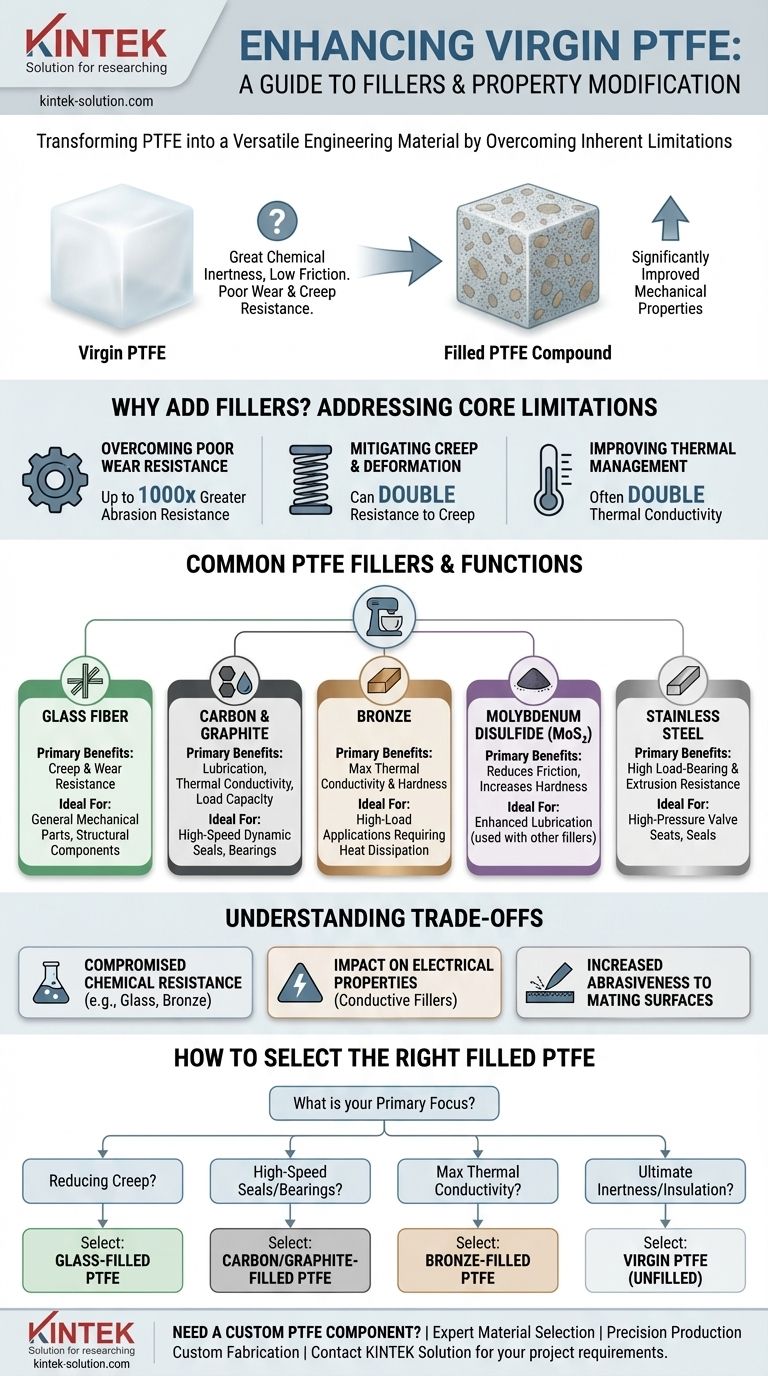

To enhance the inherent properties of Virgin PTFE, a range of fillers can be compounded into the base resin. The most common of these include glass fiber, carbon, graphite, bronze, and molybdenum disulfide (MoS₂). These materials are added to significantly improve mechanical properties such as wear resistance, creep resistance, and thermal conductivity, transforming PTFE into a versatile engineering material for demanding applications.

Virgin PTFE is an exceptional material known for its chemical inertness and low friction, but it suffers from poor resistance to wear and deformation under load. Fillers are the strategic solution, creating composite materials that retain PTFE's core benefits while overcoming its mechanical weaknesses.

The Purpose of PTFE Fillers: Addressing Core Limitations

Adding fillers is not about changing what PTFE is, but rather about mitigating its natural limitations. The improvements generally fall into three key categories.

Overcoming Poor Wear Resistance

Virgin PTFE is relatively soft and can wear quickly in dynamic applications. Fillers create a reinforced matrix that dramatically increases durability.

Some studies show that filled PTFE grades can offer up to 1000 times greater abrasion resistance than their unfilled counterparts, making them suitable for bearings, seals, and wear rings.

