In short, Polytetrafluoroethylene (PTFE) is a polymer defined by extremes. Its mechanical properties are characterized by an exceptionally low coefficient of friction and high flexibility, but this is paired with low tensile strength and stiffness. Thermally, it is one of the most stable plastics available, maintaining its properties over an incredibly wide temperature range from -200°C to +260°C.

PTFE is not a material you choose for strength; you choose it for its unrivaled slipperiness, chemical inertness, and ability to perform in extreme temperatures where most other materials fail. Understanding this core trade-off is the key to using it effectively.

A Deep Dive into PTFE's Mechanical Profile

PTFE’s mechanical behavior is unlike that of typical rigid plastics. It is soft, flexible, and uniquely slippery, which dictates its primary uses.

The Defining Trait: Exceptionally Low Friction

The most famous property of PTFE is its extremely low dynamic coefficient of friction, which typically ranges from 0.05 to 0.10.

This is one of the lowest friction coefficients of any known solid material. This quality is responsible for its use in non-stick coatings and low-wear, self-lubricating bearings.

Flexibility and Toughness

PTFE is not a brittle material. It exhibits a very high elongation at break, often between 200% and 400%, meaning it can stretch significantly before failing.

It also has good toughness, with an Izod impact strength of around 3.5 ft-lbs/in (160 J/m). This combination means it can absorb impact without fracturing and is easily bent or conformed into shapes.

Strength and Stiffness (or Lack Thereof)

Compared to engineering plastics, PTFE has low mechanical strength. Its tensile strength is moderate, typically in the range of 1,500 to 5,000 psi (10-35 MPa).

Furthermore, it is a very flexible material with a low flexural modulus of around 72,000 psi (0.5 GPa). This means it is not suitable for structural applications where rigidity and load-bearing capacity are required.

Understanding the Unmatched Thermal Stability

PTFE’s performance in extreme temperatures is a primary reason for its selection in demanding aerospace, industrial, and electrical applications.

Extreme Operating Temperature Range

PTFE’s key thermal advantage is its massive service temperature window. It remains functional and stable from cryogenic temperatures of -200°C (-328°F) up to a continuous service temperature of 260°C (500°F).

This allows it to be used in environments that would cause most other polymers to become brittle or melt.

High Melting Point

The material has a very high melting point for a polymer, centered around 327°C (620°F).

It is important to note, however, that it can begin to degrade and release fumes if heated above its service temperature, a phenomenon known as polymer fume fever.

Crucial Trade-offs and Limitations

To use PTFE correctly, you must be aware of its significant limitations. Its unique strengths are accompanied by equally important weaknesses.

The Challenge of Creep (Cold Flow)

The most critical mechanical limitation of PTFE is its susceptibility to creep, also known as cold flow.

Because it is a soft material, it will slowly and permanently deform when subjected to a constant compressive load, even at room temperature. This must be accounted for in seal and gasket design, often by using fillers or bonded cores.

Low Hardness

PTFE is a soft material, with a Shore D hardness of around 50-55. This makes it prone to scratching and abrasion and reinforces its unsuitability for high-contact, high-load mechanical parts without reinforcement.

High Thermal Expansion

While thermally stable, PTFE has a high coefficient of linear thermal expansion. This means it expands and contracts significantly more than metals with changes in temperature.

This mismatch must be managed in designs where PTFE is fastened to or enclosed by metal components to avoid high stress or component failure.

Heat Deflection Under Load

The heat deflection temperature of PTFE at 66 psi is only around 121°C (250°F).

This is much lower than its maximum service temperature. It reveals a critical trade-off: while PTFE can survive high temperatures, its ability to resist deformation under load is significantly reduced as temperature increases.

Making the Right Choice for Your Application

Selecting PTFE is about matching its extreme properties to a specific problem.

- If your primary focus is low friction or chemical inertness: PTFE is an ideal choice for seals, gaskets, non-stick coatings, bushings, and high-purity fluid handling components.

- If your primary focus is performance across a wide temperature range: It is an excellent material for electrical wire insulation, aerospace components, and industrial parts exposed to both cryogenic and high-heat conditions.

- If your primary focus is structural strength or load-bearing capacity: You should avoid using pure PTFE and consider a different engineering plastic or a filled/reinforced grade of PTFE.

Ultimately, PTFE is a specialized problem-solver, not a general-purpose material.

