At its core, a PTFE lined butterfly valve is a quarter-turn valve where all internal surfaces that contact the process fluid are protected by a layer of Polytetrafluoroethylene (PTFE). This design marries the simple, flow-controlling mechanism of a standard butterfly valve with the exceptional chemical resistance of PTFE, creating a robust solution for demanding industrial applications.

The central challenge in many industries is safely handling corrosive or high-purity fluids without the valve itself degrading or contaminating the media. A PTFE lined butterfly valve solves this by using the liner as an inert barrier, completely isolating the valve's structural metal components from the destructive or sensitive process fluid.

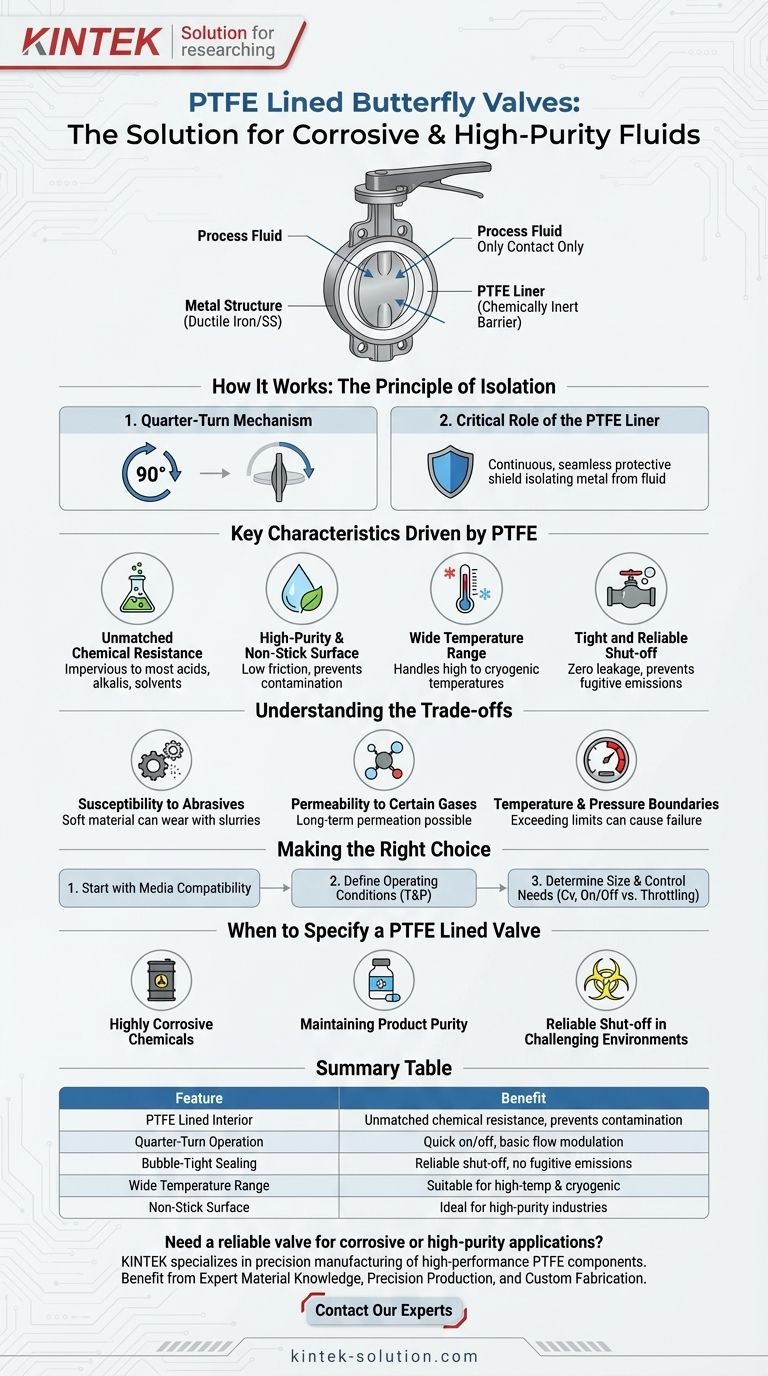

How It Works: The Principle of Isolation

A PTFE lined butterfly valve operates on a simple mechanical principle, but its true value lies in the material science of its liner. Understanding how these two aspects work together is key to appreciating its function.

The Quarter-Turn Mechanism

Like all butterfly valves, it uses a circular disc mounted on a central rod. A 90-degree turn of this rod, either by a handle or an actuator, rotates the disc from a position parallel to the flow (fully open) to perpendicular to the flow (fully closed).

