In essence, a PTFE lined check valve is a specialized, one-way valve designed to protect water pumps and maintain system integrity in demanding environments. It serves two primary functions: its core "check valve" mechanism prevents the damaging backward flow of water, while its internal Polytetrafluoroethylene (PTFE) lining provides superior protection against corrosion and contamination.

The critical takeaway is that a PTFE lined check valve is not just about controlling flow direction. It's an engineered solution that combines the mechanical necessity of a check valve with the chemical inertness of PTFE, making it essential for systems handling corrosive fluids, requiring high purity, or demanding long-term reliability with minimal maintenance.

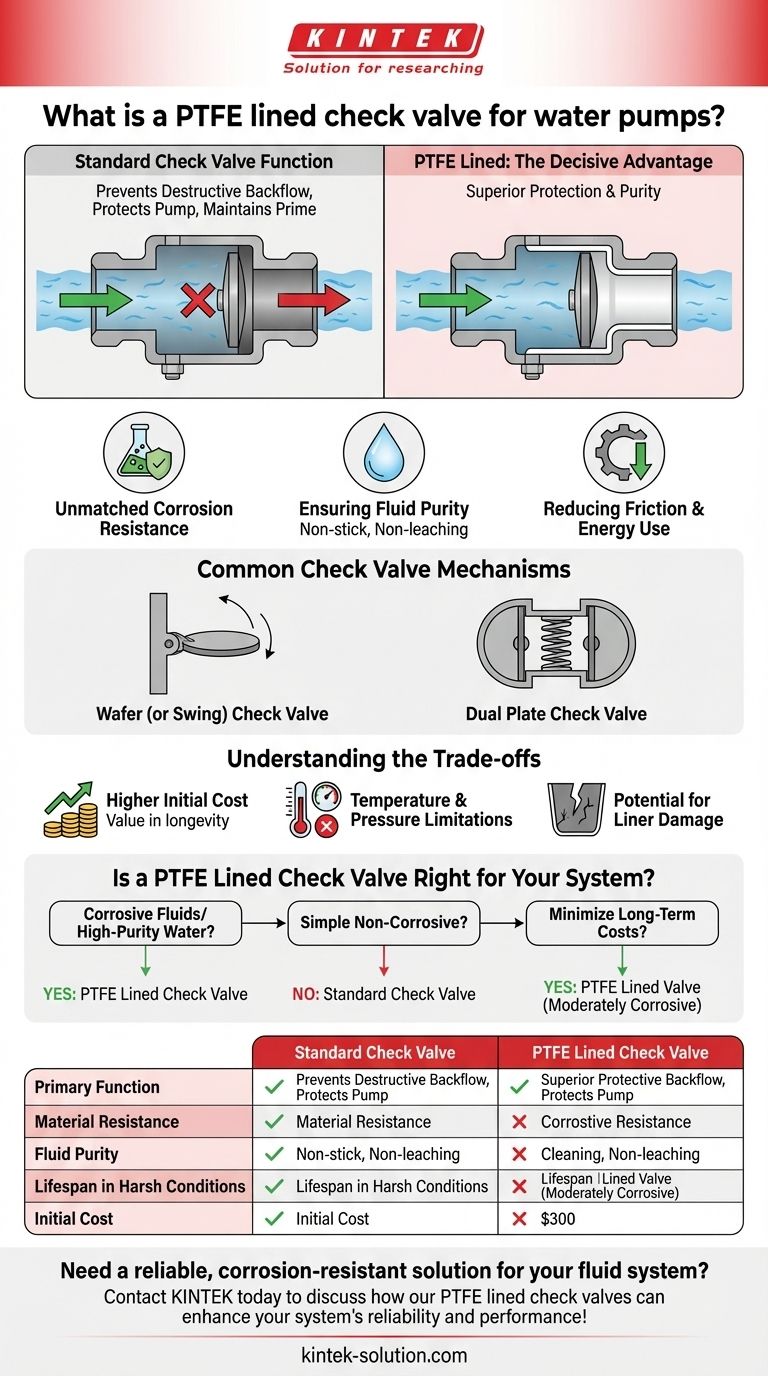

Why a Check Valve is Critical for Pumps

Before focusing on the PTFE lining, it's crucial to understand the fundamental role of the check valve itself in any pump system. It acts as a gatekeeper, ensuring fluid moves in only one direction.

Preventing Destructive Backflow

The most important job of a check valve is to automatically close when the pump shuts off. This prevents the column of water in the discharge pipe from flowing backward through the pump, a phenomenon known as backflow.

Protecting the Pump from Damage

Backflow can cause the pump's impeller to spin in reverse at high speeds, which can lead to severe mechanical damage, especially during a sudden restart. The check valve acts as a crucial safety device, guarding the pump motor and its internal components.

Maintaining System Pressure and Prime

By closing automatically, the check valve keeps the discharge line filled with water. This ensures the pump remains "primed" and ready for the next cycle, and it helps maintain steady pressure throughout the system.

The Decisive Advantage: The PTFE Lining

While any check valve can stop backflow, the PTFE lining provides a distinct set of advantages that are vital in specific applications. PTFE is a high-performance fluoropolymer, often known by the brand name Teflon.

Unmatched Corrosion Resistance

The PTFE liner creates an inert barrier between the valve's metal body and the fluid passing through it. This makes the valve exceptionally resistant to aggressive and corrosive chemicals, deionized water, or any fluid that would otherwise degrade metal components over time.

Ensuring Fluid Purity

Because PTFE is non-stick and non-leaching, it is ideal for systems where fluid purity is paramount, such as in food processing, pharmaceuticals, or high-purity water systems. It prevents metal ions or corrosion byproducts from contaminating the fluid.

Reducing Friction and Energy Use

The low-friction surface of PTFE allows the valve's internal components to move more freely. This minimal resistance to flow translates directly to lower energy consumption for the pump and reduces wear on the valve's moving parts, extending its service life.

Common Check Valve Mechanisms

PTFE linings can be applied to several check valve designs. The core principle of one-way flow remains the same, but the mechanics differ.

Wafer (or Swing) Check Valve

This common design uses a disc mounted on a hinge. Forward flow pushes the disc open like a door, and any reverse flow or gravity swings it shut against a seat to create a seal. The "wafer" style body is thin and designed to be sandwiched between two pipe flanges, making it compact and simple to install.

Dual Plate Check Valve

This design features two semi-circular plates (doors) hinged in the center and held closed by a spring. Forward pressure forces the plates to open, and when the flow stops, the spring mechanism provides a fast, non-slamming closure. This design is often favored for its quick response time and ability to minimize water hammer.

Understanding the Trade-offs

While highly effective, PTFE lined valves are a specific solution with their own set of considerations. Being aware of them is key to making an objective decision.

Higher Initial Cost

The advanced materials and manufacturing process make PTFE lined valves more expensive upfront than standard brass, stainless steel, or PVC check valves. Their value is realized through longer life and lower maintenance in corrosive environments.

Temperature and Pressure Limitations

PTFE has specific operational limits for temperature and pressure. In extreme high-temperature or high-pressure applications, the liner's integrity could be compromised, making a specialized all-metal valve a better choice.

Potential for Liner Damage

While durable, the PTFE liner can be damaged by highly abrasive slurries or improper installation (e.g., over-tightening flanges). Care must be taken to ensure the valve is specified correctly for the media and installed according to manufacturer guidelines.

Is a PTFE Lined Check Valve Right for Your System?

Choosing the right component requires matching its capabilities to your primary operational goal.

- If your primary focus is handling corrosive fluids, chemicals, or high-purity water: The PTFE lined check valve is the definitive choice to ensure system longevity and prevent contamination.

- If your primary focus is a simple, non-corrosive application (like a home sump pump): A standard, more economical brass or PVC check valve is likely sufficient and more cost-effective.

- If your primary focus is minimizing long-term operational and maintenance costs: In a moderately corrosive environment, the extended lifespan of a PTFE lined valve can easily justify its higher initial investment.

Ultimately, selecting a PTFE lined check valve is a strategic decision to protect your pump and preserve the integrity of your entire fluid system.

Summary Table:

| Feature | Standard Check Valve | PTFE Lined Check Valve |

|---|---|---|

| Primary Function | Prevents backflow | Prevents backflow AND corrosion/contamination |

| Material Resistance | Limited to non-corrosive fluids | Excellent for corrosive chemicals, high-purity water |

| Fluid Purity | Potential for metal ion leaching | Non-stick, non-leaching, ensures purity |

| Lifespan in Harsh Conditions | Shorter | Significantly longer, reduces maintenance |

| Initial Cost | Lower | Higher (justified by longevity in specific applications) |

Need a reliable, corrosion-resistant solution for your fluid system?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom check valves, seals, and liners. Our precision-engineered products are designed to protect your critical equipment in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your demanding application.

Contact KINTEK today to discuss how our PTFE lined check valves can enhance your system's reliability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How should designs account for Teflon's high creep rate? Master PTFE Design for Long-Term Reliability

- What are the main components constructed from PTFE in these valves? Ensure Ultimate Purity and Chemical Resistance

- What are the key properties of PTFE balls? Unlock Superior Performance for Demanding Applications

- What are the advantages of using Teflon coatings over liquid lubricants in food processing? Boost Safety & Efficiency

- What makes expanded PTFE gaskets easy to handle and install? Achieve a Perfect Seal on Any Flange

- What is the cost-benefit analysis of using Teflon gland packing? Maximize ROI with Low-Cost Seals

- What role do PTFE guide strips play in the aerospace industry? Ensure Safety and Reliability in Critical Systems

- What factors should be considered when selecting a PTFE-lined valve? Ensure Long-Term Reliability & Safety