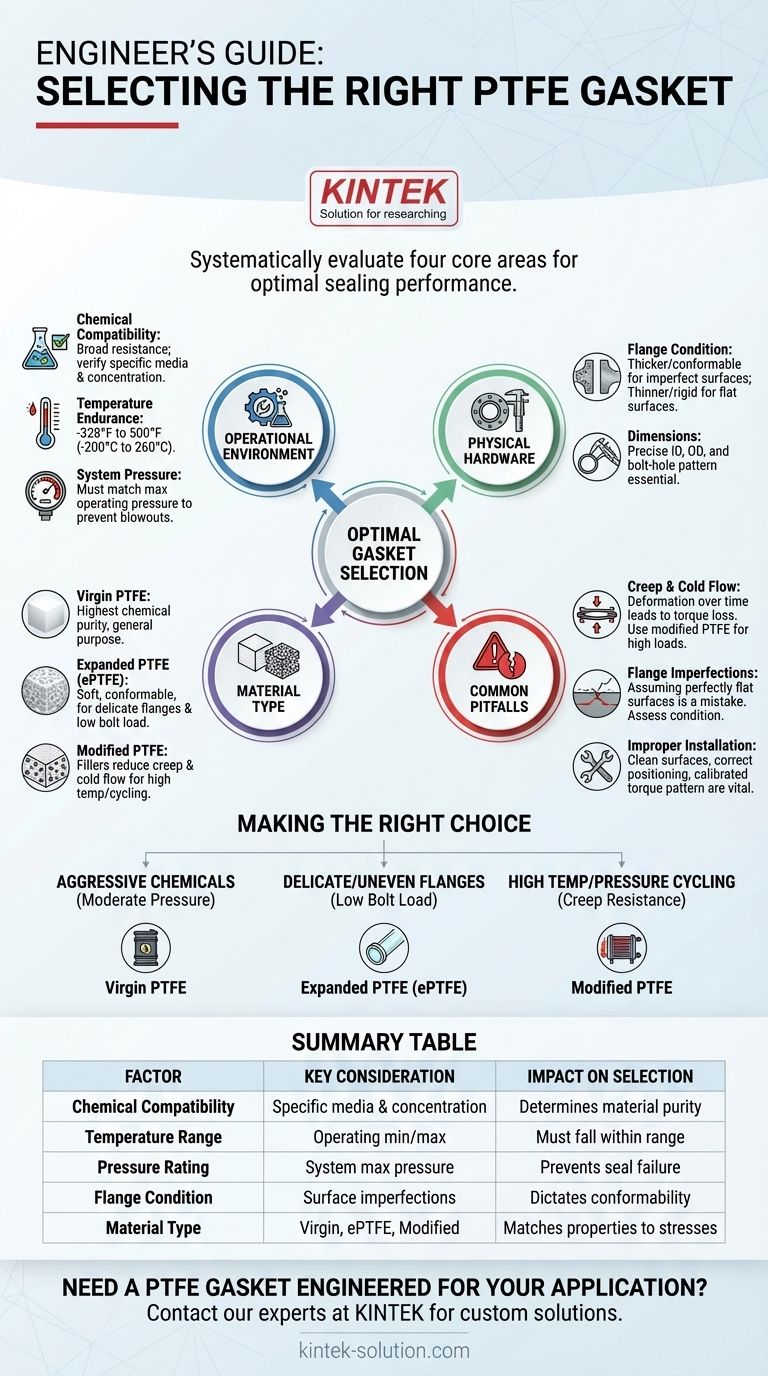

To select the correct PTFE gasket, an engineer must systematically evaluate four core areas: the specific type of PTFE material, the operational demands of the application (temperature, pressure, and chemical media), the physical condition of the flanges, and the precise physical dimensions required for the seal.

The optimal PTFE gasket is not simply the one with the highest specifications, but the one whose properties are precisely matched to your system's unique chemical, thermal, and mechanical stresses. Overlooking a single factor, such as flange surface condition or pressure rating, can compromise the integrity of the entire seal.

Analyzing Your Operational Environment

The performance of any gasket is dictated by the environment in which it operates. Before selecting a material type, you must have a clear and accurate understanding of your system's conditions.

Chemical Compatibility

PTFE is renowned for its exceptional chemical resilience, making it inert to nearly all industrial chemicals.

This broad resistance allows it to be used in highly corrosive environments where other materials would quickly degrade. However, you must always verify compatibility with your specific media, especially in high-concentration or high-temperature applications.

Temperature Endurance

PTFE gaskets operate effectively across an extremely wide thermal range, typically from -328°F to 500°F (-200°C to 260°C).

This makes them suitable for applications ranging from cryogenic processes to high-temperature chemical processing. Ensure your system's minimum and maximum temperatures fall comfortably within the gasket's specified range.

System Pressure Ratings

A gasket's ability to withstand pressure is a critical, non-negotiable parameter.

Selecting a gasket without confirming its pressure rating for your specific application is a primary cause of seal failure and potential blowouts. This specification must be cross-referenced with your system's maximum operating pressure.

Matching the Gasket to the Physical Hardware

A theoretically perfect gasket will fail if it does not physically match the hardware it is intended to seal. The mechanical interface between the gasket and the flanges is just as important as the material's chemical properties.

The Role of Flange Condition

The surface of your flanges dictates the necessary thickness and compressibility of the gasket.

Thicker, more conformable gaskets are better suited for sealing flanges that have minor pitting, warping, or uneven surfaces. Conversely, thinner, more rigid gaskets are stronger and preferable for perfectly flat, smooth surfaces in high-pressure systems.

Selecting the Correct Dimensions

Choosing the incorrect size is a fundamental error that guarantees a leak path.

The inner and outer diameters, as well as the bolt-hole pattern, must be specified precisely to ensure the gasket seats correctly and provides a uniform sealing pressure across the flange face.

Virgin vs. Expanded vs. Modified PTFE

Not all PTFE is the same. The manufacturing process creates different properties for specific needs.

- Virgin PTFE is pure, unfilled polytetrafluoroethylene. It offers the highest chemical resistance and is a general-purpose standard.

- Expanded PTFE (ePTFE) is softer and more conformable. It is ideal for delicate flanges (e.g., glass-lined) or applications requiring a strong seal with lower bolt torque.

- Modified PTFE includes fillers (like silica or glass) to enhance specific properties, most notably reducing creep and cold flow in high-temperature or pressure-cycling applications.

Common Pitfalls to Avoid

Even with its robust properties, incorrect selection or installation of a PTFE gasket can lead to system failure. Understanding these common mistakes is critical for ensuring a reliable seal.

Overlooking Creep and Cold Flow

Standard PTFE can be susceptible to "cold flow," where the material deforms over time under pressure. This can lead to a loss of bolt torque and subsequent leakage. For applications with high loads or significant temperature cycling, a modified PTFE is essential.

Ignoring Flange Imperfections

Assuming flanges are perfectly flat is a frequent mistake. Using a rigid, thin gasket on a slightly warped or scratched flange face creates an incomplete seal from the start. Always assess the surface condition before specifying gasket thickness and type.

Assuming a Perfect Installation

The most carefully selected gasket will fail if installed improperly. Proper installation technique—including clean flange surfaces, correct gasket positioning, and a calibrated, crisscross bolt-tightening pattern—is fundamental to achieving a reliable seal.

Making the Right Choice for Your Application

Your final selection should be a direct response to the primary challenge of your sealing application. Use these guidelines to steer your decision.

- If your primary focus is sealing aggressive chemicals at moderate pressures: Virgin PTFE offers the highest chemical purity and is often the most cost-effective and reliable choice.

- If your primary focus is sealing delicate or uneven flanges (like glass-lined steel): Expanded PTFE provides excellent conformability with lower required bolt loads, preventing hardware damage.

- If your primary focus is managing high temperatures with significant pressure cycling: A modified PTFE gasket is engineered to resist creep and cold flow, maintaining seal integrity over time.

By treating gasket selection as a critical engineering decision, you ensure the long-term reliability and safety of your entire system.

Summary Table:

| Factor | Key Consideration | Impact on Selection |

|---|---|---|

| Chemical Compatibility | Specific media and concentration | Determines material purity (e.g., Virgin PTFE for high purity) |

| Temperature Range | Operating min/max temperatures | Must fall within -328°F to 500°F (-200°C to 260°C) range |

| Pressure Rating | System's maximum operating pressure | Prevents seal failure and blowouts; affects gasket thickness |

| Flange Condition | Surface flatness and imperfections | Dictates gasket conformability (ePTFE for uneven surfaces) |

| Material Type | Virgin, Expanded (ePTFE), or Modified PTFE | Matches properties to application stresses (e.g., creep resistance) |

Need a PTFE gasket engineered for your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gaskets, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide solutions tailored to your unique chemical, thermal, and mechanical requirements—from prototypes to high-volume orders.

Contact our experts today to discuss your project and ensure a reliable, long-lasting seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments