Choosing the right PTFE packing requires a systematic evaluation of your application's specific demands. The primary factors you must consider are the operational conditions, including temperature, pressure, and chemical exposure, as well as the mechanical stresses the packing will endure and any necessary regulatory certifications.

The goal is not to find a universally "best" PTFE packing, but to precisely match the packing's material properties and construction to the unique environmental and mechanical demands of the equipment it will seal.

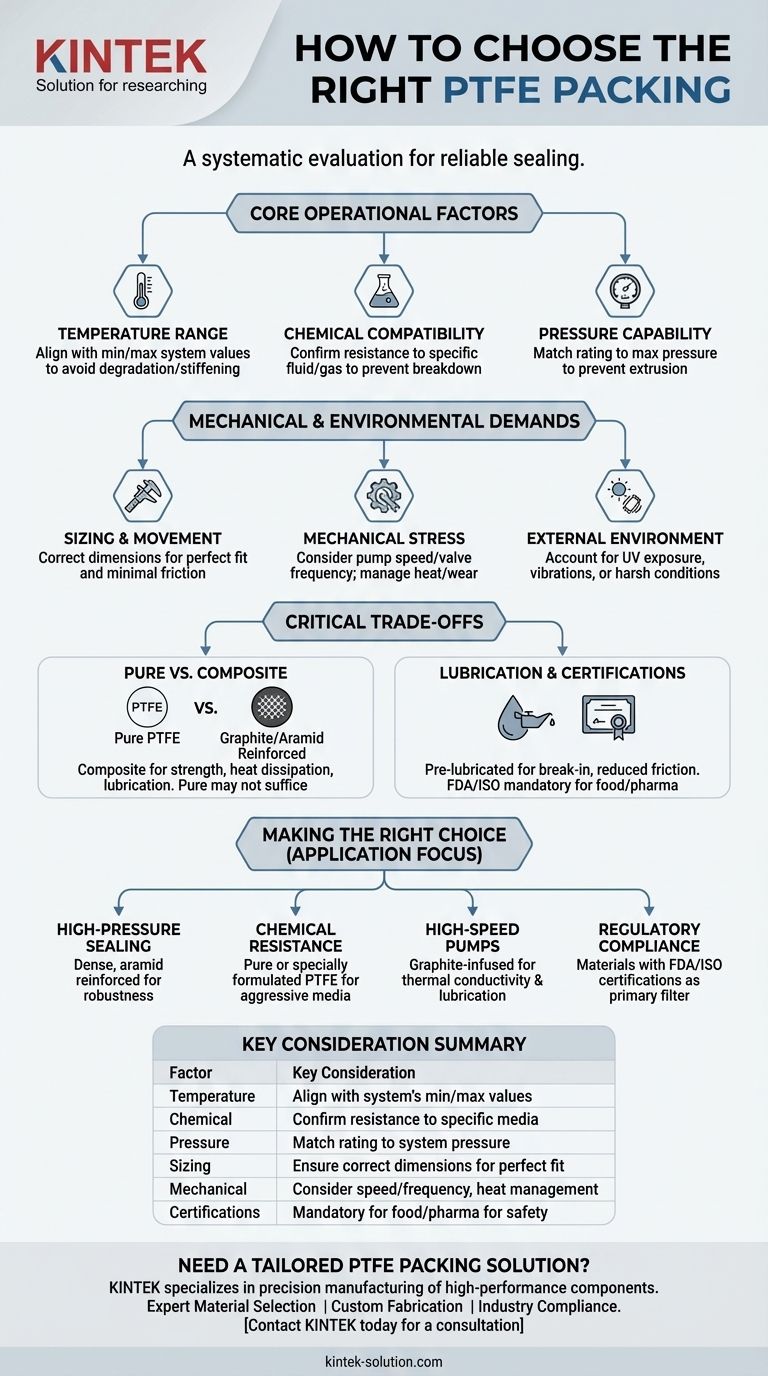

The Core Operational Factors

To ensure a durable and effective seal, you must begin by analyzing the fundamental conditions inside your system. These three factors dictate the baseline requirements for any packing material.

Temperature Range

PTFE has a distinct operational temperature range. Exceeding its upper limit can cause material degradation and a loss of sealing force, while operating at extremely low temperatures can reduce its flexibility. Always verify that the packing's specified service temperature aligns with your system's minimum and maximum operational values.

Chemical Compatibility

While PTFE is known for its exceptional resistance to most chemicals, it is not entirely inert. You must confirm that the packing material is compatible with the specific fluid or gas being sealed. This is critical for preventing material breakdown, contamination, and premature seal failure.

Pressure Handling Capability

Every packing is engineered to withstand a certain amount of pressure. System pressure exerts force on the packing, and using an underrated material can lead to extrusion, where the packing is forced into clearance gaps, causing a leak. Match the packing's pressure rating to the maximum expected pressure in your application.

