In short, Polytetrafluoroethylene (PTFE) conforms to several critical industry specifications, most notably those governed by the FDA for food and medical contact and AMS for aerospace applications. This broad compliance makes it a highly trusted material for sensitive and high-performance environments.

The core reason PTFE meets these stringent standards is its fundamental chemical inertness and non-toxicity. This inherent stability ensures it will not react with or contaminate the substances it touches, making it a default choice for regulated industries.

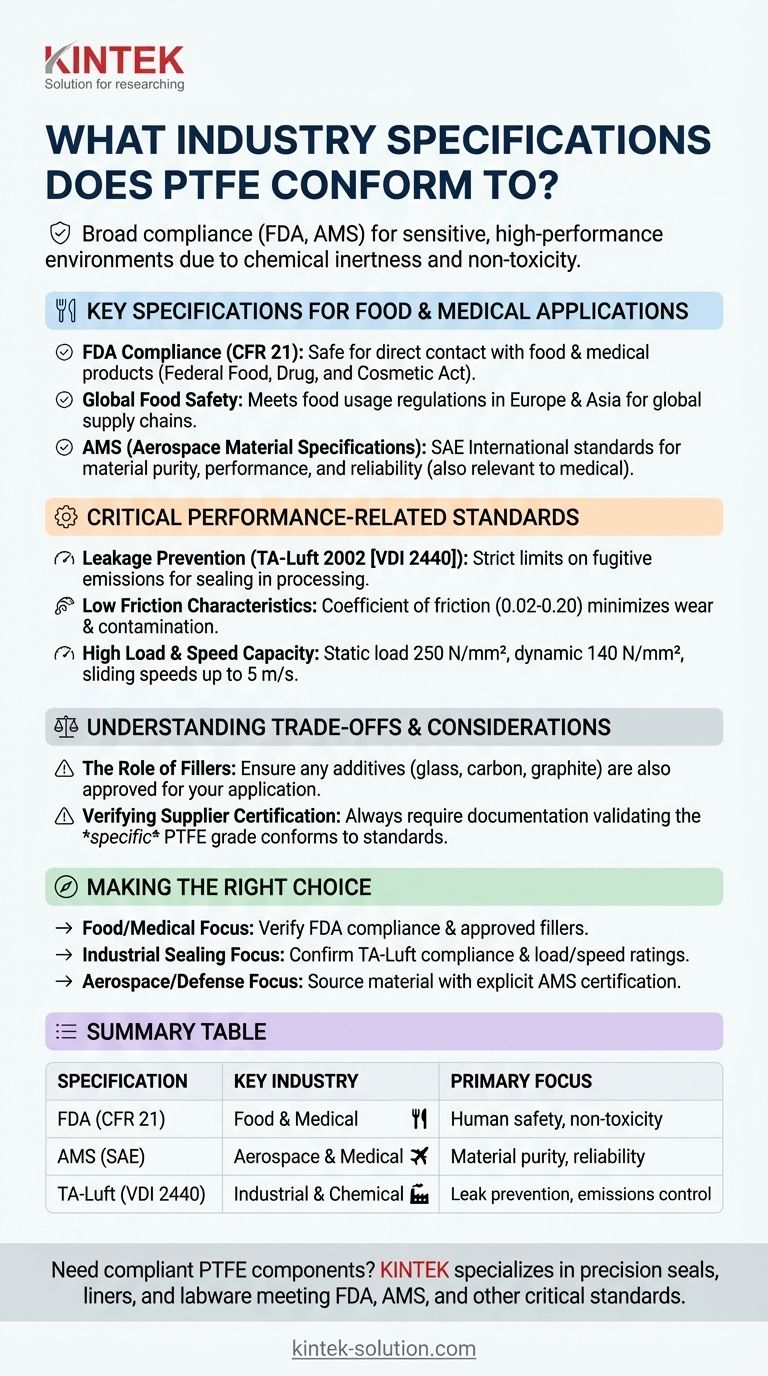

Key Specifications for Food and Medical Applications

When a material must be safe for human contact, its certifications are non-negotiable. PTFE's compliance in this area is a primary reason for its widespread use.

FDA Compliance

The most significant specification for these applications is compliance with the U.S. Food and Drug Administration (FDA).

PTFE meets the requirements of the Federal Food, Drug, and Cosmetic Act. This certifies it as safe for use in machinery and components that come into direct contact with food and medical products.

Global Food Safety Standards

Beyond the US, PTFE also meets key international standards. This includes food usage regulations in both Europe and Asia, ensuring its suitability for equipment used in global supply chains.

AMS (Aerospace Material Specifications)

While often associated with aerospace, AMS specifications are also relevant to medical applications.

These standards, published by SAE International, define the requirements for high-performance materials. Conformance indicates that PTFE meets strict criteria for material purity, performance, and reliability.

Critical Performance-Related Standards

A material's ability to meet safety standards is directly tied to its physical properties. PTFE's performance characteristics are what allow it to function reliably within regulated environments.

Leakage Prevention (TA-Luft)

PTFE conforms to the TA-Luft 2002 [VDI 2440/2200] requirements. This is a German standard for air quality control that sets strict limits on fugitive emissions and leakage.

This certification validates PTFE's effectiveness as a sealing material, which is critical for preventing contamination in food, pharmaceutical, and chemical processing.

Low Friction Characteristics

PTFE has an exceptionally low coefficient of friction, typically between 0.02 and 0.20.

This property is vital because it minimizes wear on moving parts, reducing the potential for material shedding and system contamination.

High Load and Speed Capacity

The material demonstrates impressive durability with a static load capacity of 250 N/mm² and a dynamic capacity of 140 N/mm².

It can also handle sliding speeds up to 5 m/s. These figures confirm its mechanical robustness for demanding industrial machinery.

Understanding the Trade-offs and Considerations

While highly capable, no material is without context. Understanding the nuances of PTFE is key to successful implementation.

The Role of Fillers

The references specifically mention "PTFE with fillers." Virgin PTFE is inherently compliant with standards like the FDA.

However, when fillers like glass, carbon, or graphite are added to enhance mechanical properties, you must ensure that those specific additives are also approved for your intended application.

Verifying Supplier Certification

It is crucial to understand that a material type can be compliant, but the specific product you purchase must be certified.

Always require documentation from your supplier that validates the specific grade of PTFE you are buying conforms to the standards required for your project.

Making the Right Choice for Your Application

Your final selection should be guided by the primary demands of your project.

- If your primary focus is food or medical use: Verify the material is certified as compliant with FDA regulations and ensure any fillers used are also approved.

- If your primary focus is high-performance industrial sealing: Confirm compliance with standards like TA-Luft and ensure the material's load and speed ratings meet your operational demands.

- If your primary focus is aerospace or defense: You must source material that is explicitly certified to the specific AMS standard required by your design or contract.

Ultimately, successful application depends on rigorously verifying that the specific material you procure carries the exact certifications your project requires.

Summary Table:

| Specification | Key Industry | Primary Focus |

|---|---|---|

| FDA (CFR 21) | Food & Medical | Human safety, non-toxicity |

| AMS (SAE) | Aerospace & Medical | Material purity, reliability |

| TA-Luft (VDI 2440) | Industrial & Chemical | Leak prevention, emissions control |

Need PTFE components that meet strict industry specifications? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware that are fully compliant with FDA, AMS, and other critical standards. Whether you're in the semiconductor, medical, or industrial sector, we provide custom fabrication from prototypes to high-volume orders. Contact our experts today to ensure your materials meet all necessary certifications for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability