The primary challenge in constructing long PTFE umbilical cords is achieving a continuous, seamless tube over extensive lengths—often 250 meters or more—without using traditional joints. Standard joining methods like bonding introduce foreign chemicals, which can leach into the high-purity gases the umbilical is designed to carry and compromise the entire system.

The core engineering conflict is balancing the need for extreme length with the non-negotiable requirement for absolute chemical purity. This makes specialized, contaminant-free joining techniques like PTFE welding the only viable, albeit complex, solution.

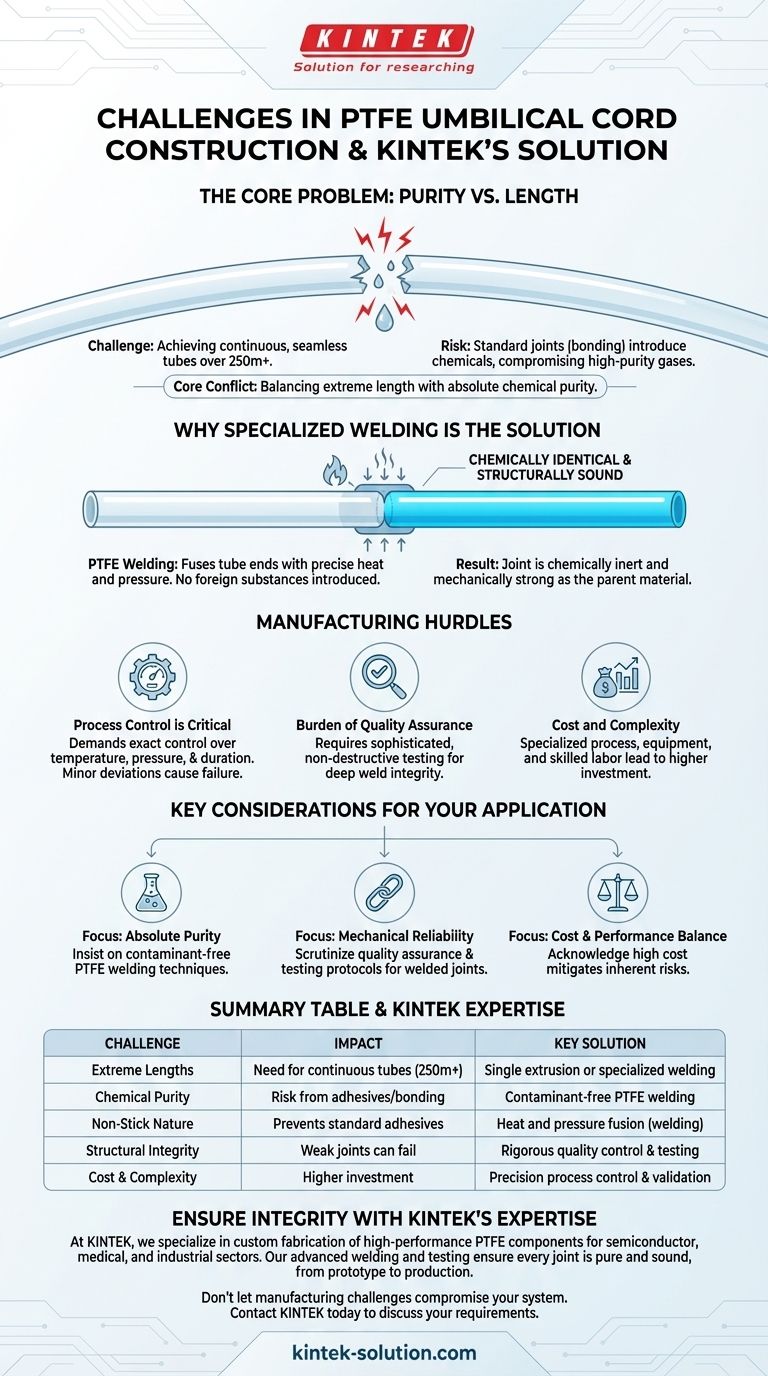

The Core Problem: Purity vs. Length

The construction of PTFE umbilicals presents a unique set of material science and manufacturing challenges. The properties that make PTFE desirable are the same ones that make it difficult to work with over long, continuous spans.

The Need for Extreme Length

Umbilical cords, by their nature, must connect distant points without interruption. Lengths of 250 meters are common in applications like aerospace or industrial gas transfer, where a continuous line is necessary for operational integrity and safety.

The Contamination Risk of Standard Joints

The central issue is purity. PTFE is chosen for its extreme chemical inertness. Using adhesives, bonding agents, or mechanical fittings would introduce foreign materials that could degrade, outgas, or leach contaminants into the sensitive fluids or gases being transported.

The Non-Stick Nature of PTFE

PTFE is famously non-stick, a property that makes it nearly impossible to join with conventional adhesives. This inherent material characteristic forces manufacturers to seek alternative methods for creating long, continuous lengths from shorter, more manageable sections.

Why Specialized Welding is the Solution

To overcome the limitations of bonding and mechanical fittings, the industry relies on a highly controlled process of welding PTFE to itself. This creates a seamless, monolithic tube.

How PTFE Welding Works

Specialized PTFE welding uses a combination of precise heat and pressure to fuse two ends of a PTFE tube together. The material melts and re-forms as a single, continuous piece without the introduction of any foreign substance.

Preserving Chemical Integrity

A successful weld is chemically identical to the parent PTFE material. This means the joint is just as inert and non-reactive as the rest of the tube, ensuring that no impurities are introduced at the seam.

Ensuring Structural Reliability

The goal of the weld is not just chemical purity but also mechanical strength. A properly executed weld must be as strong as the original tube, capable of withstanding the same pressure, temperature, and physical stresses as a seamless extrusion.

Understanding the Manufacturing Hurdles

While PTFE welding provides an effective solution, the process itself is a significant challenge requiring immense precision and rigorous quality control.

Process Control is Critical

Welding PTFE is unforgiving. It demands exact control over temperature, pressure, and duration. Any minor deviation can result in a weak, brittle, or incomplete bond that could fail under operational stress.

The Burden of Quality Assurance

Verifying the integrity of a weld deep inside a 250-meter umbilical is a major hurdle. It requires sophisticated, non-destructive testing methods to ensure every welded joint is free from microscopic flaws or imperfections.

Cost and Complexity

This specialized manufacturing process is significantly more complex and expensive than using standard off-the-shelf components. The investment in equipment and skilled labor is substantial, reflecting the critical nature of the final product.

Key Considerations for Your Application

Choosing the right approach depends entirely on the requirements of your system. Understanding these challenges allows for better procurement and design decisions.

- If your primary focus is absolute chemical purity: You must insist on either a single, joint-free extrusion or a cord constructed with fully validated, contaminant-free PTFE welding techniques.

- If your primary focus is mechanical reliability over long distances: The quality assurance and testing protocol for any welded joints is the most critical factor to scrutinize in a supplier's process.

- If your primary focus is balancing cost and performance: Acknowledge that the high cost of this specialized manufacturing is a direct result of mitigating the inherent risks of contamination and failure.

Ultimately, recognizing the intricate challenges of PTFE umbilical construction is the first step toward ensuring the integrity and safety of your critical systems.

Summary Table:

| Challenge | Impact | Key Solution |

|---|---|---|

| Achieving Extreme Lengths | Need for continuous tubes over 250m | Single extrusion or specialized welding |

| Chemical Purity & Contamination | Risk from adhesives/bonding agents | Contaminant-free PTFE welding |

| PTFE's Non-Stick Nature | Prevents use of standard adhesives | Heat and pressure fusion (welding) |

| Structural Integrity of Joints | Weak joints can fail under stress | Rigorous quality control and testing |

| Cost & Manufacturing Complexity | Higher investment in equipment and expertise | Precision process control and validation |

Ensure the Integrity of Your Critical Systems with KINTEK's Expertise

Constructing reliable, high-purity PTFE umbilical cords is a complex challenge that demands precision manufacturing and rigorous quality control. At KINTEK, we specialize in the custom fabrication of high-performance PTFE components, including complex umbilical systems for the semiconductor, medical, laboratory, and industrial sectors.

Our advanced PTFE welding techniques and non-destructive testing protocols ensure that every joint is chemically pure and structurally sound, even in extreme-length applications. We work with you from prototype to high-volume production, delivering solutions that meet your exact specifications for purity, reliability, and performance.

Don't let manufacturing challenges compromise your system's integrity. Contact KINTEK today to discuss your PTFE umbilical cord requirements and learn how our expertise can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the different forms of PTFE sheet gasket materials? Select the Right PTFE for Your Sealing Needs

- What are the three types of PTFE materials used for gaskets? Select the Right Seal for Your Application

- In which industries are PTFE diaphragms commonly used? For Superior Chemical Resistance and Purity

- What are the limitations of POM as a ball valve seat material? Key Risks & Safer Alternatives

- What factors should be considered when choosing a PTFE gasket? Ensure a Reliable, Leak-Free Seal

- What are PTFE slide plates and how are they used? Achieve Controlled Movement in Critical Infrastructure

- What are the main benefits of using a Teflon sheet for heat press? Achieve Flawless, Professional Transfers

- What are the key properties of PTFE gaskets that make them effective sealing solutions? Unmatched Chemical & Temperature Resistance