In short, a technical plastic is a polymer engineered for specific, demanding applications where common, everyday plastics would fail. These materials are chemically designed to provide a superior balance of properties, such as high mechanical strength and thermal resistance, while remaining relatively easy to process.

The core distinction is one of purpose. While commodity plastics are made for mass-market, low-stress uses like packaging, technical plastics are precision-engineered to function as reliable components in machines, electronics, and vehicles.

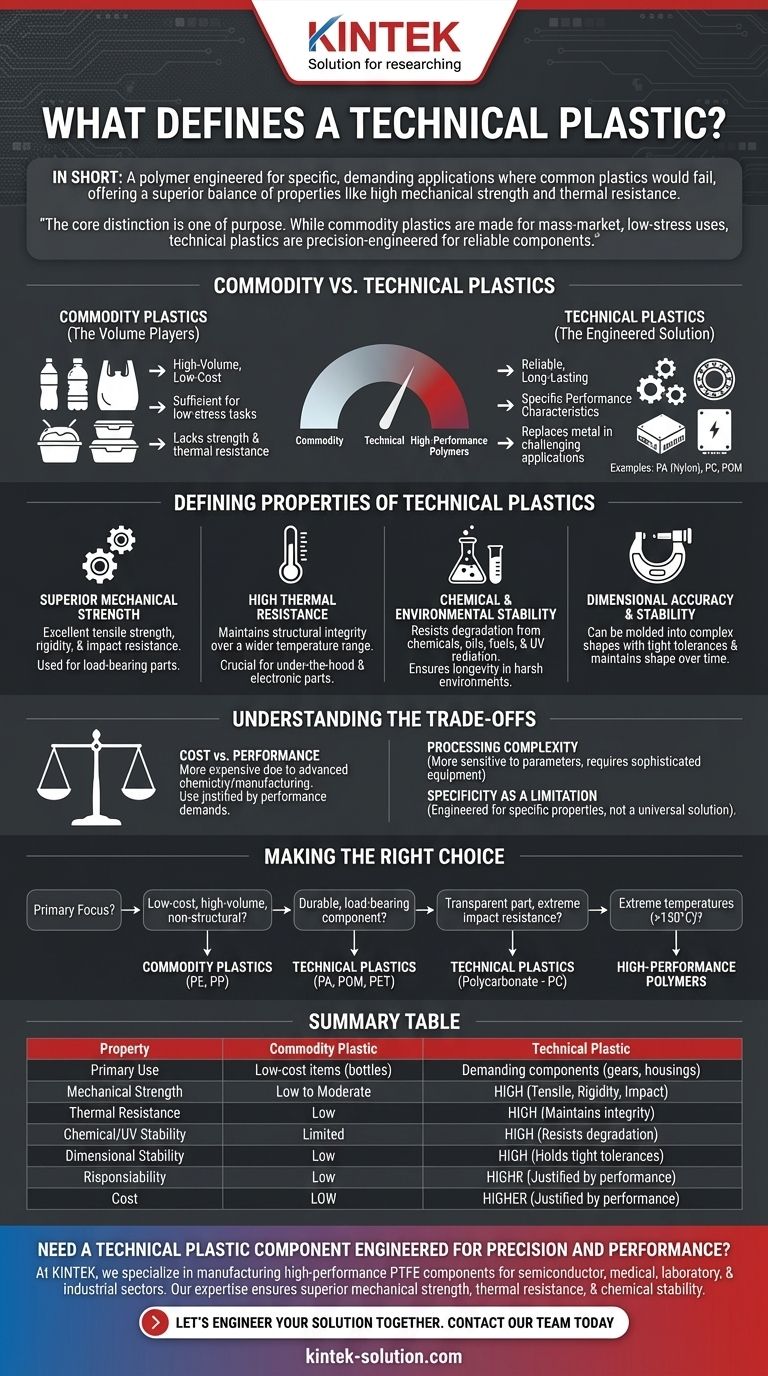

What Separates Technical from Commodity Plastics?

To understand technical plastics, it's best to contrast them with the materials you encounter most often. The world of polymers is a spectrum, and these two categories occupy very different positions.

Commodity Plastics: The Volume Players

Commodity plastics, like Polyethylene (PE) and Polypropylene (PP), are defined by their high-volume production and low cost. They are the workhorses for disposable and everyday items such as bottles, bags, and food containers.

Their properties are sufficient for these tasks, but they lack the strength, temperature resistance, or dimensional stability required for more demanding engineering roles.

Technical Plastics: The Engineered Solution

Technical plastics are developed to fill the gap between commodity plastics and more exotic, high-performance polymers. They are designed to be reliable, long-lasting components.

These materials, such as Polyamide (PA, or Nylon), Polycarbonate (PC), and Acetal (POM), are selected for their specific performance characteristics, enabling them to replace metal or other materials in challenging applications. They are often modified with additives like glass fibers or stabilizers to further enhance their properties for a given task.

The Defining Properties of Technical Plastics

A plastic is designated as "technical" when it reliably delivers on a combination of key performance metrics that commodity plastics cannot match.

Superior Mechanical Strength

Technical plastics offer excellent tensile strength, rigidity, and impact resistance. This allows them to be used for load-bearing parts like gears, bearings, and structural housings that must endure physical stress without failing.

High Thermal Resistance

Unlike commodity plastics that may soften or warp at moderately high temperatures, technical plastics maintain their structural integrity and strength over a wider temperature range. This is critical for automotive under-the-hood components or electronic enclosures.

Chemical and Environmental Stability

These polymers are formulated to resist degradation from exposure to chemicals, oils, fuels, and UV radiation. This stability ensures longevity and reliability in harsh operating environments.

Dimensional Accuracy and Stability

Technical plastics can be molded into complex shapes with very tight tolerances and will maintain that shape over time and across temperature changes. This property, known as dimensional stability, is essential for creating precise, interlocking parts.

Understanding the Trade-offs

While technical plastics offer significant advantages, they are not a universal solution. Acknowledging their limitations is key to using them effectively.

Cost vs. Performance

The most significant trade-off is cost. The advanced chemistry and manufacturing processes make technical plastics considerably more expensive than commodity plastics. Their use is only justified when the application's performance demands it.

Processing Complexity

While generally designed for processability, technical plastics can be more sensitive to manufacturing parameters like temperature and moisture compared to simpler polymers. Achieving optimal properties often requires more sophisticated equipment and process control.

Specificity Can Be a Limitation

A plastic engineered for high rigidity might be brittle, while one designed for high-impact strength may have lower thermal resistance. The specialization that makes them effective for one application can make them unsuitable for another.

Making the Right Choice for Your Goal

Selecting the correct class of plastic is fundamental to a successful project. Your primary goal will dictate the best path forward.

- If your primary focus is low-cost, high-volume production for non-structural items: Commodity plastics like PE or PP are the clear and correct choice.

- If your primary focus is creating a durable, load-bearing component for a machine or vehicle: Technical plastics like PA, POM, or PET are engineered for this purpose.

- If your primary focus is a transparent part that requires extreme impact resistance: Technical plastics, specifically Polycarbonate (PC), are the industry standard.

- If your primary focus is an application requiring performance at extreme temperatures above 150°C: You may need to look beyond technical plastics to the next tier of high-performance polymers.

Ultimately, choosing a technical plastic is a deliberate decision to invest in performance where it matters most.

Summary Table:

| Property | Commodity Plastic | Technical Plastic |

|---|---|---|

| Primary Use | Low-cost, high-volume items (bottles, bags) | Demanding components (gears, bearings, housings) |

| Mechanical Strength | Low to Moderate | High (Tensile Strength, Rigidity, Impact) |

| Thermal Resistance | Low | High (Maintains integrity at elevated temps) |

| Chemical/UV Stability | Limited | High (Resists degradation) |

| Dimensional Stability | Low | High (Holds tight tolerances) |

| Cost | Low | Higher (Justified by performance) |

Need a technical plastic component engineered for precision and performance?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication ensures your technical plastic parts deliver the superior mechanical strength, thermal resistance, and chemical stability your project requires.

Let's engineer your solution together. Contact our team today to discuss your project needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What is the dissipation factor of PTFE? A Guide to Virgin vs. Filled Grades

- What are the durability characteristics of PTFE? Superior Chemical & Thermal Resistance for Demanding Applications

- How is PTFE used in lubrication applications? Achieve Superior Friction Reduction

- How is PTFE used in pharmaceutical and medical applications? Essential for Safety & Efficiency

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- How do fillers enhance the properties of PTFE? Improve Wear, Strength, and Thermal Performance

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application