In chemical manufacturing, Teflon coating delivers a powerful combination of benefits, primarily centered on its extreme chemical inertness and low-friction surface. This dual capability protects process equipment like pipelines, containers, and machinery from corrosion by aggressive chemicals, while also ensuring smooth operation and preventing product contamination. The result is a significant boost in equipment lifespan, operational efficiency, and process reliability.

The core value of Teflon coating in the chemical industry is not a single feature, but its unique ability to create a chemically inert, non-stick, and thermally stable barrier. This transforms vulnerable equipment into highly resilient assets, directly reducing maintenance costs and protecting product purity.

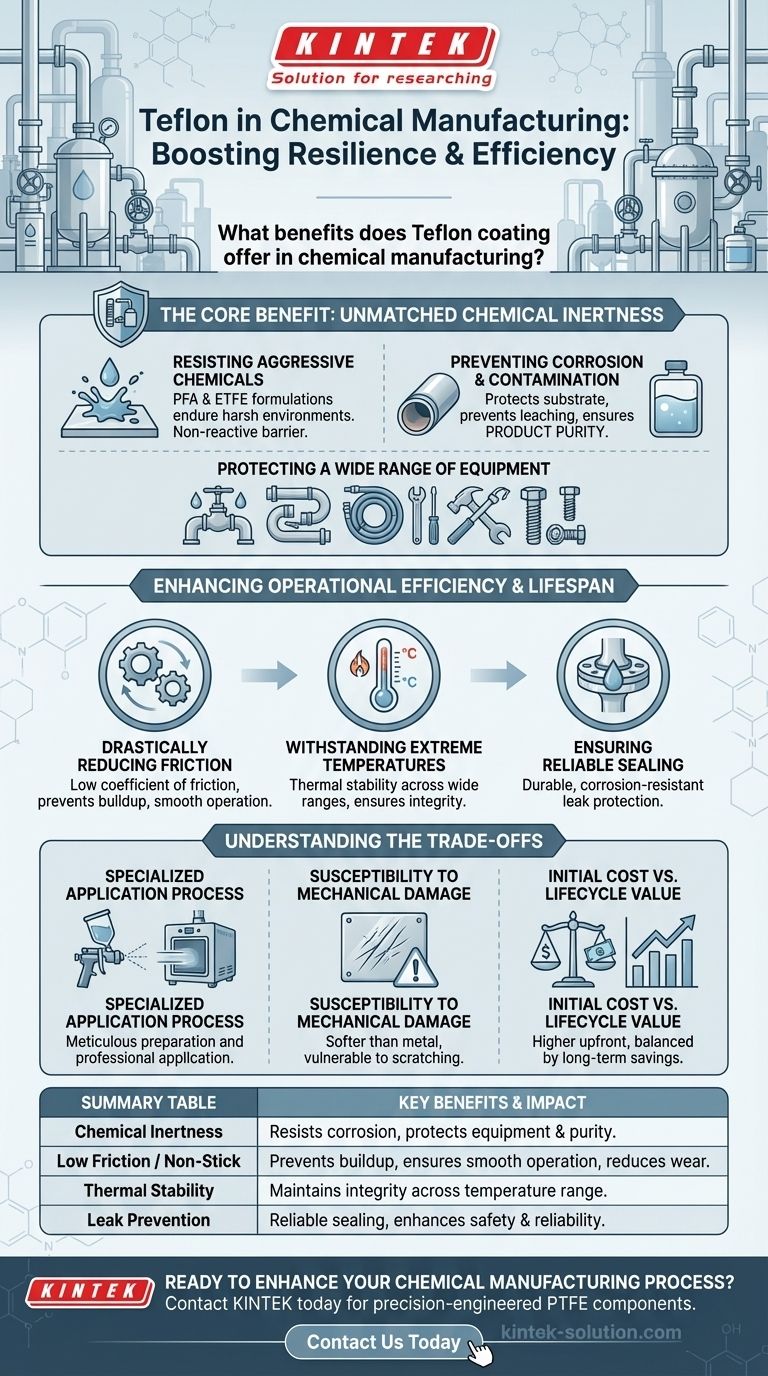

The Core Benefit: Unmatched Chemical Inertness

The primary reason Teflon coatings are indispensable in chemical manufacturing is their ability to resist attack from nearly all industrial chemicals and solvents. This creates a robust, protective shield for critical equipment.

Resisting Aggressive Chemicals

Teflon, particularly formulations like PFA (perfluoroalkoxy alkane) and ETFE (ethylene tetrafluoroethylene), is engineered to endure harsh chemical environments. It creates a non-reactive barrier that does not crack, melt, or erode, even when in contact with highly corrosive substances.

Preventing Corrosion and Contamination

This inert barrier serves two critical functions. First, it protects the underlying substrate—whether metal or glass—from being corroded by the process chemicals. Second, it prevents the substrate material from leaching into the product, which is essential for maintaining product purity.

Protecting a Wide Range of Equipment

The application of Teflon is not limited to large vessels. It provides a vital protective layer for pipelines, hoses, tools, bolts, and other fasteners, adding durability and preventing seizure in environments where corrosion would otherwise be rampant.

Enhancing Operational Efficiency and Lifespan

Beyond simple chemical resistance, Teflon's physical properties directly contribute to smoother, more cost-effective operations by protecting the mechanical integrity of equipment.

Drastically Reducing Friction

Teflon possesses an extremely low coefficient of friction. This "non-stick" quality is crucial for moving parts, preventing buildup of process materials, and ensuring that valves and machinery operate smoothly with less wear and tear.

Withstanding Extreme Temperatures

Teflon coatings maintain their integrity across a wide range of temperatures. This thermal stability is essential for chemical processes that involve heating or cooling cycles, ensuring the protective layer remains intact and functional.

Ensuring Reliable Sealing

In chemical processing, preventing leaks is a matter of safety and efficiency. Teflon seals are ideal for these harsh environments, providing durable and reliable leak protection due to their corrosion resistance and ability to perform under extreme conditions.

Understanding the Trade-offs

While the benefits are significant, a balanced perspective requires acknowledging the practical considerations of using high-performance coatings.

Specialized Application Process

Applying a Teflon coating is not a simple painting process. It requires meticulous surface preparation, professional application, and specific curing protocols to ensure proper adhesion and achieve the desired performance characteristics.

Susceptibility to Mechanical Damage

While chemically robust, Teflon coatings can be softer than metal substrates. They can be susceptible to scratching or abrasive wear, which could compromise the protective barrier if not handled appropriately.

Initial Cost vs. Lifecycle Value

The upfront investment for Teflon coating is typically higher than for other coatings. However, this cost must be weighed against the long-term savings from reduced maintenance, significantly longer equipment life, and minimized production downtime.

Making the Right Choice for Your Process

Ultimately, leveraging Teflon coating is a strategic decision to enhance the resilience and efficiency of your operation.

- If your primary focus is product purity and preventing contamination: Teflon's chemical inertness provides an unparalleled non-reactive surface for vessels, pipes, and containers.

- If your primary focus is extending equipment life and reducing maintenance: Its combined resistance to corrosion, friction, and high temperatures protects everything from large tanks to small fasteners, minimizing downtime.

- If your primary focus is operational safety and reliability: Teflon-lined hoses and seals provide durable, leak-proof performance in the most aggressive chemical environments.

By integrating Teflon coatings, you are investing in the long-term stability and profitability of your chemical manufacturing process.

Summary Table:

| Key Benefit | Impact on Chemical Manufacturing |

|---|---|

| Chemical Inertness | Resists corrosion from aggressive chemicals, protecting equipment and product purity. |

| Low Friction / Non-Stick | Prevents material buildup, ensures smooth operation, and reduces wear on moving parts. |

| Thermal Stability | Maintains integrity across a wide temperature range, ideal for heating/cooling processes. |

| Leak Prevention | Provides reliable sealing in harsh environments, enhancing safety and operational reliability. |

Ready to enhance your chemical manufacturing process with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment gains unmatched chemical resistance, extended lifespan, and superior product purity.

Whether you need prototypes or high-volume orders, we deliver solutions tailored to your specific requirements.

Contact us today to discuss how our PTFE components can protect your assets and optimize your operations!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the advantages of using filled PTFE materials? Enhance Strength, Wear, and Stability

- Are there any chemicals that PTFE is not compatible with? Key Exceptions for Safe Use

- How does Teflon demonstrate superior chemical resistance? Unlocking Its Molecular Fortress

- What is the dispersion method of producing PTFE and what are its products? Ideal for Thin Coatings and Films

- What are the key advantages of PTFE as a solid lubricant? Clean, Stable Lubrication for Extreme Conditions

- Why is PTFE highly resistant to chemicals? Unmatched Inertness for Demanding Applications

- What modifications can be made to PTFE for enhanced performance? Boost Wear Resistance & Strength with Fillers

- What are the four types of Teflon resins and their key properties? Choose the Right Fluoropolymer for Your Application