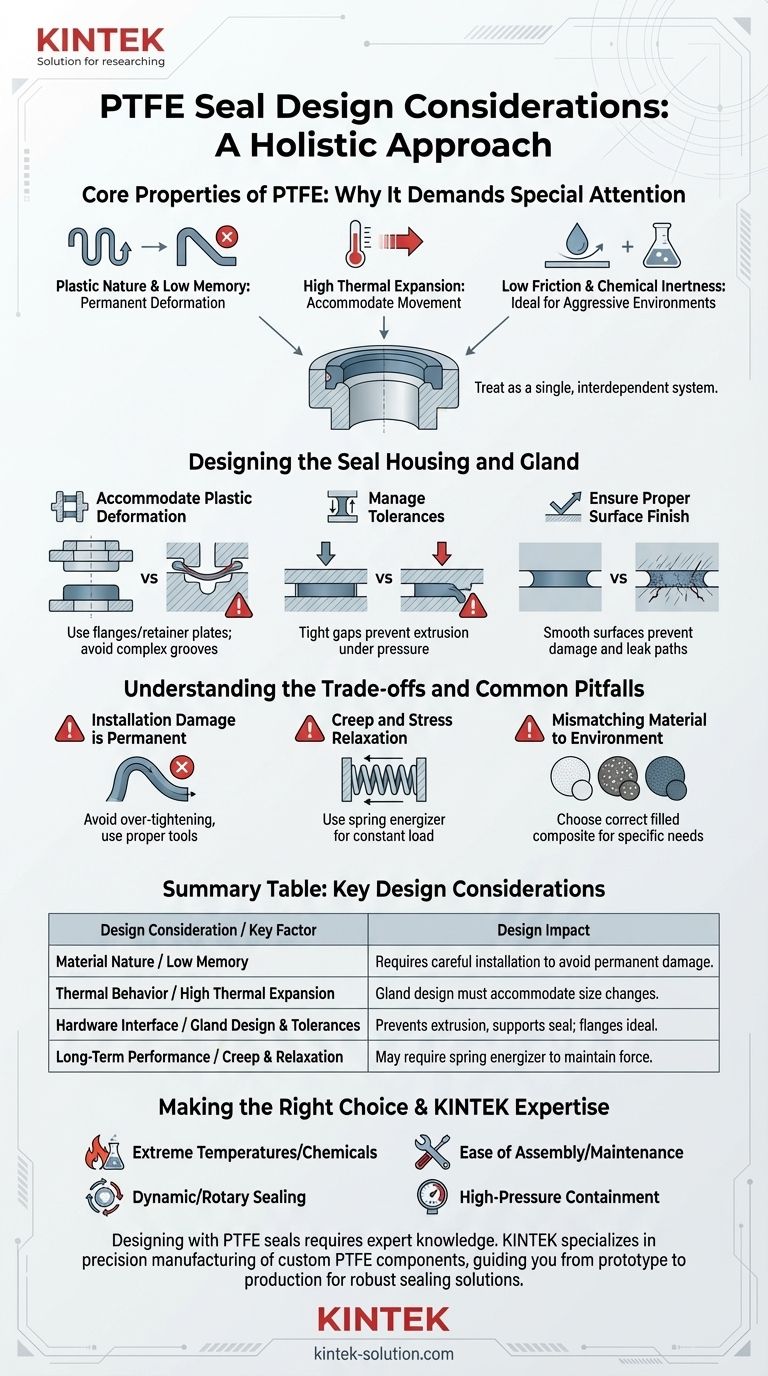

When designing with PTFE seals, you must focus on the interaction between the seal's material properties, its geometric shape, and the design of the housing or gland it fits into. Key considerations include accounting for PTFE's plastic nature, its high rate of thermal expansion, and ensuring the surrounding hardware is designed for easy, damage-free installation.

The central challenge with PTFE seals is that they are not simple drop-in replacements for elastomeric O-rings. Their unique "plastic" memory and sensitivity to installation require a holistic design approach where the seal, its housing, and the assembly process are treated as a single, interdependent system.

The Core Properties of PTFE: Why It Demands Special Attention

To design effectively with PTFE, you must first understand the material's fundamental characteristics, which differ significantly from common elastomers like rubber.

Its "Plastic" Nature and Low Memory

Unlike rubber, which springs back to its original shape, PTFE is a plastic material. When deformed, it does not fully return to its initial form.

This property, known as low memory or stress relaxation, is the single most important factor driving design. Bending or twisting a PTFE seal during installation can cause permanent damage and compromise its ability to seal effectively.

High Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than most metals.

Your design must accommodate this movement to maintain a consistent sealing force across the entire operating temperature range. Failure to do so can lead to leaks at low temperatures or excessive stress at high temperatures.

Low Friction and Chemical Inertness

PTFE's extremely low coefficient of friction and near-universal chemical resistance are its primary advantages.

These properties reduce wear in dynamic applications, prevent contamination build-up, and allow the seal to function in aggressive chemical and high-temperature environments where other materials would fail.

Designing the Seal Housing and Gland

The hardware surrounding the seal is as critical as the seal itself. A poorly designed gland will cause even the best seal to fail.

Accommodate Plastic Deformation

The sealing pocket or "gland" must be designed to support the PTFE material. Complex machined grooves that require the seal to be stretched or twisted into place are a primary source of failure.

Designs that can be assembled over the seal, such as using flanges or retainer plates, are far superior as they prevent installation damage.

Manage Tolerances

Because PTFE can creep or flow under pressure, the clearance gaps in the hardware must be tightly controlled.

Proper tolerances prevent the seal material from extruding into the gap under high pressure, which would lead to rapid seal failure.

Ensure Proper Surface Finish

The surfaces that contact the seal must be smooth and free of defects. Scratches or burrs on the hardware can create leak paths and damage the soft PTFE material during installation or operation.

Understanding the Trade-offs and Common Pitfalls

While powerful, PTFE seals are not without challenges. Acknowledging these limitations is key to a successful design.

Installation Damage is Permanent

This is the most common failure mode. Over-tightening a bolted flange can deform the seal, while forcing a seal into a difficult groove can create permanent flat spots or creases.

Always use proper tools, follow torque specifications, and ensure components are correctly aligned. The design should, wherever possible, make correct installation the easiest path.

Creep and Stress Relaxation

Under a constant load (compression), PTFE will slowly deform over time. This "creep" can reduce the sealing force, potentially leading to leaks.

For critical applications, this is often counteracted by incorporating a spring energizer (a metal spring inside the PTFE jacket) to provide a constant, live load that compensates for material relaxation.

Mismatching Material to Environment

"PTFE" is a family of materials. While virgin PTFE is highly capable, filled PTFE composites (mixed with materials like carbon, glass, or bronze) are used to enhance properties like wear resistance, thermal conductivity, and creep resistance.

Using the wrong grade—for example, virgin PTFE in a high-wear dynamic application—can lead to premature failure.

Making the Right Choice for Your Application

Your specific goal will determine which design considerations to prioritize.

- If your primary focus is extreme temperatures or chemicals: Prioritize selecting the correct filled PTFE composite and ensure the gland design accommodates for high thermal expansion and contraction.

- If your primary focus is dynamic or rotary sealing: The seal's lip geometry, low-friction properties, and the inclusion of a spring energizer are the most critical factors for long service life.

- If your primary focus is ease of assembly and maintenance: Emphasize a simple housing design with features like split glands, retainer plates, or flanges that prevent seal damage during installation.

- If your primary focus is high-pressure containment: Pay closest attention to tight hardware tolerances and designs that provide anti-extrusion support for the seal.

By treating the seal and its surrounding hardware as a unified system, you can reliably harness the unique advantages of PTFE for your most demanding applications.

Summary Table:

| Design Consideration | Key Factor | Design Impact |

|---|---|---|

| Material Nature | Low Memory / Plastic | Requires careful installation to avoid permanent damage. |

| Thermal Behavior | High Thermal Expansion | Gland design must accommodate size changes with temperature. |

| Hardware Interface | Gland Design & Tolerances | Prevents extrusion and supports the seal; flanges/retainer plates are ideal. |

| Long-Term Performance | Creep & Stress Relaxation | May require a spring energizer to maintain sealing force over time. |

Designing with PTFE seals requires expert knowledge to avoid common pitfalls and ensure long-term reliability. KINTEK specializes in the precision manufacturing of PTFE components, including custom seals, for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical interplay between material properties, seal geometry, and gland design. Let our expertise guide you from prototype to high-volume production to create a robust, high-performance sealing solution for your specific application.

Contact KINTEK today to discuss your project requirements and leverage our precision manufacturing capabilities.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the limitations of PTFE coated fasteners regarding abrasion resistance? The Trade-Off for Superior Chemical Protection

- How does a Stretched PTFE Lip Rotary Shaft Seal work? A Low-Friction, Springless Sealing Solution

- What customization options are available for PTFE sheets? Engineer the Perfect Material for Your Application

- What are the differences between Teflon and rubber sealed bearings? Choose the Right Seal for Speed or Protection

- Why is PTFE preferred for applications involving friction? Achieve Unmatched Efficiency and Reliability

- What are the key features and benefits of PTFE bushings? Achieve Maintenance-Free Operation in Demanding Environments

- What are the common applications of PTFE beyond non-stick cookware? Unlock High-Performance Solutions

- How are PTFE gaskets used in the petrochemical industry? Ensure Leak-Proof Seals for Aggressive Chemicals