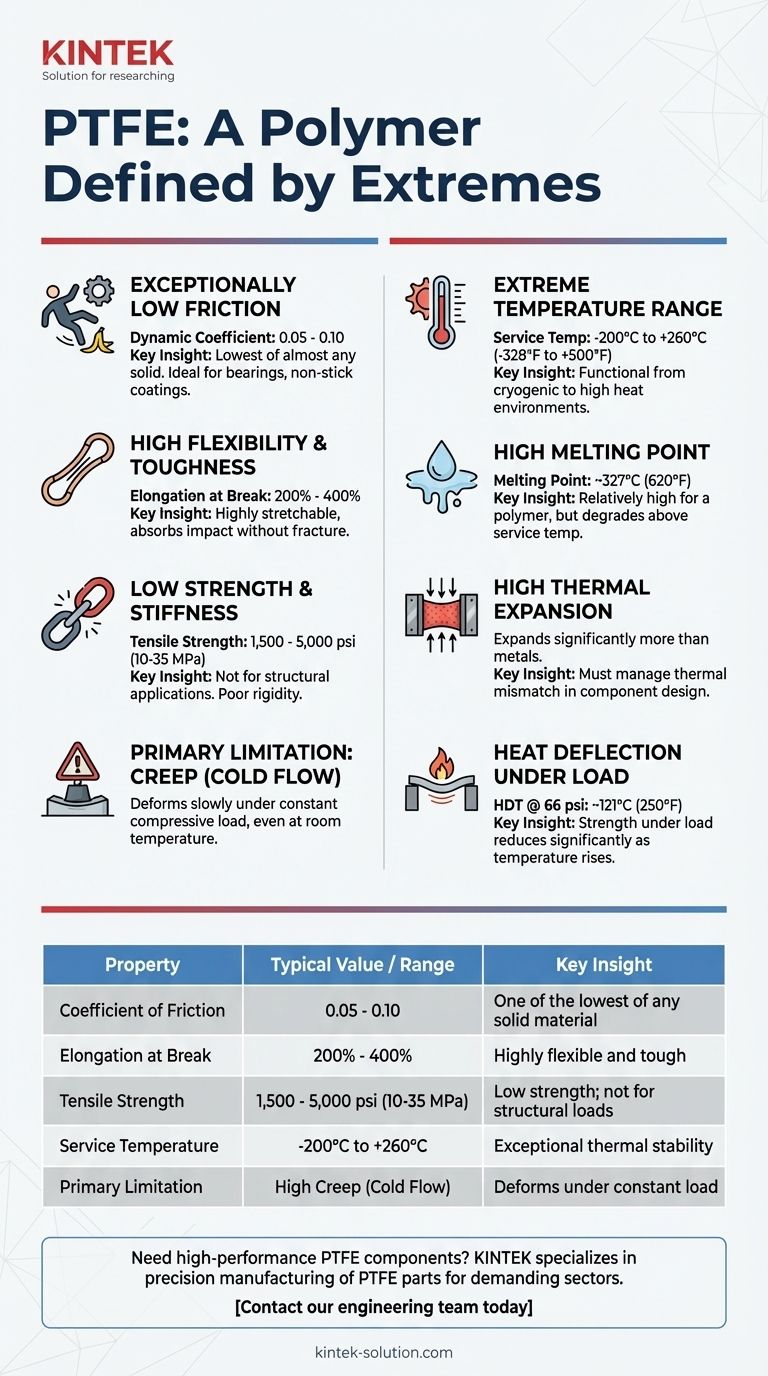

Summary Table:

| Property | Typical Value / Range | Key Insight |

|---|---|---|

| Coefficient of Friction | 0.05 - 0.10 | One of the lowest of any solid material |

| Elongation at Break | 200% - 400% | Highly flexible and tough |

| Tensile Strength | 1,500 - 5,000 psi (10-35 MPa) | Low strength; not for structural loads |

| Service Temperature | -200°C to +260°C | Exceptional thermal stability |

| Primary Limitation | High Creep (Cold Flow) | Deforms under constant load |

Need high-performance PTFE components that leverage these unique properties?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and specialized industrial sectors. We understand the critical trade-offs of PTFE and can help you design parts that maximize its low friction, chemical inertness, and thermal stability while mitigating limitations like creep.

Whether you require prototypes or high-volume production, our expertise ensures your components perform reliably in the most demanding environments.

Contact our engineering team today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- When did the industrial production of PTFE begin? From Military Secret to Industrial Revolution

- What aerospace applications use Teflon? Unlock Reliability in Extreme Environments

- How can PTFE adhere to another surface? Unlock Permanent Bonding with Chemical Etching

- Why is understanding Teflon's friction mechanism important? Master Its Self-Lubricating Wear for Better Applications

- Why is PTFE chemically resistant and what applications benefit from this? Discover the Ultimate Material for Harsh Environments

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What are the benefits of glass-filled PTFE? Achieve Superior Strength & Wear Resistance

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance