vs. Dynamic Friction | Nearly identical coefficients | Predictable, proportional motion control |

| Overall Coefficient of Friction | ~0.1 (one of the lowest known) | Low energy consumption, minimal wear |

| Lubrication Requirement | Can run dry | Simplified design, reduced maintenance, no contamination |

Leverage PTFE's unique frictional properties for your precision components.

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and labware for semiconductor, medical, and industrial applications. Our precision production and custom fabrication services ensure your components deliver smooth, reliable motion without stick-slip.

Contact us today to discuss your project requirements and discover how our PTFE solutions can enhance your system's performance.

Get a Custom Quote

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries commonly use RPTFE and for what purposes? Enhance Durability in High-Load Applications

- Why is PTFE used in the chemical processing industry? Ensure Safety and Reliability in Harsh Environments

- What are the recommended PTFE formulations for the chemical processing industry and why? Optimize for Durability and Chemical Resistance

- What makes PTFE suitable for food manufacturing and packaging? Ensure Safety and Efficiency

- What is Teflon/PTFE material and what are its key properties? Unlock Its High-Performance Capabilities

- What specialized testing was performed after accelerated corrosion treatments? Quantify Material Degradation for Safety

- What is the difference between virgin PTFE and filled PTFE? Choose the Right Material for Your Application

- What is the reactivity of PTFE and why is it inert? Discover the Science Behind Its Unmatched Chemical Resistance