PTFE bellows are critical components in industries where absolute chemical purity and reliable flexibility are non-negotiable. They are primarily used in the chemical processing, pharmaceutical, semiconductor, and food and beverage industries to create flexible connections that can handle highly corrosive or ultra-pure substances, accommodate vibration, and correct for misalignments in piping and equipment.

The core value of a PTFE bellow is its unique combination of properties: it provides the mechanical flexibility of a bellow while possessing the near-universal chemical inertness and high-purity characteristics of Polytetrafluoroethylene (PTFE). This makes it the default solution for fluid handling in the most demanding environments.

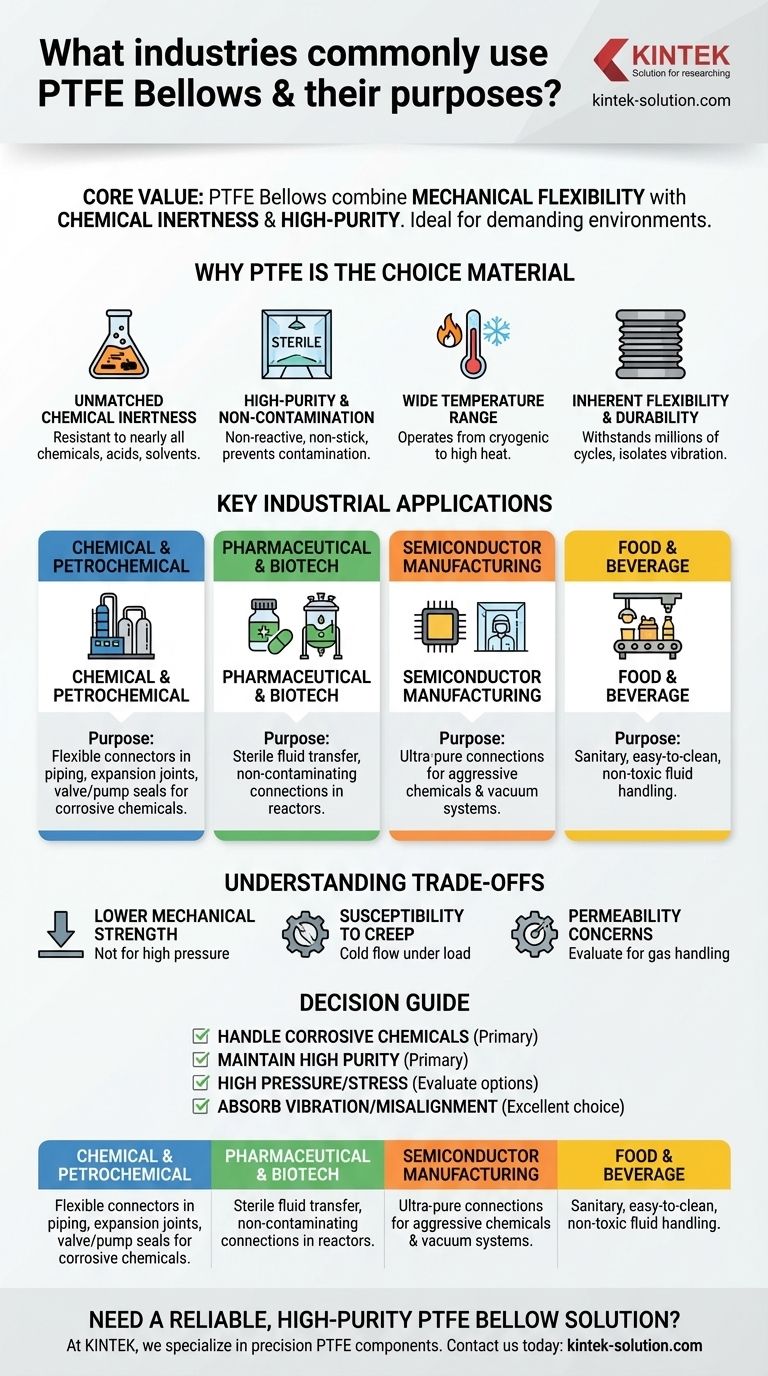

Why PTFE is the Material of Choice for Bellows

Before examining specific industries, it's essential to understand the material properties that make PTFE uniquely suited for these applications. The function of a bellow is to be a flexible, leak-proof connector, and PTFE enhances this function with several key attributes.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. This makes it an ideal material for handling aggressive media in pumps, valves, and reactors without risk of degradation.

