In short, spring energized Teflon seals provide reliable, long-term sealing in extreme operating conditions where standard elastomeric seals fail. They are specifically engineered to handle aggressive chemicals, cryogenic or high temperatures, high pressures, and high speeds. This is achieved by combining the superior material properties of a PTFE (Teflon) jacket with the constant mechanical force of a metal spring energizer.

The core benefit is not just a single feature, but a powerful synergy. The seal's PTFE jacket provides resistance to temperature and chemicals, while the internal spring ensures a constant, adaptive sealing force that compensates for wear, misalignment, and the hardening or compression set issues that plague traditional seals.

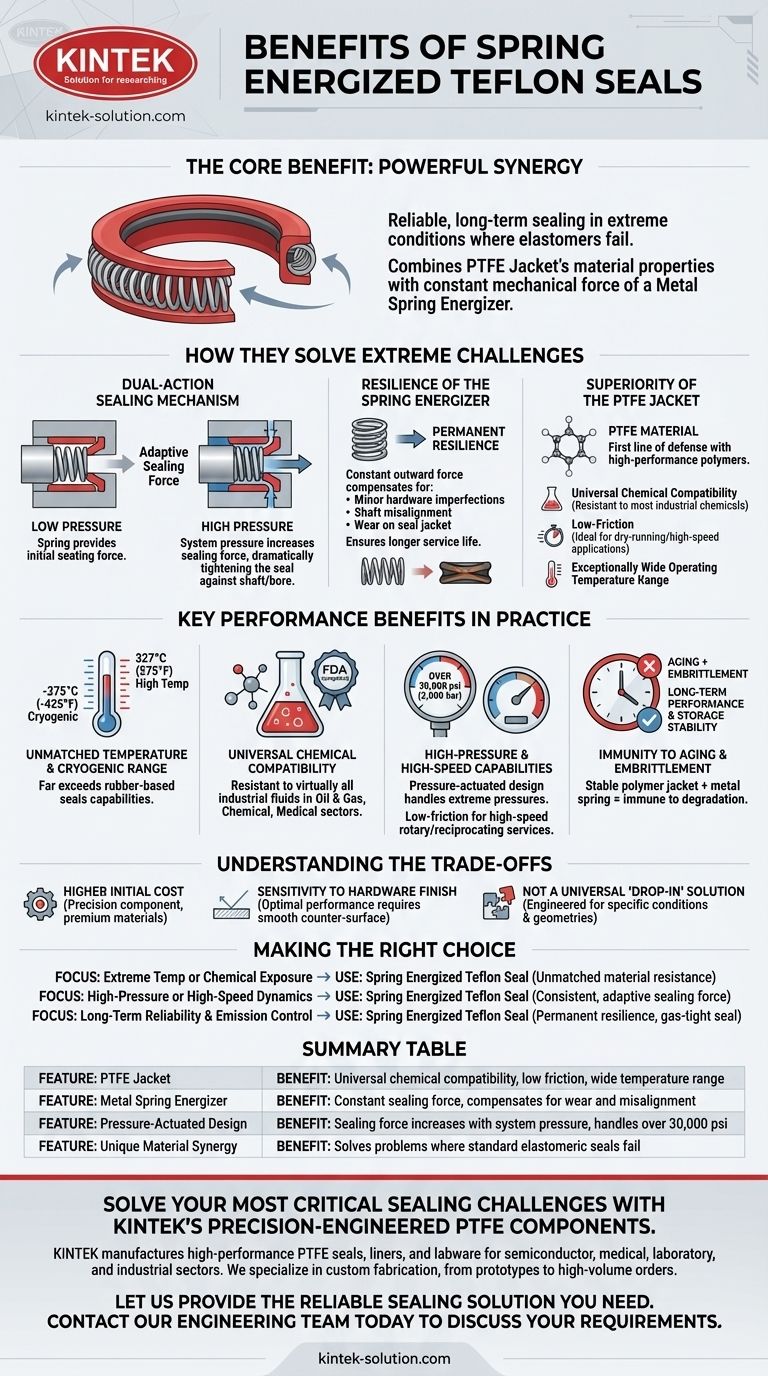

How They Solve Extreme Sealing Challenges

Spring energized seals are not a simple replacement for an O-ring; they are a purpose-built solution for applications that push beyond the limits of conventional materials. Their effectiveness comes from a unique three-part design.

The Dual-Action Sealing Mechanism

A spring energized seal consists of a precision-machined polymeric jacket, typically made of PTFE, and a corrosion-resistant metal spring energizer.

At low pressure, the spring provides the initial seating force, pushing the lips of the jacket outward to create a tight seal. As system pressure increases, that pressure enters the U-shaped cavity of the jacket, dramatically increasing the sealing force against the shaft or bore.

The Resilience of the Spring Energizer

Unlike elastomeric seals which can harden, lose their shape (compression set), or "take a set" over time, the metal spring provides permanent resilience.

This constant outward force allows the seal to compensate for minor hardware imperfections, shaft misalignment, and most importantly, wear on the seal jacket itself, ensuring a reliable seal over a much longer service life.

The Superiority of the PTFE Jacket

The jacket material is the seal's first line of defense. Using PTFE and other high-performance polymers provides benefits that elastomers cannot match.

Key material advantages include universal chemical compatibility, low-friction for dry-running or high-speed applications, and an exceptionally wide operating temperature range.

Key Performance Benefits in Practice

The design of a spring energized Teflon seal translates directly into measurable performance advantages in critical applications.

Unmatched Temperature and Cryogenic Range

These seals maintain their integrity and sealing ability in conditions from cryogenic lows of -275°C (-425°F) up to high temperatures of 327°C (575°F), far exceeding the capabilities of rubber-based seals.

Universal Chemical Compatibility

Due to the chemical inertness of PTFE, these seals are resistant to virtually all industrial chemicals and fluids. This makes them ideal for aggressive media in oil & gas, chemical processing, and medical applications, with many grades also being FDA-compliant.

High-Pressure and High-Speed Capabilities

The pressure-actuated design allows these seals to handle extreme pressures, often exceeding 30,000 psi (2,000 bar). Their low-friction properties also make them suitable for high-speed rotary and reciprocating services where traditional seals would quickly overheat and fail.

Immunity to Aging and Embrittlement

The combination of a stable polymer jacket and a metal spring means the seal is immune to aging, embrittlement, and compression set. This ensures long-term performance and storage stability, a critical factor for spare parts and mission-critical equipment.

Understanding the Trade-offs

While highly effective, spring energized seals are a specialized component, and their use involves important considerations.

Higher Initial Cost

As a precision-engineered component made from premium materials, a spring energized seal has a significantly higher unit cost than a standard O-ring or lip seal. This cost is justified by its performance and extended service life in applications where failure is not an option.

Sensitivity to Hardware Finish

To achieve optimal performance and seal life, the hardware's surface finish is critical. The low-friction PTFE jacket performs best against a smooth, non-abrasive counter-surface. Ignoring recommended hardware finishing can lead to premature wear.

Not a Universal "Drop-In" Solution

These seals are not a one-size-fits-all replacement. They are engineered for specific operating conditions and gland geometries. Effective implementation requires careful consideration of the application's pressure, temperature, media, and hardware dynamics.

Making the Right Choice for Your Application

Selecting the right seal requires matching its capabilities to your primary engineering challenge.

- If your primary focus is extreme temperature or chemical exposure: A spring energized Teflon seal offers unmatched material resistance where elastomers would rapidly degrade and fail.

- If your primary focus is high-pressure or high-speed dynamics: The design ensures a consistent sealing force that adapts to system pressure and maintains integrity during rapid motion.

- If your primary focus is long-term reliability and fugitive emission control: The spring's permanent resilience compensates for wear and prevents compression set, ensuring a gas-tight seal that extends service life and meets environmental regulations.

By understanding their unique design principles, you can confidently specify spring energized Teflon seals to solve your most critical engineering challenges.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Jacket | Universal chemical compatibility, low friction, wide temperature range |

| Metal Spring Energizer | Constant sealing force, compensates for wear and misalignment |

| Pressure-Actuated Design | Sealing force increases with system pressure, handles over 30,000 psi |

| Unique Material Synergy | Solves problems where standard elastomeric seals fail |

Solve your most critical sealing challenges with KINTEK's precision-engineered PTFE components.

Spring energized seals are a specialty application requiring exacting manufacturing standards. KINTEK manufactures high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring your components meet the precise demands of your application.

Let us provide the reliable sealing solution you need. Contact our engineering team today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary advantages of expanded PTFE? Achieve Superior Sealing and Performance

- What is the significance of the creep relaxation rate in PTFE gaskets? Ensure Long-Term Sealing Reliability

- What precautions should be taken when handling PTFE gaskets? Ensure Longevity & Performance

- What are the advantages of mechanical seals with PTFE rings? Superior Chemical & Thermal Resistance

- What are the key advantages of PTFE in rotary shaft seals? Superior Performance in Extreme Conditions

- What are the key technical features of Teflon backup rings? Essential Support for High-Pressure Seals

- How does PTFE's friction coefficient compare to other materials? The Benchmark for Low-Friction Performance

- In which industries is RPTFE particularly suitable for throttle valves? Ensure Purity and Durability