In essence, the durability of PTFE O-rings stems from a unique combination of extreme chemical inertness, a wide operating temperature range, and excellent resistance to physical degradation. These properties are a direct result of the strong carbon-fluorine bonds that make up the material's molecular structure, rendering it stable in some of the most demanding industrial environments.

While PTFE's chemical and thermal resilience is nearly unmatched, its durability is best understood as a trade-off. Its characteristic rigidity and low elasticity make it a specialist material, excelling in static, high-exposure environments but requiring careful design considerations for dynamic or low-temperature sealing.

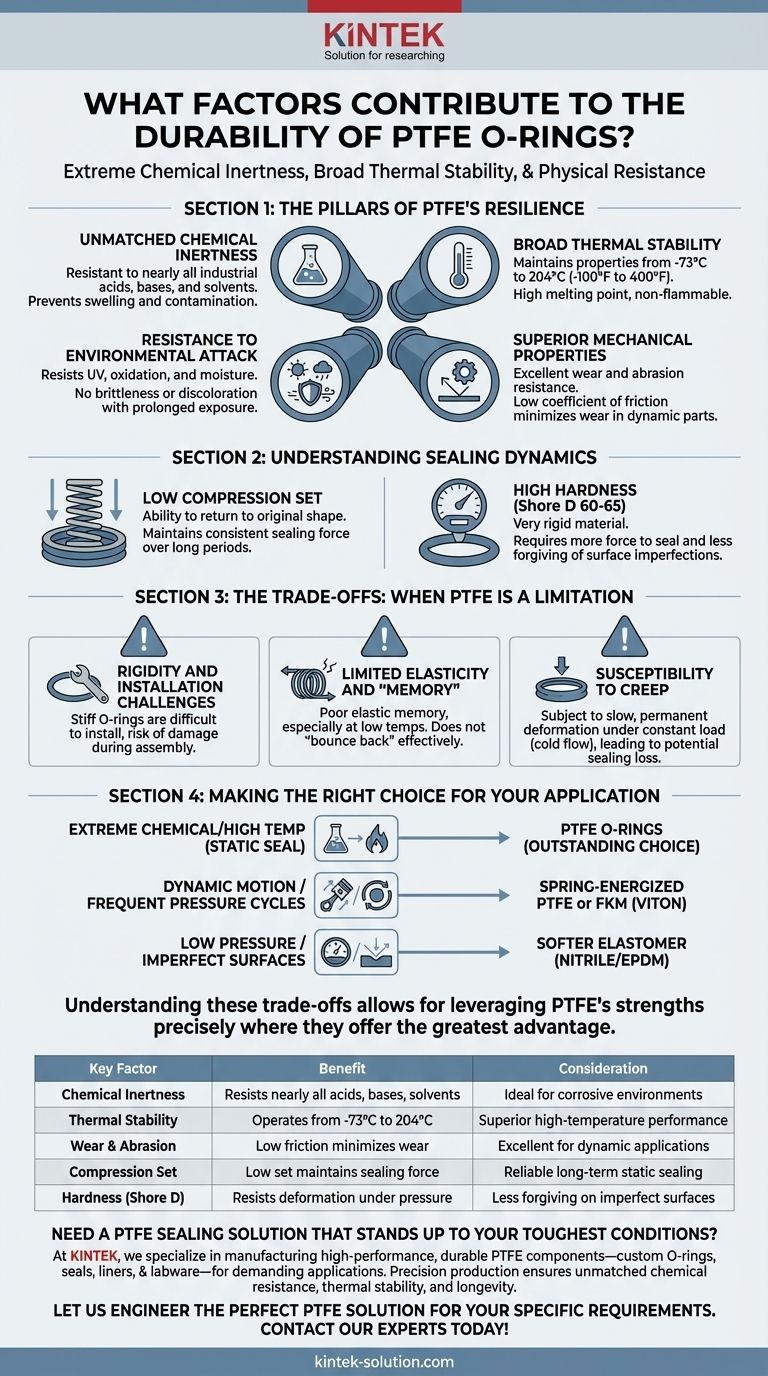

The Pillars of PTFE's Resilience

The remarkable durability of Polytetrafluoroethylene (PTFE) is not based on a single attribute but on the synergy of several core properties. Understanding each one is key to knowing when and how to deploy these seals effectively.

Unmatched Chemical Inertness

PTFE is famous for being resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents.

This inertness prevents the O-ring from swelling, softening, or degrading when exposed to corrosive fluids, ensuring the integrity of the seal and preventing contamination of the system media.

Broad Thermal Stability

PTFE O-rings maintain their properties across a very wide temperature range, typically from -73°C to 204°C (-100°F to 400°F).

It has a high melting point and is non-flammable, meaning it will not deform or break down in high-heat applications where other elastomers would fail.

Resistance to Environmental Attack

The material is highly resistant to weathering factors such as UV radiation, oxidation, and moisture.

Unlike many plastics and rubbers, PTFE does not become brittle, discolor, or degrade with prolonged outdoor exposure, making it suitable for long-term applications. Its low water absorption ensures dimensional stability.

Superior Mechanical Properties

PTFE exhibits excellent resistance to wear and abrasion, supported by a very low coefficient of friction.

This slippery surface minimizes wear in dynamic applications with moving parts. While it has good tensile strength, its primary mechanical advantage in sealing is its ability to resist degradation from friction.

Understanding Sealing Dynamics

An O-ring's material properties directly influence its ability to create and maintain a seal under pressure. For PTFE, its hardness and compression characteristics are defining factors.

The Role of Compression Set

Compression set refers to a material's ability to return to its original shape after a compressive force is removed.

PTFE has a low compression set, which is a highly desirable trait. It means the O-ring will continue to push back against the sealing surfaces, maintaining a consistent sealing force over long periods.

The Impact of Hardness

PTFE is a very rigid material, with a hardness typically around 60-65 on the Shore D scale. For comparison, most common rubber O-rings are measured on the softer Shore A scale.

This hardness means PTFE O-rings are not easily compressed. They require more force to create an initial seal and are less forgiving of imperfections on the sealing surfaces than a softer, more pliable rubber O-ring.

The Trade-offs: When PTFE Is a Limitation

No material is perfect for every situation. The very properties that make PTFE durable also create specific limitations that are critical to understand.

Rigidity and Installation Challenges

The stiffness of solid PTFE O-rings can make them difficult to install, especially when stretching them into a groove. Care must be taken to avoid scratching or permanently deforming the ring during assembly.

Limited Elasticity and "Memory"

Unlike true elastomers, PTFE has poor elastic memory, particularly at lower temperatures. It doesn't "bounce back" as effectively after compression.

This makes it less suitable for applications with frequent pressure cycles or significant thermal expansion and contraction, as it may not adapt quickly enough to maintain a perfect seal.

Susceptibility to Creep

Under a constant compressive load, PTFE can be subject to creep, or "cold flow." This is a slow, permanent deformation of the material.

Over time, creep can lead to a loss of sealing force, potentially causing a leak in long-term, high-pressure static applications. This is why spring-energized PTFE seals are often used to counteract this effect.

Making the Right Choice for Your Application

Selecting the correct O-ring material requires matching its properties to the demands of your specific environment and function.

- If your primary focus is extreme chemical or high-temperature resistance in a static seal: PTFE is an outstanding choice due to its unparalleled inertness and thermal stability.

- If your application involves dynamic motion or frequent pressure cycles: Consider a spring-energized PTFE seal or a more elastic fluoroelastomer like FKM (Viton) for better resilience.

- If you need a seal for a low-pressure application with imperfect surfaces: A softer elastomer O-ring, such as Nitrile (Buna-N) or EPDM, will likely provide a more reliable and forgiving seal than rigid PTFE.

Understanding these fundamental trade-offs allows you to leverage PTFE's exceptional strengths precisely where they offer the greatest advantage.

Summary Table:

| Key Factor | Benefit | Consideration |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents | Ideal for corrosive environments |

| Thermal Stability | Operates from -73°C to 204°C (-100°F to 400°F) | Superior high-temperature performance |

| Wear & Abrasion Resistance | Low coefficient of friction minimizes wear | Excellent for dynamic applications |

| Compression Set | Low compression set maintains sealing force | Reliable long-term static sealing |

| Hardness (Shore D 60-65) | Resists deformation under pressure | Less forgiving on imperfect surfaces |

Need a PTFE sealing solution that stands up to your toughest conditions?

At KINTEK, we specialize in manufacturing high-performance, durable PTFE components—including custom O-rings, seals, liners, and labware—for the most demanding semiconductor, medical, laboratory, and industrial applications. Our precision production and custom fabrication services ensure you get a seal that delivers unmatched chemical resistance, thermal stability, and longevity, whether you need prototypes or high-volume orders.

Let us engineer the perfect PTFE solution for your specific requirements. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the applications of PTFE in the chemical industry? A Guide to Superior Corrosion Resistance

- What are the key advantages of PTFE rotary shaft lip seals in high-pressure applications? Achieve Superior Sealing Performance

- In what types of applications is EPDM more effective than PTFE for wafer style butterfly valves? Optimize for Water & Steam Systems

- What are the recommended cutting parameters for machining PTFE? Achieve Precision with the Right Speed, Feed, and Depth of Cut

- What lip style options are available for high-pressure PTFE seals? Choose the Right Seal for Extreme Conditions

- How does the high temperature resistance of PTFE processing machines benefit their operation? Ensuring Reliable, High-Quality Production

- In what forms are Metal-Polymer Bronze Backed PTFE Plain Bearings available? Choose the Right Form for Your Load

- What are the practical advantages of ePTFE gaskets in installation? Simplify Sealing with On-Site Fabrication