Mitigating Creep and Deformation

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. Virgin PTFE is highly susceptible to creep, especially under load and at elevated temperatures.

Fillers act as a rigid internal skeleton, providing structural support that can more than double the material's resistance to creep.

Improving Thermal Management

PTFE is an excellent thermal insulator, which can be a drawback in high-speed applications where friction generates heat. This trapped heat can accelerate wear and cause component failure.

Thermally conductive fillers like bronze or carbon create a path for heat to dissipate away from the contact surface, often doubling the thermal conductivity of the material.

A Guide to Common PTFE Fillers and Their Functions

Each filler imparts a unique set of characteristics to the PTFE compound. The choice depends entirely on the specific demands of the application environment.

Glass Fiber

Glass fiber is one of the most common fillers. It primarily provides a significant improvement in creep resistance and general wear resistance. It is a good, all-around choice for many mechanical applications.

Carbon & Graphite

Carbon and graphite are often used together. Carbon increases hardness, load-bearing capability, and creep resistance. Graphite is a dry lubricant, which enhances the material's low-friction properties, making it ideal for high-speed, dynamic applications.

These fillers also provide good thermal conductivity and are chemically resistant in non-oxidizing environments.

Bronze

Bronze is added to dramatically increase thermal conductivity and hardness. This makes it an excellent choice for applications where heat dissipation from a bearing or seal surface is critical. It also provides excellent wear and creep resistance.

Molybdenum Disulfide (MoS₂)

Often called "moly," MoS₂ acts as a dry lubricant, similar to graphite. It is frequently used in smaller quantities alongside other fillers like glass or bronze to reduce the coefficient of friction and improve hardness.

Stainless Steel

For applications demanding high load-bearing capacity and extrusion resistance, stainless steel fillers are used. They produce a very strong, rigid material commonly found in high-pressure valve seats and seals.

Understanding the Trade-offs

While fillers provide significant benefits, they also introduce critical trade-offs that must be considered during material selection.

Compromised Chemical Resistance

The exceptional chemical inertness of PTFE can be diminished by the filler. For example, glass fibers can be attacked by strong alkalis, while bronze is susceptible to certain acids and corrosive agents that Virgin PTFE would easily resist.

Impact on Electrical Properties

Virgin PTFE is an outstanding electrical insulator. Adding conductive fillers like carbon, graphite, or bronze will fundamentally alter these properties, making the material statically dissipative or even conductive.

Increased Abrasiveness to Mating Surfaces

Hard fillers, particularly glass fiber, can be more abrasive to the counter-surfaces they run against, such as soft metal shafts. This is a system-level consideration; the material of both components must be compatible.

How to Select the Right Filled PTFE

Choosing the correct material requires aligning the filler's primary benefit with your application's most critical challenge.

- If your primary focus is reducing deformation under static load (creep): Select Glass-filled PTFE for its excellent structural rigidity.

- If your primary focus is high-speed dynamic seals or bearings: Choose Carbon/Graphite-filled PTFE for its self-lubricating properties and good thermal conductivity.

- If your primary focus is maximum thermal conductivity in high-load applications: Bronze-filled PTFE is the optimal choice for dissipating frictional heat.

- If your primary focus is ultimate chemical inertness or electrical insulation: You must use Virgin (unfilled) PTFE, as any filler will compromise these properties.

By understanding these strategic enhancements, you can specify a PTFE component perfectly engineered to its operational demands.

Summary Table:

| Filler Type | Primary Benefits | Ideal For |

|---|---|---|

| Glass Fiber | Improves creep resistance & wear resistance | General mechanical parts, structural components |

| Carbon/Graphite | Enhances lubrication, thermal conductivity, & load capacity | High-speed dynamic seals, bearings |

| Bronze | Maximizes thermal conductivity & hardness | High-load applications requiring heat dissipation |

| Molybdenum Disulfide (MoS₂) | Reduces friction & increases hardness | Used alongside other fillers for enhanced lubrication |

| Stainless Steel | Provides high load-bearing & extrusion resistance | High-pressure valve seats and seals |

Need a Custom PTFE Component for Your Demanding Application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that the right filler is critical to your component's success.

We provide:

- Expert Material Selection: Leverage our deep knowledge of filled PTFE to choose the optimal compound (glass, carbon, bronze, etc.) for your specific needs in wear resistance, creep resistance, or thermal management.

- Precision Production: We prioritize manufacturing accuracy to ensure your components perform reliably.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor the solution to your exact specifications.

Let us help you engineer a component that overcomes the limitations of standard PTFE. Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency