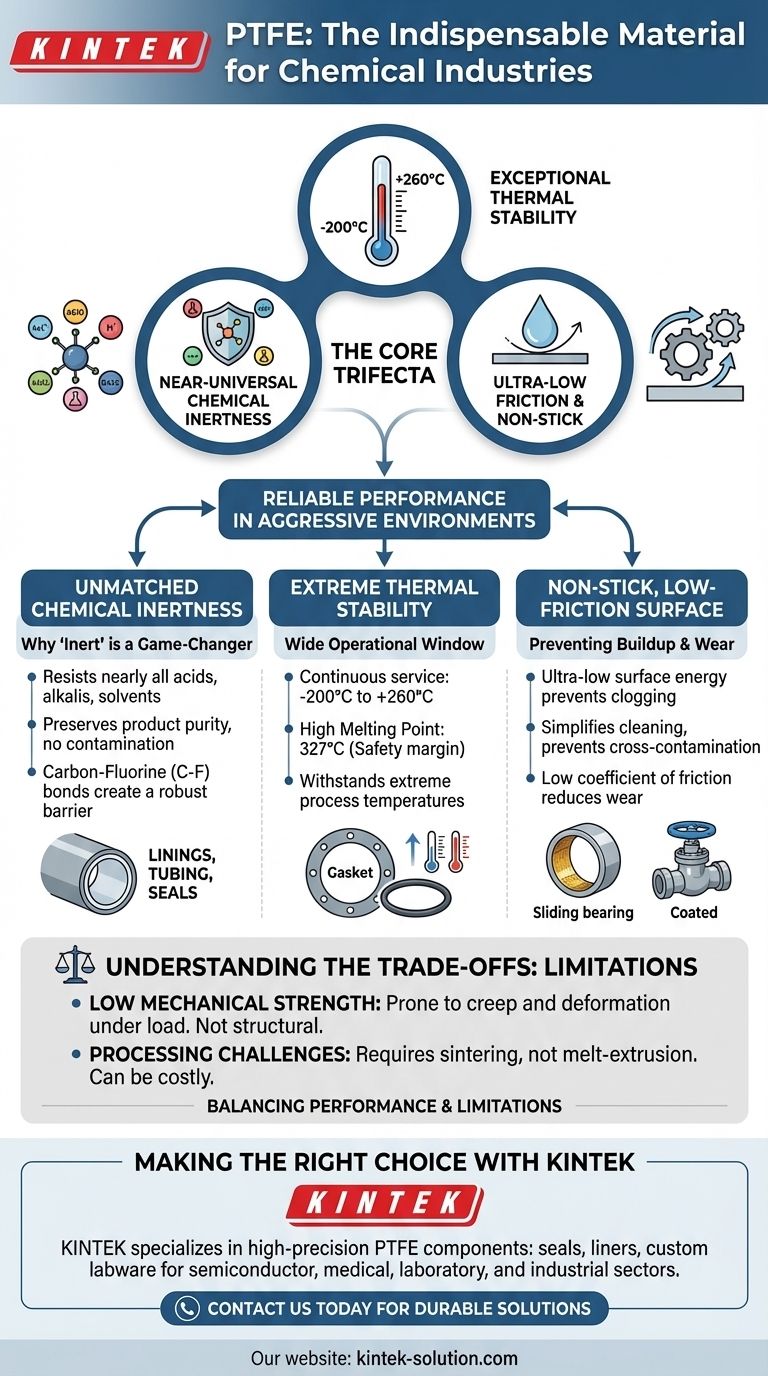

At its core, the value of Polytetrafluoroethylene (PTFE) in chemical industries stems from a unique combination of three properties: near-universal chemical inertness, exceptional thermal stability, and an extremely low-friction, non-stick surface. This trifecta makes it one of the most reliable and versatile materials for handling aggressive substances and extreme temperatures where other polymers would quickly fail.

The central challenge in chemical processing is material integrity—finding something that won't corrode, contaminate the product, or fail under heat. PTFE is the definitive solution for lining vessels, pipes, and creating seals in these environments, but its utility is defined by a critical trade-off: its unmatched chemical performance comes at the cost of low mechanical strength.

The Core Pillar: Unmatched Chemical Inertness

Why "Inert" is a Game-Changer

In the chemical industry, reactivity is the enemy of purity and safety. PTFE is famously chemically inert, meaning it does not react with nearly all known acids, alkalis, solvents, and other aggressive chemicals.

This property is paramount for applications like vessel linings, tubing, and seals. Using PTFE ensures that the material itself neither corrodes nor leaches contaminants into the chemical process, preserving product purity and extending equipment lifespan.

The Strength of Fluorine Bonds

PTFE's inertness is a direct result of its molecular structure. It consists of a carbon chain completely shielded by a sheath of tightly bonded fluorine atoms.

The Carbon-Fluorine (C-F) bond is one of the strongest single bonds in organic chemistry. This molecular stability makes it incredibly difficult for other chemicals to break the bonds and react with the polymer chain.

Performance Under Pressure: Extreme Thermal Stability

A Wide Operational Window

Chemical processes often involve extreme temperatures, from cryogenic applications to high-heat reactions. PTFE maintains its integrity across an exceptionally broad temperature range.

It has a continuous service temperature from approximately -200°C (-328°F) up to +260°C (+500°F). This allows it to be used reliably in processes that other plastics and elastomers cannot withstand.

High Melting Point for Safety

Beyond its operational range, PTFE features a very high melting point of 327°C (621°F). This provides a significant safety margin against temperature spikes in industrial processes, preventing catastrophic failure of components like gaskets or seals.

Efficiency and Purity: The Non-Stick, Low-Friction Surface

Preventing Contamination and Buildup

PTFE has an ultra-low surface energy, which gives it its famous non-stick quality. In chemical plants, this prevents viscous materials from building up on the internal surfaces of pipes, valves, and reactors.

This property not only improves flow efficiency but also simplifies cleaning and reduces the risk of cross-contamination between batches.

Implications for Sealing and Movement

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This makes it an ideal material for seals, gaskets, and bearings that operate in corrosive environments.

The low-friction surface reduces wear and tear on moving parts and minimizes the energy required to operate them, enhancing both reliability and efficiency.

Understanding the Trade-offs: The Limitations of PTFE

Low Mechanical Strength and Rigidity

This is the most critical limitation of PTFE. While chemically robust, it has low mechanical strength and is prone to "creep"—deformation under sustained load.

It is not a structural material. It cannot be used for high-load-bearing applications unless it is reinforced with fillers like glass, carbon, or bronze.

Processing Challenges

PTFE's high melting point and melt viscosity mean it cannot be processed using conventional melt-extrusion or injection molding techniques common to other thermoplastics.

Instead, it is typically processed through compression and sintering, a method more akin to powder metallurgy. This can make manufacturing complex shapes more difficult and costly.

Relative Cost

While PTFE offers the best price-to-performance ratio among advanced fluoropolymers, it is significantly more expensive than commodity plastics. Its use is therefore justified only when its unique properties are a critical requirement for safety and performance.

Making the Right Choice for Your Application

Choosing the right material requires balancing performance needs against physical limitations and cost. PTFE is an exceptional problem-solver, but only for the right problems.

- If your primary focus is product purity and corrosion resistance: Use PTFE for linings in vessels, pipes, and tubing where it will contact highly reactive chemicals.

- If your primary focus is reliable sealing in extreme environments: PTFE gaskets, O-rings, and valve seats provide an unmatched seal against aggressive media across a wide temperature range.

- If your primary focus is reducing friction in moving parts: Specify PTFE for bearings, slide plates, or coatings where chemical exposure prevents the use of traditional lubricants.

- If your primary focus is a structural, load-bearing component: Avoid using pure PTFE and instead consider mechanically stronger materials or filled grades of PTFE designed for improved rigidity.

Ultimately, understanding both the immense strengths and the clear limitations of PTFE is the key to leveraging it successfully in demanding chemical applications.

Summary Table:

| Key Property | Why It Matters in Chemical Industries |

|---|---|

| Chemical Inertness | Resists virtually all acids, alkalis, and solvents, ensuring product purity and preventing corrosion. |

| Thermal Stability | Performs reliably from -200°C to +260°C, withstanding extreme process temperatures. |

| Non-Stick, Low Friction | Prevents material buildup, simplifies cleaning, and reduces wear on seals and moving parts. |

| Key Limitation | Low mechanical strength and prone to creep; not suitable for high structural loads. |

Need reliable PTFE components for your demanding chemical applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from PTFE's superior chemical resistance and thermal stability, enhancing safety, purity, and operational longevity.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let us provide the durable, chemically inert solution your process needs.

Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the key chemical resistance properties of PTFE? Discover Its Near-Universal Inertness

- Why is virgin PTFE preferred for certain applications? Ensuring Absolute Purity for Sensitive Industries

- What are the key properties of Teflon (PTFE) that make it suitable for industrial applications?

- What are the main advantages of PTFE materials? Unlock Extreme Performance and Reliability

- What is PTFE's resistance to chemicals? Discover the Ultimate Chemical-Resistant Polymer

- What are the key qualities of PTFE material? Unlock Extreme Chemical, Thermal & Electrical Resistance

- Why is PTFE highly regarded in the industry? Unmatched Chemical & Thermal Resistance

- What unique characteristic of PTFE prevents geckos from sticking to it? Its Extremely Low Surface Energy