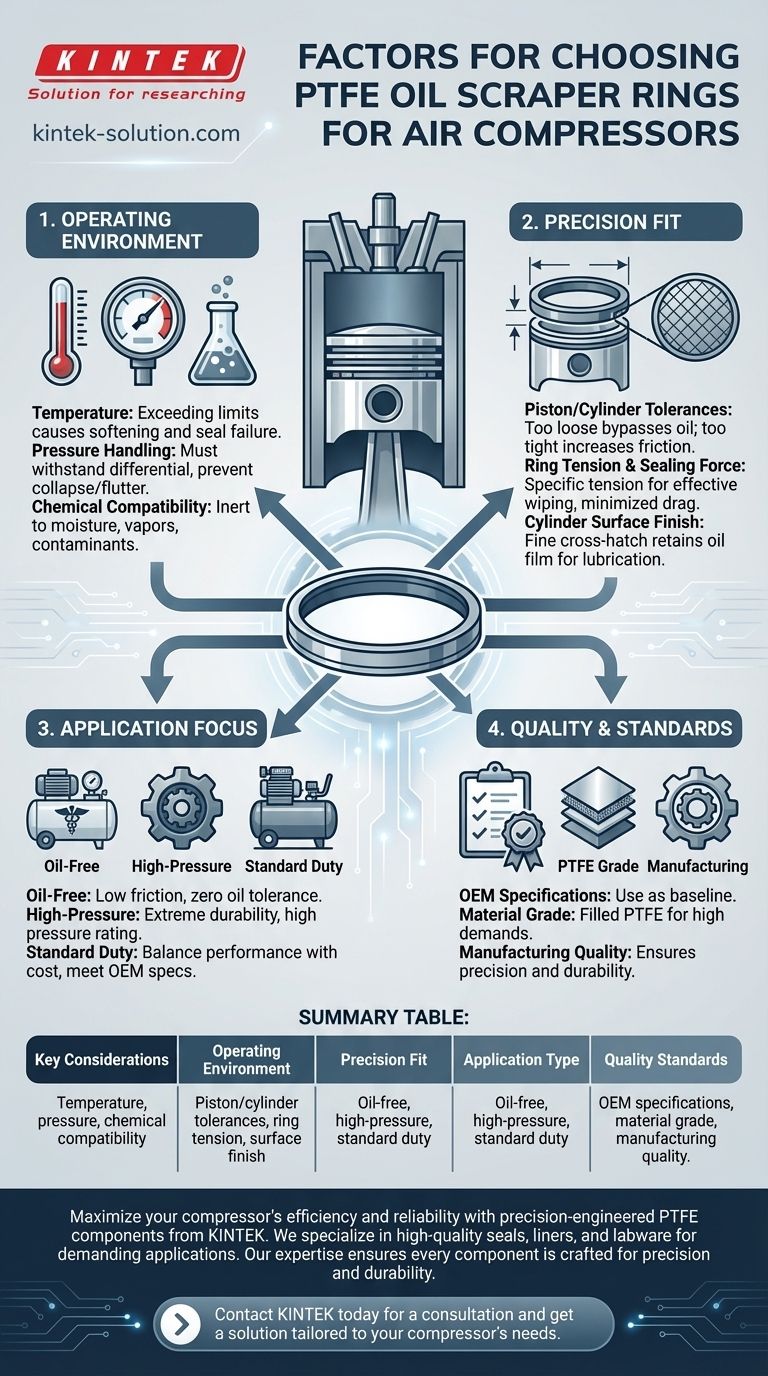

To select the right PTFE oil scraper ring, you must go beyond a simple part number and evaluate four critical factors. These include the compressor's specific operating conditions like temperature and pressure, the precise physical dimensions required for a proper seal, the compressor's application type (such as oil-free or high-pressure), and adherence to established quality and manufacturing standards.

The optimal PTFE ring is not just a component that fits; it is a precisely engineered seal that matches the unique thermal, pressure, and mechanical demands of your specific compressor system to ensure maximum efficiency and operational life.

Deconstructing the Operating Environment

The environment inside a compressor is harsh and dynamic. The PTFE ring's material composition and design must be chosen to survive and perform effectively within these specific conditions.

The Impact of Temperature

PTFE, while robust, has a defined operating temperature range. Exceeding this limit can cause the material to soften, lose its shape, and fail to maintain a seal, leading to increased oil consumption and blow-by. Always select a ring with a temperature rating that safely exceeds your compressor's maximum operating temperature.

Pressure Handling and Ring Design

The ring must withstand the full pressure differential within the cylinder on every stroke. High-pressure applications require rings with specific profiles and tension characteristics designed to prevent collapse or flutter, ensuring a consistent seal against the cylinder wall. A ring designed for low pressure will fail rapidly in a high-pressure system.

Chemical Compatibility

The "air" being compressed is rarely pure. It often contains moisture, oil vapors from upstream components, or other atmospheric contaminants. The PTFE compound must be chemically inert to these substances to prevent material degradation, swelling, or embrittlement over time.

Precision Fit: The Foundation of Sealing

A perfect seal is a game of micrometers. The physical relationship between the ring, piston, and cylinder wall is the single most important factor in its performance.

Piston and Cylinder Tolerances

The ring must fit perfectly in the piston groove and make precise contact with the cylinder wall. A ring that is too loose will allow oil to bypass the seal. A ring that is too tight will create excessive friction, leading to premature wear on both the ring and the cylinder liner.

Ring Tension and Sealing Force

An oil scraper ring works by exerting a specific, light pressure on the cylinder wall to wipe away excess oil. This inherent tension is engineered into the ring. Selecting a ring with the correct tension ensures effective oil control without causing unnecessary drag, which would reduce compressor efficiency and increase heat.

The Role of Cylinder Surface Finish

The ring and cylinder wall form a system. The cylinder's surface must have a specific finish—not perfectly smooth, but with a fine cross-hatch pattern. This pattern retains a microscopic film of oil for lubrication, allowing the PTFE ring to slide without generating excessive wear.

Understanding the Trade-offs and Pitfalls

Choosing the most expensive or highest-rated ring is not always the best strategy. A successful selection involves balancing performance with application reality and avoiding common mistakes.

Over-Specifying for the Application

Using a high-temperature or high-pressure ring in a standard-duty compressor is not an upgrade. These specialized rings can be stiffer and create more friction, potentially leading to lower efficiency and increased wear in an environment they were not designed for.

Ignoring the "Break-In" Period

New PTFE rings require a run-in period to conform perfectly to the cylinder wall. During this time, sealing performance may not be optimal. It is critical to follow the manufacturer's break-in procedure to ensure the ring "seats" correctly for a long service life.

Mismatching Ring Type to Compressor Duty

A ring intended for an oil-free medical air compressor is fundamentally different from one for a heavy industrial gas compressor. The former is designed for low friction and zero oil tolerance, while the latter is built for extreme durability and pressure. Using the wrong type will lead to rapid failure.

Making the Right Choice for Your Goal

Consult your compressor's Original Equipment Manufacturer (OEM) specifications first. When selecting a replacement, use those specifications as your baseline and adjust based on your primary objective.

- If your primary focus is maximum reliability in high-pressure systems: Prioritize rings made from high-grade, filled PTFE compounds and verify their pressure ratings match your system's peak demands.

- If your primary focus is maintaining oil-free air purity: Select rings specifically designated for "oil-free" operation, which are designed for minimal wear and material transfer.

- If your primary focus is cost-effective maintenance for standard duty: Ensure the ring meets all OEM dimensional and material specifications without over-investing in unnecessary high-performance features.

Choosing the right ring is an investment in the long-term health and efficiency of your entire compressor system.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Operating Environment | Temperature, pressure, chemical compatibility |

| Precision Fit | Piston/cylinder tolerances, ring tension, surface finish |

| Application Type | Oil-free, high-pressure, standard duty |

| Quality Standards | OEM specifications, material grade, manufacturing quality |

Maximize your compressor's efficiency and reliability with precision-engineered PTFE components from KINTEK.

We understand that the right oil scraper ring is critical for your system's performance. KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures every component is crafted for precision and durability, whether you need a custom prototype or a high-volume order. Let us help you select the perfect seal for your specific operating conditions and goals.

Contact KINTEK today for a consultation and get a solution tailored to your compressor's needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- Are Teflon sheets reusable? Maximize Their Lifespan for Cost-Effective Projects

- What types of fillers are commonly used in PTFE? Enhance Performance for Demanding Applications

- How do modern CNC machines contribute to energy efficiency in Teflon machining? Achieve Precision and Sustainability

- What are the differences between Teflon and rubber sealed bearings? Choose the Right Seal for Speed or Protection

- What are the advantages of Teflon washers? Achieve Superior Performance in Harsh Environments

- What are PTFE lined valves and what is their primary purpose? Achieve Superior Corrosion Resistance

- What are the challenges and recommendations for machining Teflon? Master Precision PTFE Fabrication

- How does carbon filler improve PTFE? Boost Strength, Wear & Thermal Performance