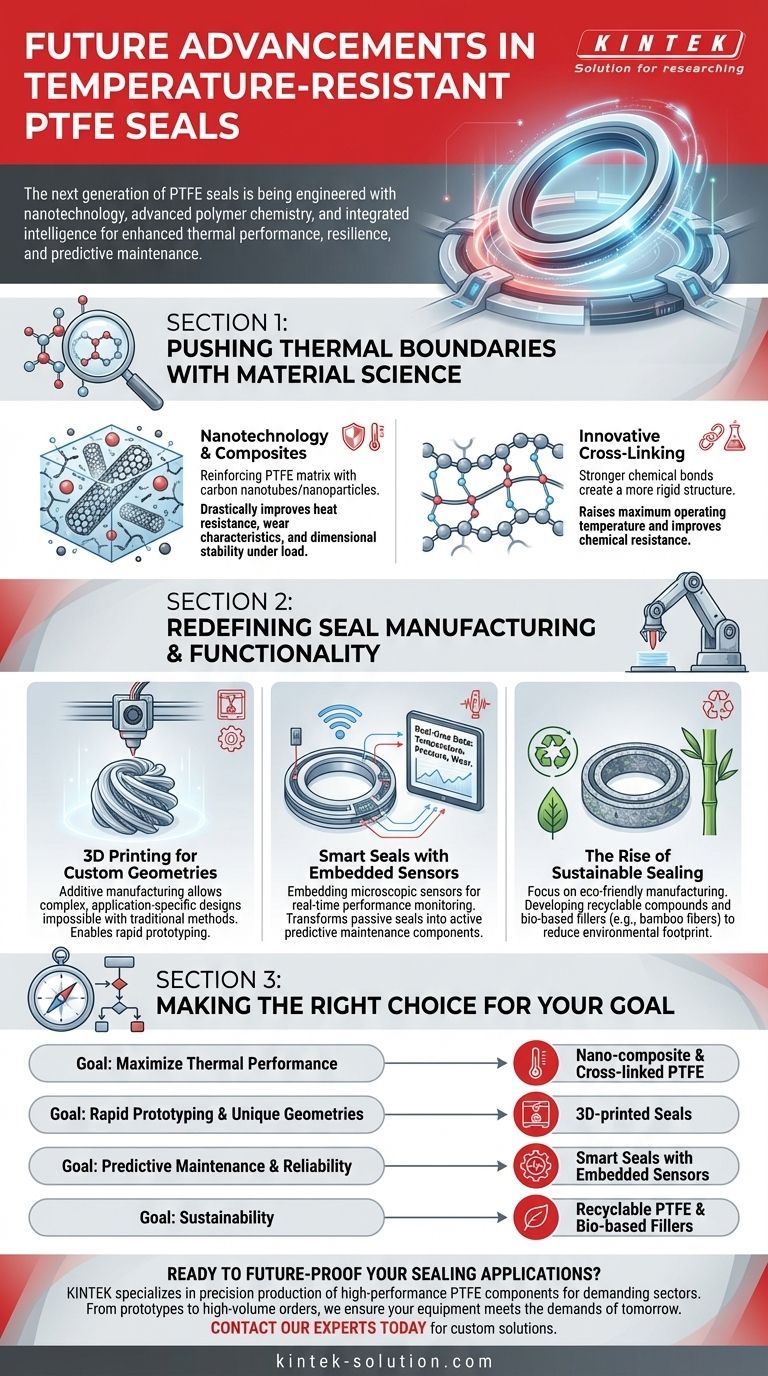

The next generation of PTFE seals is being engineered with nanotechnology, advanced polymer chemistry, and integrated intelligence. These advancements are set to dramatically increase thermal performance beyond current limits, enabling new applications in extreme environments and introducing functionalities like real-time performance monitoring.

The future of sealing technology is not just about withstanding higher temperatures; it's about creating smarter, more resilient, and highly customized components that integrate seamlessly into predictive maintenance and sustainable manufacturing systems.

Pushing Thermal Boundaries with Material Science

The core of future innovation lies in fundamentally re-engineering the PTFE material itself. The goal is to enhance its inherent thermal stability and mechanical strength without compromising its desirable low-friction properties.

Nanotechnology and Composites

The most significant leap forward comes from nano-composites. By reinforcing the PTFE matrix with materials like carbon nanotubes or other nanoparticles, engineers can dramatically improve heat resistance, wear characteristics, and dimensional stability under load. These additives act like microscopic rebar, strengthening the polymer structure at a molecular level.