High-Purity and Non-Contamination

The material is inherently non-reactive, non-stick, and does not leach contaminants. This is critical in applications like pharmaceutical production and semiconductor manufacturing, where even trace amounts of impurities can ruin a batch or process.

Wide Temperature Range

PTFE bellows can operate effectively in a broad range of temperatures, from cryogenic levels up to high heat. This allows them to be used in systems that experience significant thermal cycling without losing their integrity.

Inherent Flexibility and Durability

As a polymer, PTFE offers excellent flexibility and fatigue resistance. This allows the bellows to withstand millions of cycles of compression, extension, and angular movement, effectively isolating vibration and compensating for thermal expansion in a system.

Key Industrial Applications in Detail

The properties of PTFE directly translate into its use across several highly specialized industries where material failure is not an option.

Chemical and Petrochemical Processing

This is the largest and most common application. PTFE bellows are used as flexible connectors in piping systems, expansion joints to absorb thermal movement, and protective seals on valves and pumps handling corrosive chemicals.

Pharmaceutical and Biotech

In sterile manufacturing environments, PTFE bellows are used to connect equipment in reactors and fluid transfer systems. Their non-stick, non-contaminating surface ensures that aggressive or high-purity process fluids remain pure.

Semiconductor Manufacturing

The production of microchips requires ultra-pure environments and the use of highly aggressive chemicals. PTFE bellows are used in vacuum systems and chemical delivery equipment to provide flexible, non-contaminating connections that can withstand harsh etching and cleaning agents.

Food and Beverage Production

For handling food-grade liquids and ensuring sanitary conditions, PTFE bellows provide a flexible, easy-to-clean, and non-toxic solution. Their non-stick properties prevent buildup and contamination in fluid transfer lines.

Understanding the Trade-offs

While exceptionally capable, PTFE is not a universal solution. An objective assessment requires understanding its limitations compared to alternatives like metal bellows.

Lower Mechanical Strength

PTFE bellows do not possess the high-pressure ratings or tensile strength of stainless steel or other metal alloys. In high-pressure applications, a reinforced design or a different material may be necessary.

Susceptibility to Creep

Under sustained load and temperature, PTFE can be subject to "creep" or cold flow. This must be considered in the design of flanges and sealing surfaces to ensure a long-term, leak-proof connection.

Permeability Concerns

While excellent for liquids, PTFE is not completely impermeable to all gases. In high-vacuum or specific gas-handling applications, the permeation rate must be evaluated to ensure it meets system requirements.

How to Determine if PTFE Bellows are Right for Your Application

Use the following points to guide your decision-making process based on your primary engineering challenge.

- If your primary focus is handling corrosive chemicals: PTFE is almost certainly the superior choice due to its unmatched chemical inertness.

- If your primary focus is maintaining high purity: PTFE is the ideal material for preventing product contamination in pharmaceutical, semiconductor, or food-grade applications.

- If your primary focus is high pressure or high mechanical stress: You should carefully evaluate your pressure requirements and consider metal bellows or specially reinforced PTFE bellows.

- If your primary focus is absorbing vibration or misalignment: PTFE bellows offer an excellent, durable solution, particularly when chemical compatibility is also a concern.

Ultimately, PTFE bellows provide an unparalleled solution for flexible connections in the world's most demanding chemical and high-purity environments.

Summary Table:

| Industry | Primary Purpose of PTFE Bellows |

|---|---|

| Chemical & Petrochemical | Handling corrosive chemicals; absorbing thermal expansion and vibration in piping systems. |

| Pharmaceutical & Biotech | Ensuring sterile, non-contaminating fluid transfer in reactors and process equipment. |

| Semiconductor Manufacturing | Providing ultra-pure, flexible connections for aggressive chemicals and vacuum systems. |

| Food & Beverage | Maintaining sanitary conditions with easy-to-clean, non-toxic fluid handling. |

Need a reliable, high-purity PTFE bellow solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom bellows, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders to meet your exact specifications for chemical resistance and purity.

Contact us today to discuss how our PTFE expertise can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry