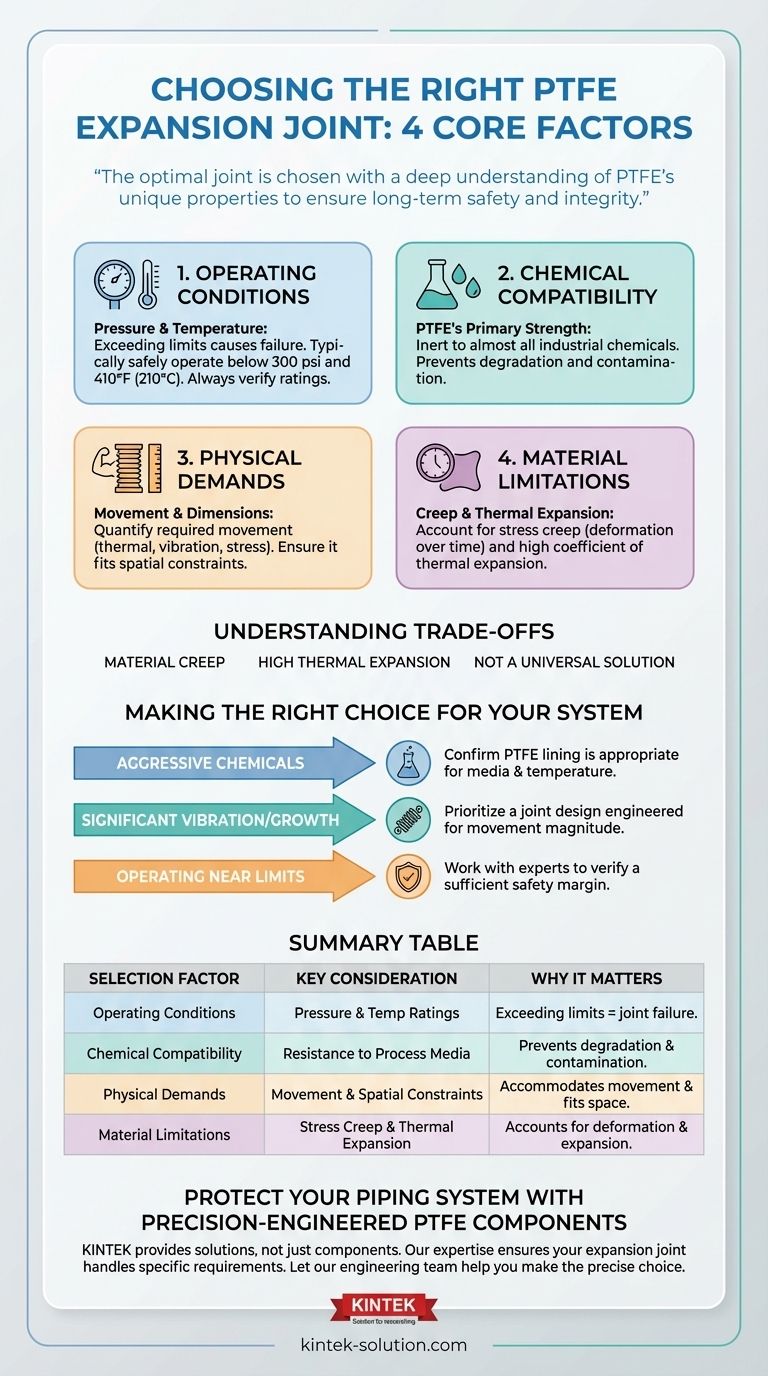

When choosing a PTFE expansion joint, you must evaluate four primary factors. These are the system's operating pressure and temperature, the chemical compatibility of the media flowing through it, the degree of physical movement required, and the available space for installation.

The optimal PTFE expansion joint is not just one that meets a list of specifications. It is a component chosen with a deep understanding of PTFE's unique material properties—its incredible chemical resistance balanced against its physical limitations—to ensure the long-term safety and integrity of the entire piping system.

Deconstructing the Core Selection Criteria

To select the right component, you must analyze its operational environment from multiple angles. The correct joint is one where the material's strengths are maximized and its inherent weaknesses are accounted for by the design.

Operating Conditions: Pressure and Temperature

The pressure and temperature ratings of a PTFE expansion joint are critically important and interdependent. Exceeding these limits can lead to premature failure.

PTFE is highly stable, but it has boundaries. Many applications operate safely below 300 psi and 410°F (210°C), but you must always verify the specific rating for the joint you are considering.

Chemical Compatibility: PTFE's Primary Strength

PTFE's defining characteristic is its tremendous chemical resistance. It is inert to almost all industrial chemicals, making it the default choice for systems handling corrosive or aggressive media.

This property ensures that the expansion joint will not degrade, contaminate the process media, or become a point of failure due to chemical attack.

Physical Demands: Movement and Dimensions

Expansion joints exist to absorb movement. You must quantify the extent of movement the joint needs to accommodate, whether from thermal expansion, vibration, or system stress.

The physical dimensions and design of the joint are also crucial, especially in retrofits or systems with tight spatial constraints. An improperly sized joint cannot perform its function correctly.

Understanding the Trade-offs and Limitations

While PTFE is a remarkable material, it is not without its limitations. Acknowledging these trade-offs is essential for making an informed decision and preventing system failures.

Material Creep

Under sustained pressure and temperature, PTFE can exhibit stress creep, a tendency to slowly and permanently deform over time. A well-designed joint from a reputable supplier will account for this property to ensure a long service life.

High Thermal Expansion

Ironically, while the joint accommodates thermal expansion in the piping, PTFE itself has a high coefficient of thermal expansion. The manufacturer must manage this property in the joint's design to maintain dimensional accuracy across the operating temperature range.

Not a Universal Solution

Despite its versatility, PTFE is not always the answer. For systems operating at extremely high pressures or temperatures beyond PTFE's capabilities, alternative materials like metal may be required.

Making the Right Choice for Your System

Partnering with a knowledgeable supplier who can provide engineering and design support is often the best path to ensuring safety and longevity. Use your specific goals to guide your final selection.

- If your primary focus is handling aggressive chemicals: Confirm the joint's PTFE lining is appropriate for the specific media, temperature, and concentration.

- If your primary focus is absorbing significant vibration or thermal growth: Prioritize a joint design specifically engineered for the type and magnitude of movement your system will experience.

- If your primary focus is operating near known pressure or temperature limits: Work directly with a technical expert to verify that the selected joint has a sufficient safety margin for your specific conditions.

Ultimately, selecting the right PTFE expansion joint is about making a precise engineering choice that protects your entire system.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Operating Conditions | Pressure & Temperature Ratings | Exceeding limits can cause joint failure. Standard limits are typically <300 psi and <410°F (210°C). |

| Chemical Compatibility | Resistance to Process Media | PTFE is inert to most chemicals, preventing degradation and contamination. |

| Physical Demands | Movement & Spatial Constraints | The joint must accommodate thermal expansion, vibration, and fit in the available space. |

| Material Limitations | Stress Creep & Thermal Expansion | A quality design accounts for PTFE's tendency to deform under stress and expand with heat. |

Protect Your Piping System with Precision-Engineered PTFE Components

Choosing the right PTFE expansion joint is a critical engineering decision that impacts the safety and integrity of your entire operation. At KINTEK, we don't just sell components; we provide solutions.

We specialize in manufacturing high-performance PTFE components—including seals, liners, labware, and custom expansion joints—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your expansion joint is designed to handle your specific pressure, temperature, chemical, and movement requirements, accounting for PTFE's unique properties to maximize service life.

Let our engineering team help you make the precise choice. From prototypes to high-volume orders, we deliver the quality and reliability your system demands.

Contact KINTEK today for expert guidance and a custom solution tailored to your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How is PTFE used in the medical device industry? Enhancing Safety and Performance in Medical Devices

- In what types of environments are expanded PTFE gaskets particularly effective? Sealing Harsh Chemical & Imperfect Flanges

- What industries commonly use Teflon washers? Unlock Versatile Sealing Solutions

- What chemical resistance properties does PTFE offer? Master Its Inertness for Demanding Applications

- What industries commonly use PTFE components? Critical Solutions for Extreme Environments

- What are the limitations of PTFE gaskets in high-pressure applications? Overcoming Cold Flow & Creep Issues

- What are the advantages of PTFE diaphragms? Achieve Unmatched Chemical & Thermal Resistance

- How can leaking in a PTFE butterfly valve be fixed? A Guide to Reliable Sealing Solutions