This mechanism provides quick shut-off and allows for basic flow modulation, also known as throttling.

The Critical Role of the PTFE Liner

The defining feature is the molded PTFE liner that covers all "wetted" internal parts of the valve. This includes the interior of the valve body and often the entire surface of the disc and stem.

This liner creates a continuous, seamless protective shield. The process fluid—be it a harsh acid, solvent, or high-purity water—only ever touches the chemically inert PTFE, never the valve's metal body (typically ductile iron or stainless steel).

Key Characteristics Driven by PTFE

The performance advantages of this valve are directly inherited from the unique properties of its Polytetrafluoroethylene lining.

Unmatched Chemical Resistance

PTFE is virtually impervious to chemical attack from nearly all acids, alkalis, and solvents. This makes it the default choice for services where standard metal or elastomer valves would corrode and fail quickly.

High-Purity and Non-Stick Surface

The material has an extremely low coefficient of friction, creating a non-stick surface. This prevents media from adhering to the valve's internals, which is critical for preventing contamination in food, beverage, and pharmaceutical production.

Wide Temperature Range

PTFE maintains its integrity and performance across a broad spectrum of temperatures. It can handle both moderately high temperatures and cryogenic conditions, though specific ratings must always be confirmed for your application.

Tight and Reliable Shut-off

The resilience and flexibility of the PTFE liner allow it to form a tight seal against the disc. This ensures bubble-tight shut-off, preventing internal leaks and eliminating fugitive emissions to the atmosphere, which is vital for safety and environmental compliance.

Understanding the Trade-offs and Limitations

While highly effective, no single solution is perfect for every scenario. Being aware of the trade-offs is essential for proper specification.

Susceptibility to Abrasives

PTFE is a relatively soft material. In applications with heavy abrasive slurries or solids, the liner can be subject to wear over time, potentially compromising its integrity.

Permeability to Certain Gases

While liquid resistance is excellent, highly diffusive gases like wet chlorine or bromine can, over long periods, permeate the PTFE liner. For these specific, aggressive gas services, specialized valve designs may be required.

Temperature and Pressure Boundaries

Every valve has defined temperature and pressure limits. While PTFE's range is wide, it is not infinite. Exceeding the manufacturer's specified limits for the valve assembly can lead to liner failure.

Making the Right Choice for Your Application

Selecting the correct valve requires a methodical evaluation of your process conditions against the valve's capabilities.

Start with Media Compatibility

While PTFE is broadly resistant, always verify its compatibility with your specific chemical, its concentration, and its operating temperature. This is the most critical step.

Define Operating Conditions

Ensure the valve's maximum pressure and temperature ratings are well above your system's normal and potential upset conditions. Consider both the media temperature and the ambient environmental temperature.

Determine Size and Control Needs

The valve must be sized correctly for your pipe diameter and required flow rate (Cv). You must also decide if you need simple on/off control (manual lever or automated actuator) or precise flow modulation (requiring a specialized positioner).

When to Specify a PTFE Lined Butterfly Valve

- If your primary focus is handling highly corrosive chemicals: This valve provides the most cost-effective protection against aggressive media like acids and solvents, safeguarding your system's integrity.

- If your primary focus is maintaining product purity: The inert, non-stick PTFE surface prevents leaching and contamination, making it ideal for food, beverage, and pharmaceutical processes.

- If your primary focus is reliable shut-off in a challenging environment: The resilient PTFE seat ensures a tight, zero-leakage seal, crucial for handling hazardous or valuable fluids safely.

By understanding its core principle of isolation, you can confidently specify this valve to enhance the safety, purity, and longevity of your critical fluid handling systems.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Lined Interior | Provides unmatched chemical resistance and prevents contamination. |

| Quarter-Turn Operation | Enables quick on/off control and basic flow modulation. |

| Bubble-Tight Sealing | Ensures reliable shut-off and prevents fugitive emissions. |

| Wide Temperature Range | Suitable for both high-temperature and cryogenic applications. |

| Non-Stick Surface | Ideal for high-purity industries like pharmaceuticals and food & beverage. |

Need a reliable valve for corrosive or high-purity applications?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom-lined valves. We understand the critical demands of the semiconductor, medical, laboratory, and industrial sectors.

By choosing KINTEK, you benefit from:

- Expert Material Knowledge: Ensure optimal compatibility with your specific chemicals and process conditions.

- Precision Production: Receive valves built for reliable, long-lasting performance.

- Custom Fabrication: Get solutions tailored to your needs, from prototypes to high-volume orders.

Enhance your system's safety and efficiency. Contact our experts today to discuss your application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials