In essence, a PTFE liner is a high-performance inner layer or coating made from Polytetrafluoroethylene, a synthetic fluoropolymer commonly known by the brand name Teflon. It is prized for its exceptionally low friction, chemical resistance, and biocompatibility. PTFE liners are found extensively in medical devices like catheters to ensure smooth passage through the body, as well as in industrial pipes and hoses to handle corrosive chemicals without degradation.

At its core, a PTFE liner is a problem-solver for harsh environments. Its value comes from a unique combination of being incredibly slippery, chemically inert, and heat-resistant, making it the default choice for lining components that must perform reliably under demanding conditions.

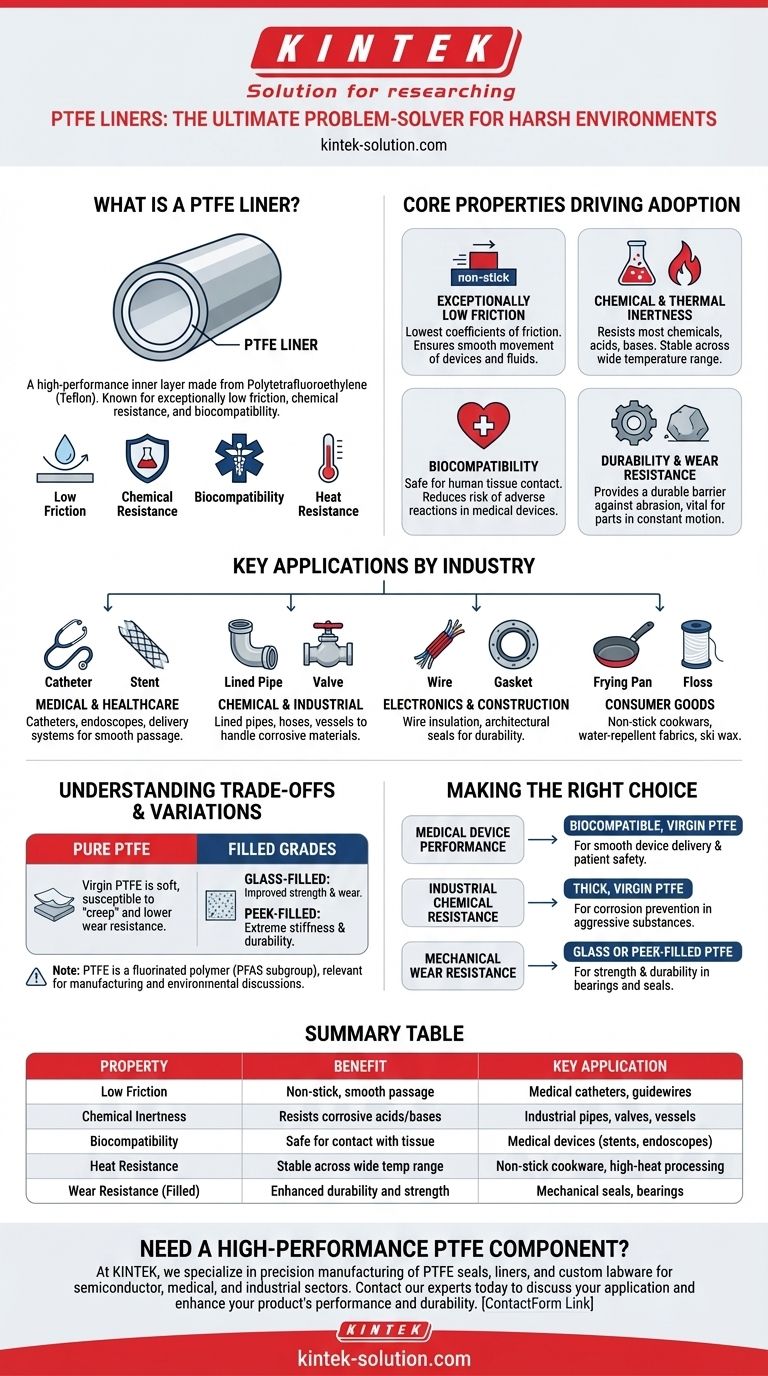

The Core Properties Driving PTFE Adoption

The widespread use of PTFE liners is not accidental. It stems from a specific set of material properties that are difficult to replicate in a single, cost-effective polymer.

Exceptionally Low Friction

A PTFE liner's most famous characteristic is its "non-stick" surface. It has one of the lowest coefficients of friction of any known solid material.

This property is critical for ensuring that devices, fluids, or parts can move along or through a component with minimal resistance.

Chemical and Thermal Inertness

PTFE is almost completely inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases.

It also maintains its integrity across a wide temperature range, making it ideal for high-heat applications like non-stick cookware and chemical processing where other materials would melt or corrode.

Biocompatibility

In medical applications, biocompatibility is non-negotiable. PTFE does not cause adverse reactions when in contact with human tissue.

This makes it a safe and reliable choice for internal medical devices like catheters, stents, and guidewires, reducing the risk of infection and tissue damage.

Durability and Wear Resistance

PTFE provides a durable barrier that protects against abrasion and wear. This is vital for guidewires that must navigate complex pathways and for industrial seals that are in constant motion.

Key Applications by Industry

PTFE's versatility allows it to be used as a liner in a remarkably diverse range of fields, from life-saving medical tools to everyday consumer goods.

Medical and Healthcare

This is a primary market for PTFE liners. They are essential components in catheters, endoscopes, and device delivery systems. The liner provides a smooth, lubricious inner channel that allows for the easy passage of surgical tools or other devices.

Chemical and Industrial Processing

In plants that handle corrosive materials, PTFE-lined pipes, hoses, valves, and vessels are standard. The liner acts as a non-reactive barrier, protecting the structural metal from being destroyed by aggressive chemicals.

Electronics and Construction

As an excellent electrical insulator, PTFE is used to line wires and cables, particularly in high-performance applications. In construction, its durability and water-repellent properties are leveraged in seals, gaskets, and architectural membranes.

Consumer Goods

The most recognized consumer application is the non-stick coating on pots and pans. PTFE is also used in high-performance, water-repellent fabrics, dental floss, and even ski wax to reduce friction.

Understanding the Trade-offs and Variations

While highly effective, PTFE is not a universal solution. Understanding its limitations and the different grades available is key to using it correctly.

Mechanical Limitations of Pure PTFE

Virgin, or pure, PTFE is relatively soft and can be susceptible to "creep"—the tendency to deform slowly under a sustained load. It also has lower wear resistance compared to harder plastics.

The Role of Filled Grades

To overcome these mechanical weaknesses, PTFE is often blended with reinforcing fillers. Glass-filled PTFE offers significantly improved strength and wear resistance. PEEK-filled PTFE combines two high-performance polymers for extreme stiffness and durability in the most demanding environments.

The PFAS Classification

It is important to note that PTFE is a type of fluorinated polymer, which is a subgroup of PFAS (per- and polyfluoroalkyl substances). This classification is relevant in discussions around manufacturing processes and environmental considerations.

Making the Right Choice for Your Goal

Selecting the correct type of PTFE liner depends entirely on the problem you need to solve.

- If your primary focus is medical device performance: A biocompatible, virgin PTFE liner is essential for ensuring smooth device delivery and patient safety.

- If your primary focus is industrial chemical resistance: A thick, virgin PTFE liner is the standard for preventing corrosion in pipes and vessels handling aggressive substances.

- If your primary focus is mechanical wear resistance: A glass-filled or PEEK-filled PTFE liner provides the necessary strength and durability for components like bearings and seals.

Ultimately, understanding PTFE's core properties allows you to leverage its unique capabilities to solve critical engineering challenges in nearly any industry.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Low Friction | Non-stick, smooth passage | Medical catheters, guidewires |

| Chemical Inertness | Resists corrosive acids/bases | Industrial pipes, valves, vessels |

| Biocompatibility | Safe for contact with tissue | Medical devices (stents, endoscopes) |

| Heat Resistance | Stable across wide temperature range | Non-stick cookware, high-heat processing |

| Wear Resistance (Filled Grades) | Enhanced durability and strength | Mechanical seals, bearings |

Need a high-performance PTFE component tailored to your specific challenge?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a biocompatible liner for a medical device, a corrosion-resistant solution for chemical processing, or a custom-fabricated part from prototype to high-volume production, our expertise ensures reliability and performance in the most demanding environments.

Contact our experts today to discuss your application and discover how our PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What customization options are available for PTFE wear strips and bands? Tailor Performance with Material, Size & Format

- What are important final considerations when machining Teflon? Mastering PTFE for Precision and Safety

- What advantages do the low friction and non-stick properties of PTFE gaskets provide? Boost System Reliability and Purity

- What are the medical applications of expanded PTFE? The Key to Advanced Biocompatible Implants

- What are the advantages of using Teflon coatings over liquid lubricants in food processing? Boost Safety & Efficiency

- What are the main applications of PTFE envelope gaskets? Seal Fragile Flanges and Prevent Contamination

- What are PTFE bushings made of? Unlocking the Power of Carbon-Fluorine Chemistry

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions