The choice between PTFE and silicone septa hinges on a single question: What level of chemical resistance does your specific application demand? For applications involving aggressive solvents or requiring maximum sample integrity, PTFE is the superior choice due to its chemical inertness and temperature stability. For more routine procedures with less reactive chemicals, silicone provides a flexible and highly cost-effective solution.

This decision is not about which material is universally "better," but which one is appropriate for your specific analytical conditions. The goal is to match the septa's properties to your solvent, temperature, and re-sealing requirements to ensure data integrity without unnecessary cost.

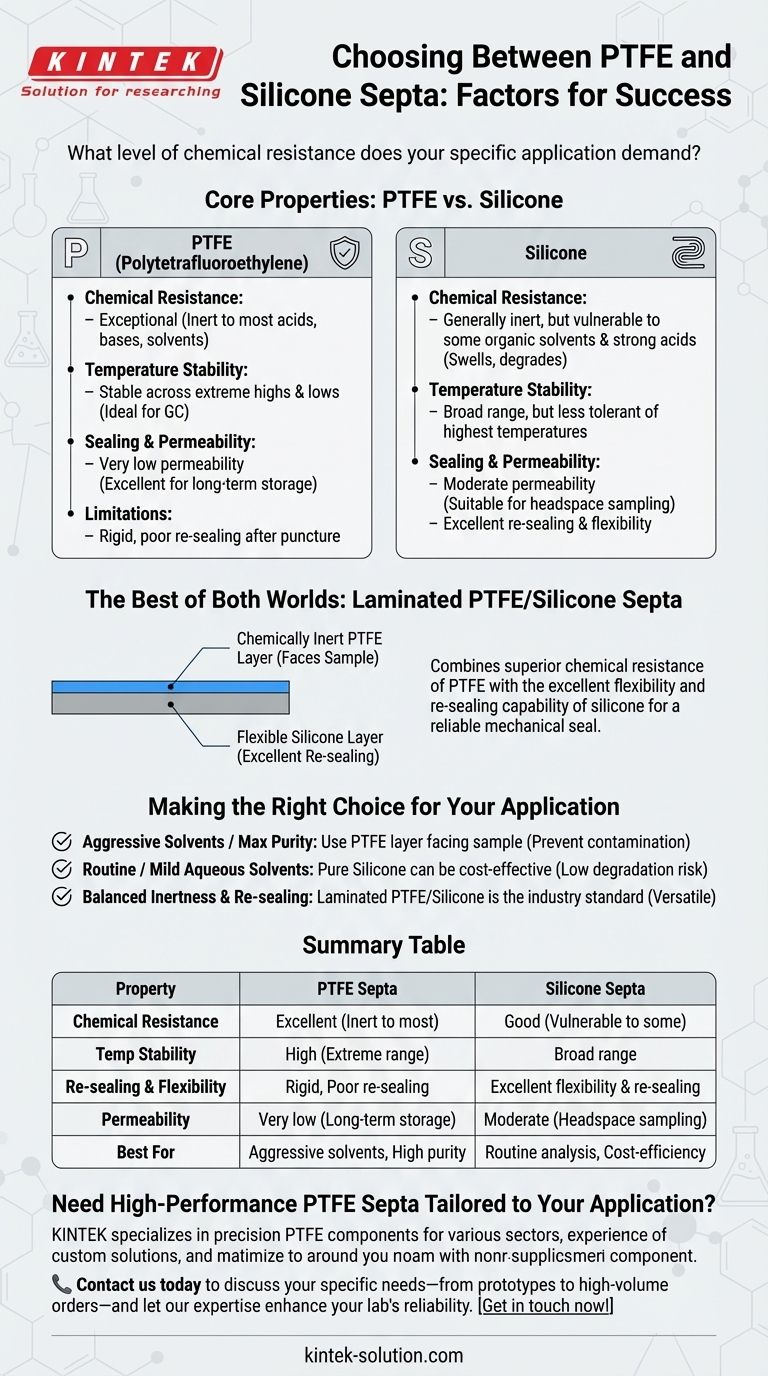

Core Properties: PTFE vs. Silicone

The functional differences between these materials are rooted in their distinct chemical and physical properties. Understanding these is key to making the correct choice.

Chemical Resistance: The Deciding Factor

PTFE (Polytetrafluoroethylene) offers exceptional chemical resistance. It is virtually inert against the vast majority of acids, bases, and organic solvents, making it the default choice for protecting samples from contamination or reaction.

Silicone is generally inert but has known vulnerabilities. It can swell, degrade, or leach extractables when exposed to certain organic solvents or strong acids, which can compromise sample integrity and produce unreliable results.

Temperature Stability: Handling the Extremes

PTFE is stable across a very wide temperature range, withstanding both extreme highs and lows. This makes it highly suitable for applications in gas chromatography (GC) or other processes involving significant temperature fluctuations.

Silicone also performs well across a broad temperature range and provides excellent flexibility. However, it may not handle the highest operational temperatures as effectively as PTFE.

Sealing and Permeability: Protecting Your Sample

PTFE has very low permeability. This property creates a highly effective barrier against gases and prevents solvent evaporation, which is critical for long-term sample storage and maintaining sample concentration.

Silicone has moderate permeability. While this is a disadvantage for long-term storage, it can be suitable for applications like headspace sampling where some gas exchange is tolerable. Its primary physical advantage is its flexibility and excellent re-sealing capability after puncture.

Understanding the Trade-offs and Hybrid Solutions

Choosing a septum is rarely about a single property; it's about balancing performance, cost, and physical handling. This is why hybrid septa are so common.

The Limitation of Single Materials

A pure PTFE septum, while chemically inert, can be rigid. This can lead to poor re-sealing after being punctured by a needle, potentially causing sample evaporation or contamination on subsequent injections.

A pure silicone septum provides excellent re-sealing but poses a direct risk of chemical interaction with the sample. The needle pushes through the silicone, creating a pathway for potential contamination.

The Best of Both Worlds: Laminated PTFE/Silicone Septa

The most common solution in modern labs is the laminated PTFE/Silicone septum. This design combines a thin layer of chemically inert PTFE that faces the sample with a thicker, more flexible layer of silicone.

This hybrid approach provides the superior chemical resistance of PTFE where it matters most—in direct contact with the sample—while leveraging the excellent flexibility and re-sealing capability of silicone for a reliable mechanical seal.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your analytical method.

- If your primary focus is aggressive solvents or maximum sample purity: You must use a septum with a PTFE layer facing the sample to prevent chemical interaction and contamination.

- If your primary focus is routine, high-volume analysis with mild aqueous solvents: Pure silicone can be a highly cost-effective option where the risk of chemical degradation is negligible.

- If your primary focus is balancing chemical inertness with reliable re-sealing for multiple injections: A laminated PTFE/Silicone septum is the industry standard and the most versatile choice.

Ultimately, selecting the correct septum is a foundational step in ensuring the accuracy and reproducibility of your analytical results.

Summary Table:

| Property | PTFE Septa | Silicone Septa |

|---|---|---|

| Chemical Resistance | Excellent (inert to most acids, bases, solvents) | Good, but swells/degrades with some solvents |

| Temperature Stability | High (stable across extreme temperatures) | Broad range, but may not handle the highest temps |

| Re-sealing & Flexibility | Rigid, poor re-sealing after puncture | Excellent flexibility and re-sealing capability |

| Permeability | Very low (ideal for long-term storage) | Moderate (suited for headspace sampling) |

| Best For | Aggressive solvents, high-purity applications | Routine analysis with mild solvents, cost-efficiency |

Need High-Performance PTFE Septa Tailored to Your Application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require chemically inert PTFE septa for aggressive solvents or custom laminated PTFE/silicone hybrids for optimal sealing, we deliver solutions that ensure sample integrity and data accuracy.

📞 Contact us today to discuss your specific needs—from prototypes to high-volume orders—and let our expertise enhance your lab's reliability. Get in touch now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application