Mechanical and Environmental Demands

Beyond the internal environment, the physical and external conditions play an equally important role in the packing's performance and longevity.

Sizing and Movement

Accurate sizing is non-negotiable. The packing's internal diameter, external diameter, and cross-section must be correct to fit the stuffing box perfectly. This ensures an effective seal without causing excessive friction or binding on moving components like pump shafts or valve stems.

Mechanical Stress

The dynamic nature of the application introduces mechanical stress. Consider factors like the rotational speed of a pump shaft or the actuation frequency of a valve. High-speed or high-frequency operations require packings designed to dissipate heat and resist wear.

External Environment

The environment outside the equipment can also affect the packing. Factors like prolonged UV exposure or significant vibrations can degrade certain packing materials over time. If your equipment operates in a harsh external environment, this must be a consideration in your selection.

Understanding Critical Trade-offs

Selecting a packing often involves balancing competing properties. Understanding these trade-offs is the mark of an informed decision.

Pure vs. Composite Materials

While "pure" PTFE packing exists, most high-performance packings are composites. They are often braided with other materials like graphite fibers to improve heat dissipation and lubrication, or aramid fibers at the corners to increase strength and prevent extrusion under high pressure. Pure PTFE may not be the optimal choice for demanding applications.

The Role of Lubrication

Many packings are pre-lubricated. This reduces friction during the critical break-in period, minimizes heat buildup on a pump shaft, and can extend the service life of both the packing and the equipment.

The Necessity of Certifications

For applications in the food, beverage, or pharmaceutical industries, certifications are mandatory. Procuring packings with the proper FDA or ISO certifications is essential for ensuring consumer safety and meeting regulatory compliance. This should be a primary filter in your selection process.

Making the Right Choice for Your Application

To select the ideal packing, align your choice with your primary operational challenge.

- If your primary focus is high-pressure sealing: Prioritize a dense, structurally robust packing, often reinforced with aramid or other high-strength fibers to prevent extrusion.

- If your primary focus is chemical resistance: Verify the packing's compatibility against your specific media and consider a pure or specially formulated PTFE variant for aggressive chemicals.

- If your primary focus is high-speed pumps: Select a packing with excellent thermal conductivity and lubrication, such as graphite-infused PTFE, to effectively manage frictional heat.

- If your primary focus is regulatory compliance: Your selection process must begin with materials that carry the necessary FDA or other relevant industry-specific certifications.

A methodical evaluation of these factors ensures a reliable seal, extends equipment life, and enhances operational safety.

Summary Table:

| Factor | Key Consideration |

|---|---|

| Temperature Range | Must align with system's min/max operational values to prevent degradation. |

| Chemical Compatibility | Confirm resistance to specific sealed fluid/gas to avoid breakdown. |

| Pressure Capability | Match packing's pressure rating to system pressure to prevent extrusion. |

| Sizing & Movement | Ensure correct dimensions for perfect fit and minimal friction. |

| Mechanical Stress | Consider speed/frequency; may require heat-dissipating materials. |

| Certifications | Mandatory for food/pharma (e.g., FDA, ISO) for safety and compliance. |

Need a PTFE Packing Solution Tailored to Your Specific Demands?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom packings, seals, and liners. We understand that the right seal is critical for reliability, safety, and efficiency in demanding applications.

We provide:

- Expert Material Selection: We help you navigate the trade-offs between pure PTFE and advanced composites (e.g., graphite or aramid-reinforced) to match your exact temperature, pressure, and chemical requirements.

- Custom Fabrication: From prototype development to high-volume production, we ensure perfect sizing and performance for your equipment.

- Industry Compliance: Our components are manufactured to meet stringent regulatory standards, including those for semiconductor, medical, and laboratory industries.

Let us help you enhance your equipment's performance and longevity. Contact KINTEK today for a consultation on your PTFE packing needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE spring energized seals preferred in the oil and gas industry? Unmatched Resilience for HPHT & Corrosive Environments

- What is a floating ball valve and how does it seal line pressure? A Guide to Pressure-Actuated Sealing

- What makes Teflon bushings suitable for harsh environments? Unmatched Chemical & Thermal Resistance

- How do PTFE O-rings perform against chemicals? Achieve Unmatched Chemical Resistance

- What industries commonly use Teflon CNC machined parts? Critical Solutions for Aerospace, Medical & More

- What are the main applications of PTFE lined valves? Control Corrosive & High-Purity Fluids

- How is PTFE utilized in the electrical and electronics industry? Unlock Superior Performance & Reliability

- What is a PTFE lined butterfly valve and how does it work? Control Corrosive & Pure Fluids Safely