Innovative Cross-Linking

New cross-linking techniques are being developed to create stronger chemical bonds within the PTFE polymer chains. This process makes the material more rigid and less susceptible to thermal degradation, effectively raising its maximum operating temperature and improving its resistance to chemical attack.

Redefining Seal Manufacturing and Functionality

Beyond raw material improvements, advancements in how seals are made and what they can do are changing the landscape. These shifts focus on customization, intelligence, and environmental responsibility.

3D Printing for Custom Geometries

Additive manufacturing, or 3D printing, is poised to revolutionize seal design. It allows for the creation of complex, application-specific geometries that are impossible to produce with traditional molding or machining, enabling rapid prototyping and highly optimized sealing solutions.

Smart Seals with Embedded Sensors

The concept of the "smart seal" involves embedding microscopic sensors directly into the sealing material. These sensors can provide real-time data on temperature, pressure, and wear, transforming the seal from a passive component into an active part of a predictive maintenance system.

The Rise of Sustainable Sealing

There is a growing focus on eco-friendly manufacturing. This includes developing recyclable PTFE compounds and experimenting with bio-based fillers, such as bamboo fibers, to reduce the environmental footprint without sacrificing performance in certain applications.

Understanding the Practical Considerations

While these advancements are promising, their successful implementation depends on a holistic approach that balances new materials with proven engineering principles.

Material Properties vs. Mechanical Design

Even the most advanced material will fail if not supported by proper mechanical design. The design of sealing pockets and cavities remains critical to accommodate the plastic nature of PTFE. A poorly designed housing can cause a state-of-the-art seal to leak or fail prematurely.

The Cost-Performance Equation

New technologies invariably come with higher initial costs. Adopting nano-composite or smart seals will require a careful analysis of the long-term value, weighing the upfront investment against benefits like extended service life, reduced downtime, and enhanced safety.

Validation and Standardization

As these new materials become available, they will require rigorous testing and validation to establish new performance standards. Early adopters will need to work closely with manufacturers to ensure the technology is suitable and reliable for their specific critical applications.

Making the Right Choice for Your Goal

To prepare for these advancements, align your focus with the technology that best solves your core challenge.

- If your primary focus is maximizing thermal performance: Keep a close watch on the development of nano-composite and cross-linked PTFE formulations.

- If your primary focus is rapid prototyping or unique geometries: Begin exploring the capabilities and material options available in 3D-printed seals.

- If your primary focus is predictive maintenance and reliability: Investigate the emerging field of smart seals with embedded sensor technology.

- If your primary focus is sustainability: Inquire with suppliers about their roadmaps for recyclable PTFE and the use of bio-based fillers.

Ultimately, these innovations empower engineers to solve sealing challenges that were once considered impossible.

Summary Table:

| Advancement Area | Key Innovation | Expected Impact |

|---|---|---|

| Material Science | Nano-composites & Cross-linking | Higher thermal stability, improved wear resistance |

| Manufacturing | 3D Printing | Custom, complex geometries; rapid prototyping |

| Functionality | Embedded Sensors (Smart Seals) | Real-time performance data for predictive maintenance |

| Sustainability | Recyclable Compounds & Bio-fillers | Reduced environmental footprint |

Ready to Future-Proof Your Sealing Applications?

As a leading manufacturer of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors, KINTEK is at the forefront of these advancements. We specialize in precision production and custom fabrication—from prototypes to high-volume orders—ensuring your equipment meets the demands of tomorrow, today.

Let's discuss how next-generation PTFE seals can enhance your system's reliability, efficiency, and intelligence. Contact our experts today to explore custom solutions for your most challenging environments.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the chemical stability of PTFE oil seals compare to conventional oil seals? Superior Performance in Harsh Environments

- Why is the non-reactivity of PTFE fasteners important in medical devices? Ensuring Patient Safety and Device Integrity

- Why are Teflon bushings essential for machinery? Reduce Friction, Maintenance, and Costs

- What is a lip seal and how does it function? A Guide to Reliable Shaft Sealing

- What are the key advantages of using PTFE valves in the chemical industry? Enhance Safety and Purity

- In which industries are PTFE envelope gaskets commonly used? A Guide to Chemical Resistance and Purity

- What makes PTFE bushes durable in extreme conditions? Unmatched Thermal & Chemical Stability

- What are the advantages of PTFE machined bellows? Achieve Superior Chemical Resistance & Purity