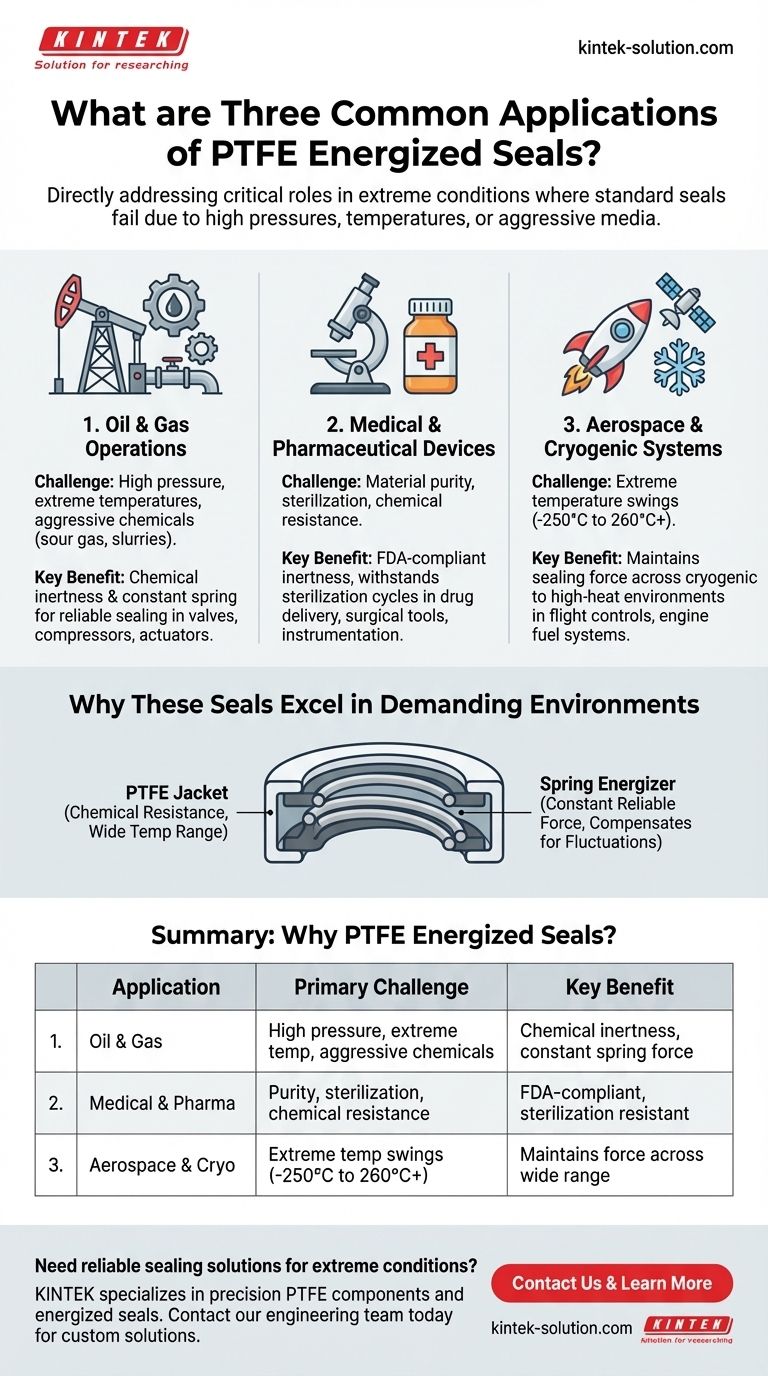

To be direct, three of the most common and demanding applications for PTFE energized seals are in Oil & Gas Operations, Medical & Pharmaceutical Devices, and Aerospace & Cryogenic Systems. These high-performance seals are specified for critical roles where standard elastomeric seals would quickly fail due to extreme temperatures, high pressures, or aggressive chemical media.

The core reason PTFE energized seals are chosen for these industries is their unique combination of material properties. The PTFE jacket offers exceptional chemical inertness and a wide temperature tolerance, while the internal spring energizer provides a constant, reliable sealing force that elastomeric seals cannot maintain in harsh conditions.

Why These Seals Excel in Demanding Environments

A PTFE energized seal consists of two primary components: a precision-machined polymer jacket (typically PTFE) and a metallic spring energizer. This design provides a unique set of advantages.

The Role of the PTFE Jacket

The PTFE jacket is the component in contact with the media. Its key benefit is its extreme resistance to virtually all industrial chemicals, solvents, and corrosive fluids. It also has a very low coefficient of friction and can operate across an enormous temperature range.

The Function of the Spring Energizer

Unlike a traditional O-ring that relies on its own material elasticity, the energized seal uses a metal spring. This spring applies a constant, concentrated force to the sealing lips, ensuring a tight seal even at very low pressures, during temperature fluctuations, or when the PTFE material naturally tries to creep over time.

