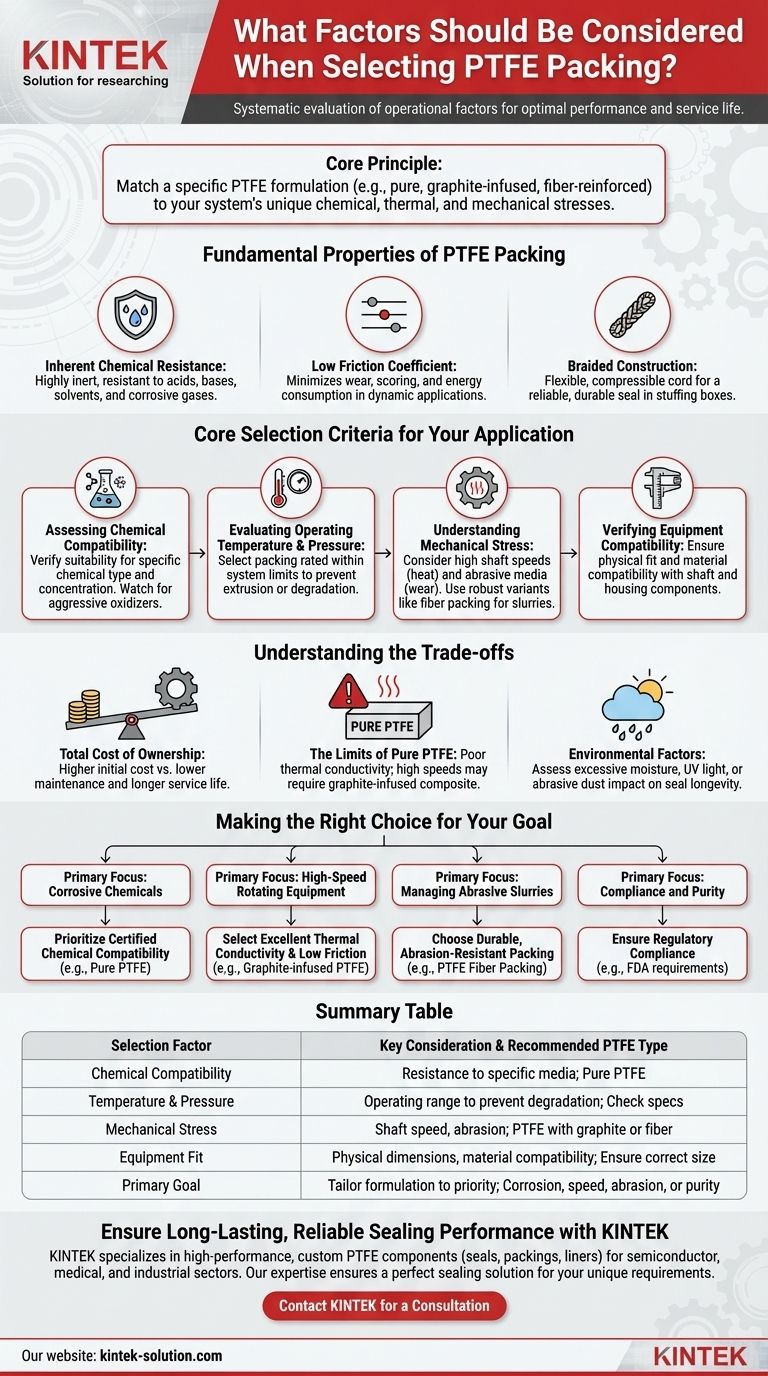

When selecting the appropriate PTFE packing, you must systematically evaluate five critical operational factors: the chemical environment, operating temperature and pressure, mechanical stress from shaft speed or media, and compatibility with your specific equipment. This evaluation ensures the packing's material properties are precisely matched to the application's demands, preventing premature failure and maximizing service life.

The core principle of selecting PTFE packing is not about finding a single "best" option, but about matching a specific formulation—such as pure PTFE, graphite-infused, or fiber-reinforced—to the unique chemical, thermal, and mechanical stresses of your system.

The Fundamental Properties of PTFE Packing

Polytetrafluoroethylene (PTFE) is a synthetic polymer known for its exceptional characteristics, which make it a premier choice for demanding industrial sealing applications.

Inherent Chemical Resistance

PTFE is highly inert and resistant to nearly all industrial chemicals, including concentrated acids, bases, solvents, and corrosive gases. This makes it a default choice for systems handling aggressive media where other materials would quickly degrade.

Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material. This property is critical in dynamic applications, as it minimizes wear and scoring on rotating shafts and reduces the energy required to power the equipment.

Braided Construction

For use as packing, PTFE is typically lubricated and braided into a flexible, compressible cord. This construction allows it to conform tightly within a stuffing box, creating a reliable and durable seal against leakage.

Core Selection Criteria for Your Application

A successful selection requires a detailed analysis of your operational environment. Overlooking any one of these factors can lead to seal failure, equipment damage, and costly downtime.

Assessing Chemical Compatibility

While PTFE is broadly resistant, you must verify its suitability for the specific chemical type and concentration in your system. Certain aggressive oxidizers or molten alkali metals may require specialized packing formulations.

Evaluating Operating Temperature and Pressure

Each PTFE packing has a defined temperature and pressure limit. Exceeding these limits can cause the packing to extrude, degrade, or lose its sealing capability. Always select a packing rated well within your system's operational range.

Understanding Mechanical Stress

Consider the physical demands on the packing. High shaft speeds generate significant frictional heat, while abrasive media like slurries can physically wear down the packing material. For abrasive conditions, a more robust variant like PTFE fiber packing is often necessary.

Verifying Equipment Compatibility

The packing must not only physically fit the stuffing box but also be materially compatible with the equipment components. This ensures there are no adverse reactions between the packing and the shaft or housing materials over time.

Understanding the Trade-offs

Choosing the right PTFE packing involves balancing performance requirements with practical and financial considerations.

Initial Cost vs. Total Cost of Ownership

PTFE packing often has a higher initial purchase price compared to other materials. However, its superior durability, reduced maintenance needs, and significantly longer service life frequently result in a lower total cost of ownership.

The Limits of Pure PTFE

While versatile, pure PTFE is not a universal solution. In high-speed applications, its poor thermal conductivity can lead to heat buildup. In such cases, a composite packing, like PTFE with graphite, is a better choice as graphite improves heat dissipation and lubricity.

Environmental Factors

You must also assess external environmental conditions. Exposure to excessive moisture, UV light, or abrasive dust can impact the longevity and performance of the packing seal, potentially requiring a more robust or specialized variant.

Making the Right Choice for Your Goal

Use your specific operational priority as the primary guide for your selection.

- If your primary focus is handling highly corrosive chemicals: Prioritize a packing with certified chemical compatibility for the specific media, such as pure PTFE, to prevent material degradation.

- If your primary focus is high-speed rotating equipment: Select a packing with excellent thermal conductivity and low friction, like a graphite-infused PTFE, to minimize heat buildup and shaft wear.

- If your primary focus is managing abrasive slurries: Choose a durable packing specifically engineered for abrasion resistance, such as PTFE fiber packing, to ensure a long service life.

- If your primary focus is compliance and purity: For food or pharmaceutical applications, ensure the packing meets all necessary FDA or other regulatory requirements.

By methodically matching these factors to your specific operational environment, you can ensure optimal performance, safety, and long-term value from your sealing solution.

Summary Table:

| Selection Factor | Key Consideration | Recommended PTFE Type |

|---|---|---|

| Chemical Compatibility | Resistance to specific acids, bases, solvents | Pure PTFE |

| Temperature & Pressure | Operating range to prevent degradation | Check manufacturer's specifications |

| Mechanical Stress | Shaft speed, presence of abrasive media | PTFE with graphite or fiber-reinforced |

| Equipment Fit | Physical dimensions and material compatibility | Ensure correct size and composition |

| Primary Goal | Corrosion resistance, high speed, abrasion, or purity | Tailor formulation to priority |

Ensure Long-Lasting, Reliable Sealing Performance

Selecting the right PTFE packing is critical to preventing equipment failure and costly downtime. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, packings, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution perfectly matched to your unique chemical, thermal, and mechanical requirements.

Let our experts help you optimize your sealing application. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key steps in the manufacturing process of PTFE coated fasteners? Build a Durable, Corrosion-Resistant Shield

- How does PTFE reduce friction wear in piping systems? Prevent Abrasive Damage and System Failure

- What are the main materials used in conventional oil seals and PTFE oil seals? Choose the Right Seal for Your Application

- How do PTFE-lined diaphragm valves contribute to cost savings? Reduce Operational Costs & Downtime

- What are the two common application methods for PTFE in slide bearings? A Guide to Linear and Rotational Movement

- What are the key advantages of using PTFE/Teflon tri-clamp sanitary gaskets? Maximize Purity & Performance

- Where are piston seals mainly used? Essential for Hydraulic & Pneumatic Systems

- What challenges do elastomeric seals face in oil and gas operations? Ensuring Reliability Under Extreme Conditions