When choosing a grade of PTFE, you must evaluate it against your application's specific mechanical, thermal, and chemical demands. The primary factors to consider are the required mechanical strength, wear resistance, thermal conductivity, and coefficient of friction. Because pure PTFE is soft, manufacturers add various fillers to create specialized grades that enhance these properties for different uses.

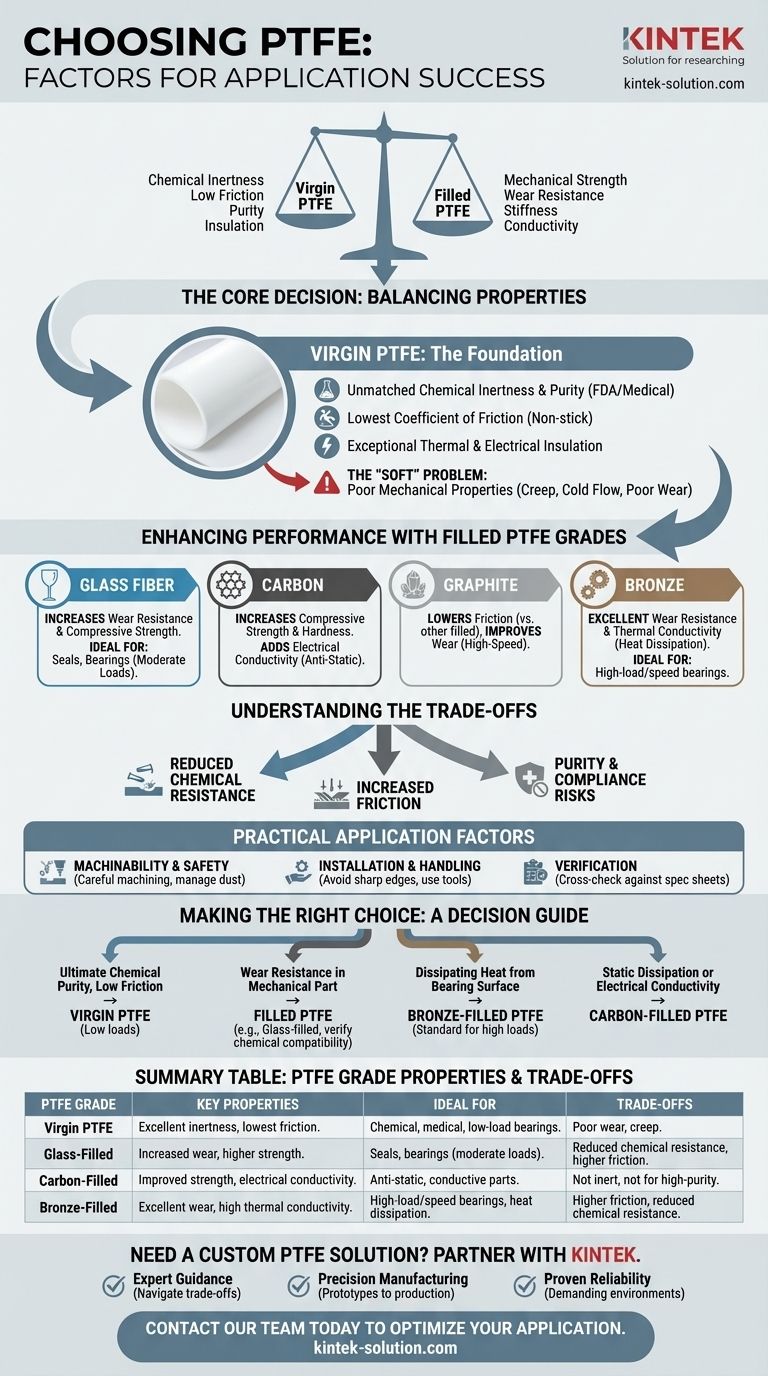

The core decision in selecting PTFE is not simply choosing the material, but choosing between pure (virgin) PTFE and a filled PTFE grade. Virgin PTFE offers the best chemical resistance and lowest friction, but filled grades are essential for any application requiring significant mechanical strength or wear resistance.

The Foundation: Understanding Virgin PTFE

Virgin, or unfilled, PTFE is a remarkable polymer with a unique combination of properties. Understanding its inherent strengths and weaknesses is the first step in making an informed selection.

Unmatched Chemical Inertness and Purity

Virgin PTFE is famously resistant to nearly all industrial chemicals and solvents. This makes it the default choice for seals, linings, and components in harsh chemical processing environments.

Because it is exceptionally pure and contains no additives, it is often FDA-approved for food contact and suitable for many medical and pharmaceutical applications.

The Lowest Coefficient of Friction

Known as one of the most slippery materials in existence, virgin PTFE has an extremely low coefficient of friction. This property is invaluable for creating low-friction bearings, slide plates, and non-stick surfaces.

Exceptional Thermal and Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength and a very high melting point (up to 500°F / 260°C). It also resists ignition and does not promote flame spread, carrying a UL94 V-0 rating.

The "Soft" Problem: Poor Mechanical Properties

The primary weakness of virgin PTFE is its mechanical performance. It is a relatively soft material that can deform under load, a phenomenon known as creep or cold flow. It also has poor wear resistance when subjected to friction from other components.

Enhancing Performance with Filled PTFE Grades

To overcome the mechanical limitations of virgin PTFE, manufacturers add reinforcing fillers. The choice of filler is entirely dependent on the specific performance boost required by the application.

Why Add Fillers?

Fillers are added to PTFE to dramatically improve properties like compressive strength, stiffness, and wear resistance. They can also be used to modify thermal and electrical conductivity.

Common Filler: Glass Fiber

Glass is one of the most common fillers. It significantly increases wear resistance and compressive strength, making it ideal for seals and bearings that experience moderate mechanical loads.

Common Filler: Carbon

Adding carbon increases compressive strength and hardness. Critically, it also transforms PTFE from an electrical insulator into an electrical conductor, making it suitable for anti-static applications.

Common Filler: Graphite

Graphite is often added, sometimes in combination with carbon, to lower the coefficient of friction compared to other filled grades and improve wear characteristics in high-speed applications.

Common Filler: Bronze

Bronze fillers provide excellent wear resistance and a significantly higher thermal conductivity than other grades. This allows heat to be drawn away from a bearing surface, making it suitable for mechanical applications with high loads and speeds.

Understanding the Trade-offs

Selecting a filled PTFE is an exercise in balancing competing properties. Enhancing one characteristic almost always comes at the expense of another.

The Filler Compromise: Reduced Chemical Resistance

While virgin PTFE is nearly inert, the fillers themselves are not. A glass-filled PTFE, for example, would be a poor choice for handling hydrofluoric acid or strong alkalis, as these chemicals will attack the glass filler.

The Friction Factor: Fillers Increase Friction

No filled grade is as slippery as virgin PTFE. Adding any solid particle will inherently increase the coefficient of friction, though it often remains very low compared to other plastics.

Purity and Compliance

The addition of fillers means the material may no longer meet FDA or other purity standards required for food, medical, or pharmaceutical use.

Practical Application Factors

Beyond material composition, you must consider the practical realities of fabrication and installation.

Machinability and Safety

PTFE's softness and low melting point require care during machining. Use extremely sharp, high-speed steel drills to prevent melting and material deformation.

When machining any PTFE, the fine dust produced can be hazardous if inhaled. Always work under a coolant system or wear appropriate respiratory protection.

Installation and Handling

The material's softness makes it prone to damage. When installing PTFE O-rings or seals, you must avoid stretching them over sharp threads or corners, which can cause nicks or gouges that lead to seal failure. Use corner breaks or specialized installation tools.

Verification is Non-Negotiable

Always verify your chosen material's performance against the manufacturer's official specification sheet. Any technical data is for informational purposes only and must be cross-checked for suitability in your specific operating environment.

Making the Right Choice for Your Application

Use your primary goal to guide your initial selection, then verify it against all other application requirements.

- If your primary focus is ultimate chemical purity and low friction: Virgin PTFE is the correct choice, provided mechanical loads are low.

- If your primary focus is wear resistance in a mechanical part: A filled PTFE (like glass-filled) is necessary, but you must verify its chemical compatibility with your environment.

- If your primary focus is dissipating heat from a bearing surface: A bronze-filled PTFE is the standard choice due to its superior thermal conductivity.

- If your primary focus is static dissipation or electrical conductivity: A carbon-filled PTFE is designed specifically for this purpose.

By balancing the exceptional properties of virgin PTFE with the targeted enhancements of filled grades, you can select the precise material to ensure your project's success.

Summary Table:

| PTFE Grade | Key Properties | Ideal For | Trade-offs |

|---|---|---|---|

| Virgin PTFE | Excellent chemical inertness, lowest friction, high purity | Chemical processing, medical, food contact, low-load bearings | Poor wear resistance, prone to creep/cold flow |

| Glass-Filled PTFE | Increased wear resistance, higher compressive strength | Seals, bearings under moderate mechanical loads | Reduced chemical resistance, higher friction than virgin |

| Carbon-Filled PTFE | Improved compressive strength, electrical conductivity | Anti-static applications, mechanical parts needing conductivity | Not chemically inert, not for high-purity uses |

| Bronze-Filled PTFE | Excellent wear resistance, high thermal conductivity | High-load, high-speed bearings, heat dissipation applications | Higher friction, reduced chemical resistance |

Need a Custom PTFE Solution for Your Critical Application?

Selecting the right PTFE grade is crucial for the performance and longevity of your components. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Why partner with KINTEK?

- Expert Guidance: Our material scientists help you navigate the trade-offs between virgin and filled PTFE grades to match your specific mechanical, thermal, and chemical requirements.

- Precision Manufacturing: We ensure every component meets exact specifications, from prototypes to high-volume production runs.

- Proven Reliability: Our PTFE parts are trusted in demanding environments where chemical resistance, low friction, or enhanced wear resistance is non-negotiable.

Let us help you optimize your application. Contact our team today to discuss your project requirements and receive a tailored solution that delivers superior performance and value.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How was the slipperiness of Teflon studied in the research? Visualizing Material Transfer at the Molecular Level

- Why is PTFE considered an ideal substitute for other plastics in high-temperature applications? Superior Thermal Stability & Performance

- How is PTFE used in industrial applications? Solve Extreme Chemical, Thermal & Friction Challenges

- How is Teflon used in the chemical industry? Protect Equipment and Ensure Purity

- What automotive application benefits from PTFE coating? Enhance Vehicle Reliability and Performance

- How do Nylon and PTFE compare in terms of durability and strength? Choosing the Right Polymer for Your Application

- Why is Teflon a good electrical insulator? Unmatched Performance for Demanding Applications

- Why is PTFE's chemical inertness important for aerospace applications? Ensuring Safety & Reliability in Demanding Environments