Application Deep Dive: Oil & Gas Operations

The oil and gas industry presents some of the most challenging sealing environments, characterized by high pressures, extreme temperatures, and aggressive chemicals.

The Challenge of Downhole Conditions

Equipment operating thousands of feet underground must withstand sour gas, abrasive slurries, and immense pressures. Standard seals would quickly degrade and fail, leading to catastrophic equipment failure.

Where They Are Used

PTFE energized seals are critical in valves, compressors, hydraulic actuators, and other oilfield equipment. Their chemical resistance prevents degradation, and the spring energizer ensures a reliable seal against high-pressure gas and fluids.

Application Deep Dive: Medical & Pharmaceutical

In medical and pharmaceutical applications, the primary concerns are material purity, chemical inertness, and the ability to withstand sterilization processes.

The Need for Sterility and Purity

Materials used in this field cannot leach contaminants into the process media or react with sensitive drugs. PTFE is an ideal material as it is inherently pure and can be manufactured to meet stringent FDA requirements.

Critical Sealing in Devices and Manufacturing

You will find these seals in drug delivery systems, surgical tools, instrumentation, and pharmaceutical manufacturing equipment. Their ability to handle aggressive cleaning agents and sterilization cycles makes them suitable for both reusable and disposable applications.

Application Deep Dive: Aerospace & Cryogenics

The aerospace sector demands absolute reliability across an incredible range of temperatures, from the intense heat of a jet engine to the cryogenic cold of liquid fuel.

Surviving Extreme Temperature Swings

PTFE energized seals are one of the few sealing solutions that remain functional and reliable from cryogenic temperatures (around -250°C) up to very high heat (over 260°C). The metal spring compensates for the thermal contraction and expansion of the seal jacket.

Key Aerospace Applications

These seals are indispensable in flight controls, jet engine fuel systems, air management systems, and hydraulic controls. Specific uses include engine cooling lines, turbine seals, fuel injectors, and cabin pressure systems where sealing failure is not an option.

Understanding the Trade-offs

While highly effective, PTFE energized seals are not a universal solution. Their specialized nature comes with specific considerations.

Higher Initial Cost

These are engineered components designed for high performance. Their cost is significantly higher than that of a standard elastomeric O-ring or lip seal.

Installation Sensitivity

The rigid nature of the PTFE jacket can make installation more challenging than with a flexible rubber seal. Proper tooling and procedure are often required to prevent damage to the sealing lips during assembly.

Performance Over-Specification

For simple, static applications with benign media and ambient temperatures, a PTFE energized seal is often unnecessary. A standard, more cost-effective seal will typically suffice in these less demanding conditions.

Making the Right Choice for Your Goal

Selecting the correct seal requires a clear understanding of your application's primary challenges.

- If your primary focus is reliability in extreme environments: The chemical resistance and wide temperature range of a PTFE energized seal make it the definitive choice.

- If your primary focus is hygiene and material purity: The inherent inertness of PTFE is critical for medical, food processing, and pharmaceutical applications.

- If your primary focus is a low-cost solution for a standard application: A traditional elastomeric O-ring or lip seal is likely the more practical and cost-effective option.

Ultimately, choosing an energized seal is an investment in reliability where performance is the most critical factor.

Summary Table:

| Application | Primary Challenge | Key Benefit of PTFE Energized Seal |

|---|---|---|

| Oil & Gas Operations | High pressure, extreme temperatures, aggressive chemicals | Chemical inertness and constant spring force for reliable sealing |

| Medical & Pharmaceutical | Material purity, sterilization, chemical resistance | FDA-compliant inertness and ability to withstand sterilization cycles |

| Aerospace & Cryogenics | Extreme temperature swings (-250°C to 260°C+) | Maintains sealing force across cryogenic to high-heat environments |

Need reliable sealing solutions for extreme conditions?

At KINTEK, we specialize in manufacturing precision PTFE components, including energized seals, for the most demanding applications in semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get the exact sealing solution your operation requires.

Contact our engineering team today to discuss how our PTFE seals can enhance the reliability and performance of your critical equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does Teflon contribute to contamination control in sensitive environments? A Guide to Purity & Performance

- What role do fillers play in structured PTFE? Enhancing Strength, Wear, and Thermal Performance

- What are the key dielectric properties of PTFE that make it suitable for wires and cables? Ensuring Signal Integrity in Extreme Conditions

- What industries use custom PTFE parts and for what purposes? Solve Critical Challenges with High-Performance Materials

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- How does the mechanical strength of PTFE Teflon washers benefit their use? Achieve Reliable Sealing in High-Pressure Systems

- How does the sealing performance of PTFE gaskets benefit industrial applications? Ensure Leak-Free Reliability in Harsh Environments

- What advantages do PTFE gaskets offer in terms of friction and wear? Achieve Low-Friction, Long-Lasting Seals