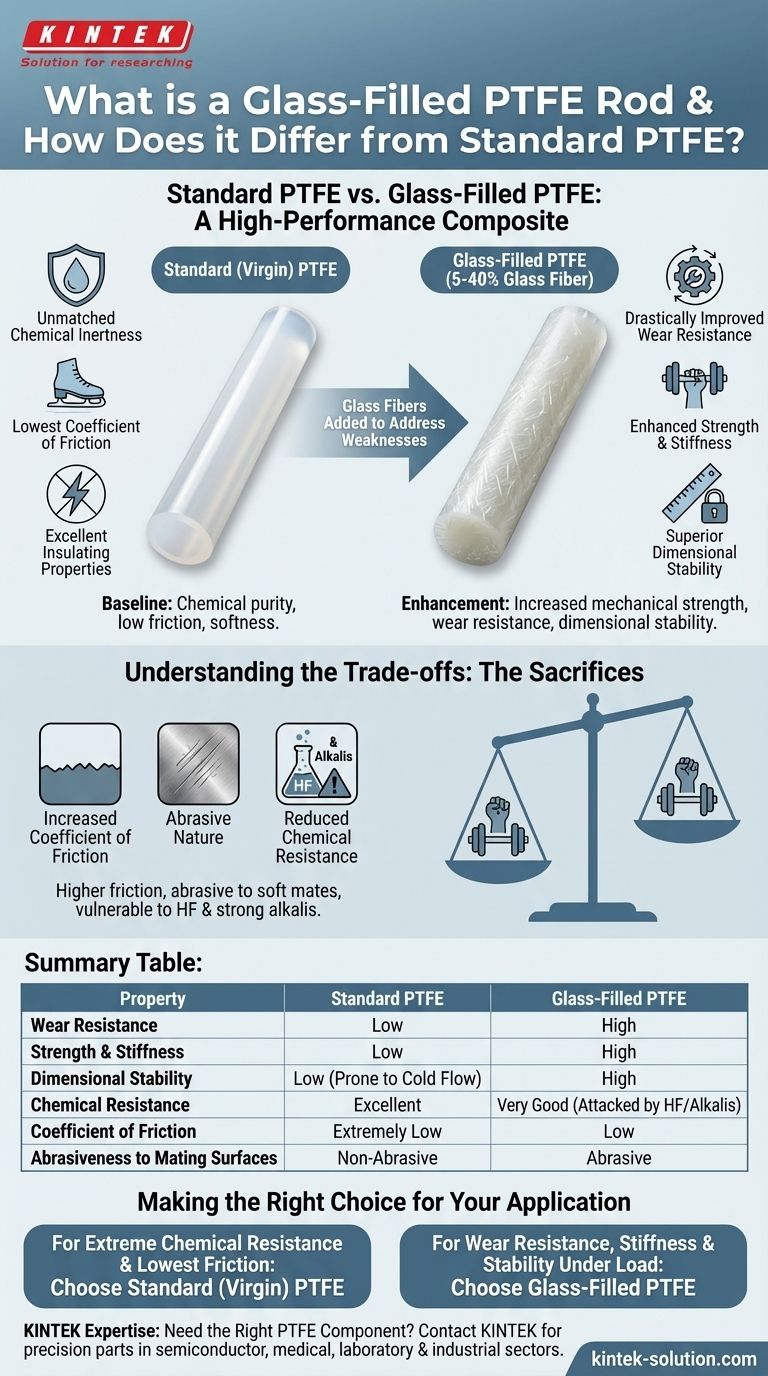

In essence, a glass-filled PTFE rod is a high-performance composite material. It takes standard Polytetrafluoroethylene (PTFE) and enhances it by embedding small glass fibers, typically between 5% and 40% by weight. This reinforcement dramatically improves the material's mechanical properties—specifically its strength, stiffness, and resistance to wear—when compared to unfilled, or "virgin," PTFE.

The core difference is a trade-off: Glass-filled PTFE sacrifices the absolute chemical purity and ultra-low friction of standard PTFE to gain significant improvements in mechanical strength, dimensional stability, and wear resistance.

The Baseline: Understanding Standard (Virgin) PTFE

To appreciate the enhancement, we must first understand the remarkable properties of the base material. Standard PTFE is known for a unique combination of characteristics that make it invaluable in many industries.

Unmatched Chemical Inertness

Virgin PTFE is virtually impervious to chemical attack. It can withstand a vast range of aggressive chemicals and extreme temperatures, making it a go-to material for seals and linings in corrosive environments.

The Lowest Coefficient of Friction

Of any known solid material, pure PTFE has one of the lowest coefficients of friction. This is the source of its famous non-stick quality, making it ideal for applications where smooth, low-resistance movement is critical.

Excellent Insulating Properties

PTFE is an excellent electrical insulator with high surface and arc resistance. It is also physiologically inert, non-toxic, and non-combustible in air.

The Enhancement: What Glass Fibers Add to PTFE

Adding glass fibers directly addresses the primary weaknesses of virgin PTFE: its softness and its tendency to deform under pressure over time.

Drastically Improved Wear Resistance

This is the most significant advantage. The embedded glass fibers create a much harder composite material that can withstand abrasive forces far better than pure PTFE, leading to a longer service life in moving parts.

Enhanced Strength and Stiffness

Glass-filling significantly reduces deformation under load. The material is much stiffer and stronger, allowing it to be used for structural components like bushings and bearings that support heavy loads without compressing or changing shape.

Superior Dimensional Stability

Standard PTFE can be prone to "cold flow," or creep, where the material slowly deforms under sustained pressure. Glass fibers reinforce the polymer matrix, drastically reducing this effect and ensuring the part maintains its shape and tolerances over time.

Understanding the Trade-offs: The Sacrifices of Glass-Filling

This enhancement in mechanical properties does not come without compromises. It is critical to understand what is lost when moving from virgin PTFE to a glass-filled composite.

Increased Coefficient of Friction

While still a low-friction material, glass-filled PTFE does not match the exceptionally low friction of the virgin polymer. The glass fibers introduce a slightly rougher, more resistant surface.

An Abrasive Nature

The embedded glass fibers are abrasive. This means glass-filled PTFE can cause wear on softer mating surfaces, such as shafts made from aluminum or softer steels. It performs best against very hard surfaces.

Reduced Chemical Resistance

The glass fibers are not as chemically inert as PTFE. Specifically, they can be attacked by hydrogen fluoride and strong alkaline chemicals. In these specific environments, virgin PTFE is the superior choice.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your application's primary demand. The choice is a direct trade-off between chemical purity and mechanical toughness.

- If your primary focus is extreme chemical resistance and the lowest possible friction: Choose standard (virgin) PTFE for applications like chemical seals, gaskets, and non-stick linings.

- If your primary focus is wear resistance, stiffness, and stability under load: Choose glass-filled PTFE for mechanical components like bearings, bushings, valve seats, and insulators.

- If your mating surface is soft or your environment contains strong alkalines: Avoid glass-filled PTFE to prevent abrasion and chemical attack, opting for virgin PTFE instead.

Ultimately, understanding this fundamental balance between inertness and strength is the key to leveraging these materials effectively in your design.

Summary Table:

| Property | Standard PTFE | Glass-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Strength & Stiffness | Low | High |

| Dimensional Stability | Low (Prone to Cold Flow) | High |

| Chemical Resistance | Excellent | Very Good (Attacked by HF/Alkalis) |

| Coefficient of Friction | Extremely Low | Low |

| Abrasiveness to Mating Surfaces | Non-Abrasive | Abrasive |

Need the Right PTFE Component for Your Demanding Application?

Whether your priority is the extreme chemical purity of virgin PTFE or the superior mechanical strength of glass-filled PTFE, KINTEK has the expertise to deliver.

We manufacture high-performance PTFE components—including seals, liners, bushings, bearings, and custom labware—for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors.

Our value to you:

- Precision Production: We ensure every part meets your exact specifications for performance and durability.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor the solution to your needs.

- Expert Guidance: Leverage our material science expertise to select the optimal PTFE grade for your application's specific demands.

Let's engineer your solution together. Contact KINTEK today for a quote or to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common applications of PTFE balls? Essential Uses in Chemical & Low-Friction Systems

- What are O-rings and their primary function? The Key to Leak-Free Sealing in Any System

- How do PTFE gaskets handle friction in flange connections? Achieve Low-Stress Sealing for Delicate Flanges

- What are the primary uses of Expanded PTFE? Unlock Its Unique Properties for Your Application

- Why is CNC machining suitable for custom Teflon parts? Achieve Precision for Demanding Applications

- Can you provide an example of PTFE expansion bellows improving safety in chemical plants? Real-World Case Study & Benefits

- What are some common PTFE products besides gasketing materials? Discover High-Performance Components

- What types of fluids are PTFE-lined pipes suitable for transporting? Handle Nearly Any Fluid with Confidence