The choice between PTFE and traditional bushings is a critical engineering decision that hinges on four primary factors: the mechanical load, the operating environment, maintenance requirements, and overall cost. PTFE excels in applications requiring low friction and resistance to corrosion or high temperatures, while traditional bushings are often the go-to for high-load scenarios or when initial cost is the dominant concern.

The core of this decision is not about which bushing is universally "better," but which material's distinct properties are precisely matched to the demands of your specific application. The goal is to align the component's strengths with the operational challenges it will face.

The Core Strengths of PTFE Bushings

Polytetrafluoroethylene (PTFE) is a high-performance polymer with a unique combination of properties. Understanding these strengths is key to knowing when to specify it.

Unmatched Low-Friction Performance

PTFE possesses an extremely low coefficient of friction. This property is inherent to the material itself, meaning it doesn't rely on external lubricants.

This results in self-lubricating performance, which ensures smooth, consistent movement and quiet operation, making it ideal for applications where stick-slip motion must be avoided.

Superior Environmental Resistance

PTFE is virtually inert to most chemicals, making it exceptionally resistant to corrosion. It is also unaffected by moisture.

Furthermore, it can operate effectively across a wide range of temperatures where traditional materials might degrade or fail.

The Value of Zero-Maintenance Operation

Because they are self-lubricating, PTFE bushings eliminate the need for regular greasing or oiling.

This "set and forget" quality drastically reduces maintenance schedules and costs, which is a significant advantage in hard-to-reach or critical applications where downtime is unacceptable.

When Traditional Bushings Excel

While PTFE offers specialized benefits, traditional bushings, often made of bronze, steel, or other plastics, remain the standard for many common applications for good reason.

Handling High-Load Applications

The primary advantage of many traditional metal bushings is their superior load capacity.

For machinery and equipment subjected to heavy forces and high pressures, a metallic bushing often provides the structural integrity and resistance to deformation that PTFE cannot.

Managing Initial Project Costs

In cost-sensitive projects, traditional bushings typically have a lower upfront purchase price.

When the operating environment is mild and regular lubrication is not a problem, their lower initial cost makes them a practical and economical choice.

Understanding the Trade-offs

A truly optimal choice requires an objective look at the compromises inherent in each option. The best decision is rarely based on a single factor.

Initial Cost vs. Total Cost of Ownership

PTFE bushings are generally more expensive to purchase.

However, their higher initial cost can be offset over the component's lifetime by eliminating the expense of lubricants, labor for maintenance, and potential downtime.

Load Capacity as a Defining Limit

The most significant limitation of PTFE is its relatively low compressive strength compared to metal.

Placing a PTFE bushing in an application with loads exceeding its capacity will lead to premature failure. You must always verify that the load requirements fall within the material's specifications.

Lubrication as a Design Strategy

Traditional bushings require a lubrication strategy. This adds complexity to the design and a recurring task to the maintenance schedule.

PTFE's self-lubricating nature simplifies design and eliminates this maintenance burden entirely, making it a more robust solution for systems intended to operate autonomously.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important priority for your design.

- If your primary focus is smooth, maintenance-free operation in a corrosive or high-temperature environment: PTFE is the superior choice due to its inherent material properties.

- If your primary focus is supporting heavy static or dynamic loads: A traditional metal bushing provides the necessary strength and durability.

- If your primary focus is minimizing the initial component cost for a standard application: Traditional bushings offer a clear and immediate financial advantage.

- If your primary focus is quiet operation, electrical insulation, or moisture resistance: PTFE's unique characteristics are specifically suited to meet these needs.

By carefully weighing these factors against your application's demands, you can select the component that ensures optimal performance and long-term reliability.

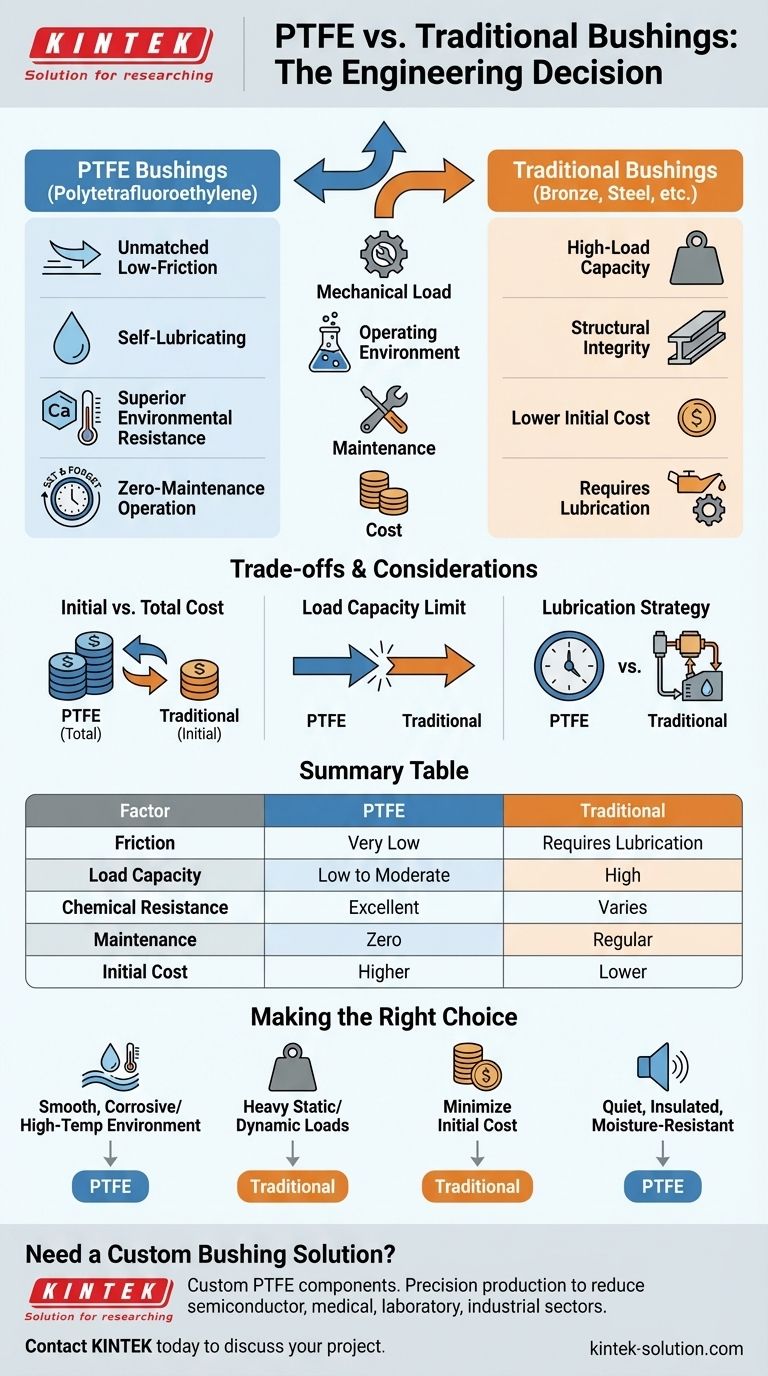

Summary Table:

| Factor | PTFE Bushings | Traditional Bushings |

|---|---|---|

| Friction | Very Low (Self-Lubricating) | Requires Lubrication |

| Load Capacity | Low to Moderate | High |

| Chemical Resistance | Excellent | Varies (Often Lower) |

| Maintenance | Zero Maintenance | Regular Lubrication Needed |

| Initial Cost | Higher | Lower |

Need a Custom Bushing Solution?

KINTEK specializes in manufacturing high-performance PTFE components, including custom bushings, seals, and liners. Whether your priority is zero-maintenance operation, chemical resistance, or a specific design for demanding environments in the semiconductor, medical, laboratory, or industrial sectors, we can help.

We combine precision production with custom fabrication expertise, from prototypes to high-volume orders, to deliver a component perfectly matched to your application's requirements.

Contact KINTEK today to discuss your project and get a quote for a bushing solution that ensures optimal performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support