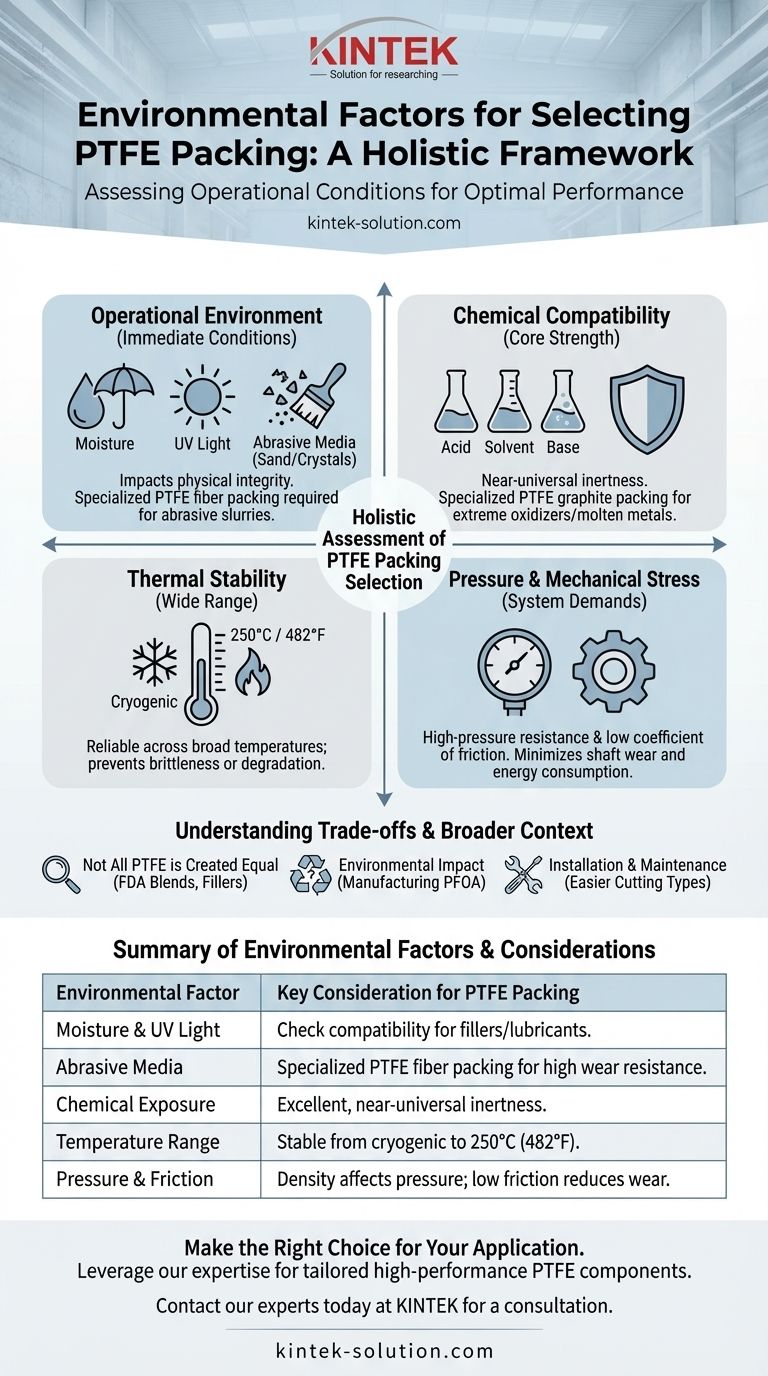

When selecting PTFE packing, the key environmental factors to assess are exposure to moisture, UV light, and the presence of abrasive materials. These elements directly impact the packing's physical integrity and lifespan. For instance, applications involving slurries or other particulates often demand specialized variants, like PTFE fiber packing, specifically designed to withstand abrasive wear.

The core challenge is not just identifying environmental factors, but understanding them as part of a larger operational system. A successful selection requires a holistic assessment of chemical, thermal, and mechanical stresses in addition to the immediate physical environment.

A Framework for Selecting the Right PTFE Packing

Choosing the correct packing is an engineering decision that balances multiple interacting variables. Viewing the selection process through a multi-faceted framework ensures reliability and optimal performance.

Operational Environment: Moisture, UV, and Abrasives

This is the most direct interpretation of "environmental factors." It refers to the immediate physical conditions surrounding the packing.

Constant or intermittent exposure to moisture can affect certain filler materials or lubricants within the packing, while prolonged UV radiation can degrade some polymers over time.

The presence of abrasive media, such as crystals, sand, or other particulates in a fluid, is a primary cause of mechanical failure. PTFE fiber packing is specifically engineered for these demanding applications.

Chemical Compatibility: The Core Strength of PTFE

For most applications, chemical exposure is the single most important factor, and it is where PTFE excels.

PTFE is renowned for its exceptional chemical resistance, being nearly inert to a vast range of acids, solvents, and bases. This makes it a default choice for systems handling aggressive media like concentrated sulfuric or nitric acid.

However, for certain extreme oxidizers or molten alkali metals, specialized PTFE packing, such as PTFE graphite packing, may be required to ensure complete compatibility.

Thermal Stability: From Cryogenics to High Heat

The operational temperature range has a profound effect on the packing's sealing capability and material integrity.

PTFE packing performs reliably across an exceptionally wide temperature spectrum, from cryogenic temperatures up to 250°C (482°F). This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures.

Pressure and Mechanical Stress

The system's pressure and the mechanical stress on the packing are critical operational demands that cannot be overlooked.

High-pressure applications require packing that can resist extrusion and maintain a consistent seal. The braiding and density of the PTFE packing play a significant role here.

Furthermore, PTFE's inherently low coefficient of friction is a major advantage. It minimizes wear on shafts and stems, reducing maintenance needs and lowering the energy consumption of rotating equipment.

Understanding the Trade-offs and Broader Context

A truly informed decision acknowledges the nuances and potential limitations of any material choice.

Not All PTFE is Created Equal

Standard PTFE is a versatile workhorse, but its properties can be enhanced by combining it with other materials.

Blends with graphite improve thermal conductivity and self-lubrication, while other fillers can increase rigidity or meet specific regulatory standards, such as FDA requirements for food and pharmaceutical use.

The Environmental Impact of Manufacturing

While PTFE is stable and inert during its service life, its production carries environmental considerations that may be relevant to corporate sustainability goals.

The manufacturing process can involve perfluorinated compounds like PFOA, which have been linked to environmental contamination. This factor does not affect the packing's performance but is part of a complete lifecycle assessment.

Installation and Maintenance Considerations

The practical aspects of using the packing are also a valid part of the selection process.

Some packing types, such as certain PTFE gland packings, are designed for easier cutting and installation. This can significantly reduce downtime during routine maintenance or emergency repairs.

Making the Right Choice for Your Application

To make a definitive selection, align the properties of the packing with the primary demand of your specific application.

- If your primary focus is handling abrasive media: Select a specialized PTFE fiber packing designed for high wear resistance.

- If your primary focus is resisting aggressive chemicals: Standard, high-quality PTFE packing is an excellent choice for its near-universal chemical inertness.

- If your primary focus is operating in extreme temperatures: Confirm the packing’s specified range, as PTFE’s stability from cryogenic lows to over 250°C covers most industrial needs.

- If your primary focus is minimizing equipment wear and energy use: Leverage PTFE's inherently low-friction properties to protect shafts and reduce operational costs.

Ultimately, a systematic evaluation of the complete operational environment is the key to selecting a packing that delivers safety, reliability, and long-term performance.

Summary Table:

| Environmental Factor | Key Consideration for PTFE Packing |

|---|---|

| Moisture & UV Light | Can degrade some fillers/lubricants; check compatibility. |

| Abrasive Media | Requires specialized PTFE fiber packing for high wear resistance. |

| Chemical Exposure | PTFE offers near-universal chemical inertness. |

| Temperature Range | Stable from cryogenic temperatures up to 250°C (482°F). |

| Pressure & Friction | Braiding density affects pressure handling; low friction reduces wear. |

Select the optimal PTFE packing with confidence.

At KINTEK, we manufacture high-performance PTFE components, including seals and custom packing solutions, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a packing material perfectly tailored to withstand your specific environmental challenges, from abrasive slurries to aggressive chemicals.

Contact our experts today for a consultation and let us help you enhance the safety, reliability, and longevity of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What should be considered when selecting a CNC machining service for PTFE? Key Factors for Precision Parts

- What is PTFE commonly known as and why is it used for gaskets? | Superior Sealing Solutions

- What makes PTFE O-Rings superior to those made of other materials? Unmatched Performance in Extreme Conditions

- What are the operational limit values for PTFE piston rings? Optimize Speed, Pressure & Temperature

- How do PTFE expansion bellows contribute to pollution control systems? Enhance System Integrity & Safety

- How should one select the right PTFE Teflon gasket? A Guide to Matching Material to Your Application

- How does carbon filler cause corrosion when combined with aluminum? Understanding Galvanic Corrosion Risks

- What industrial applications commonly use PTFE gaskets? Solve Your Toughest Sealing Challenges