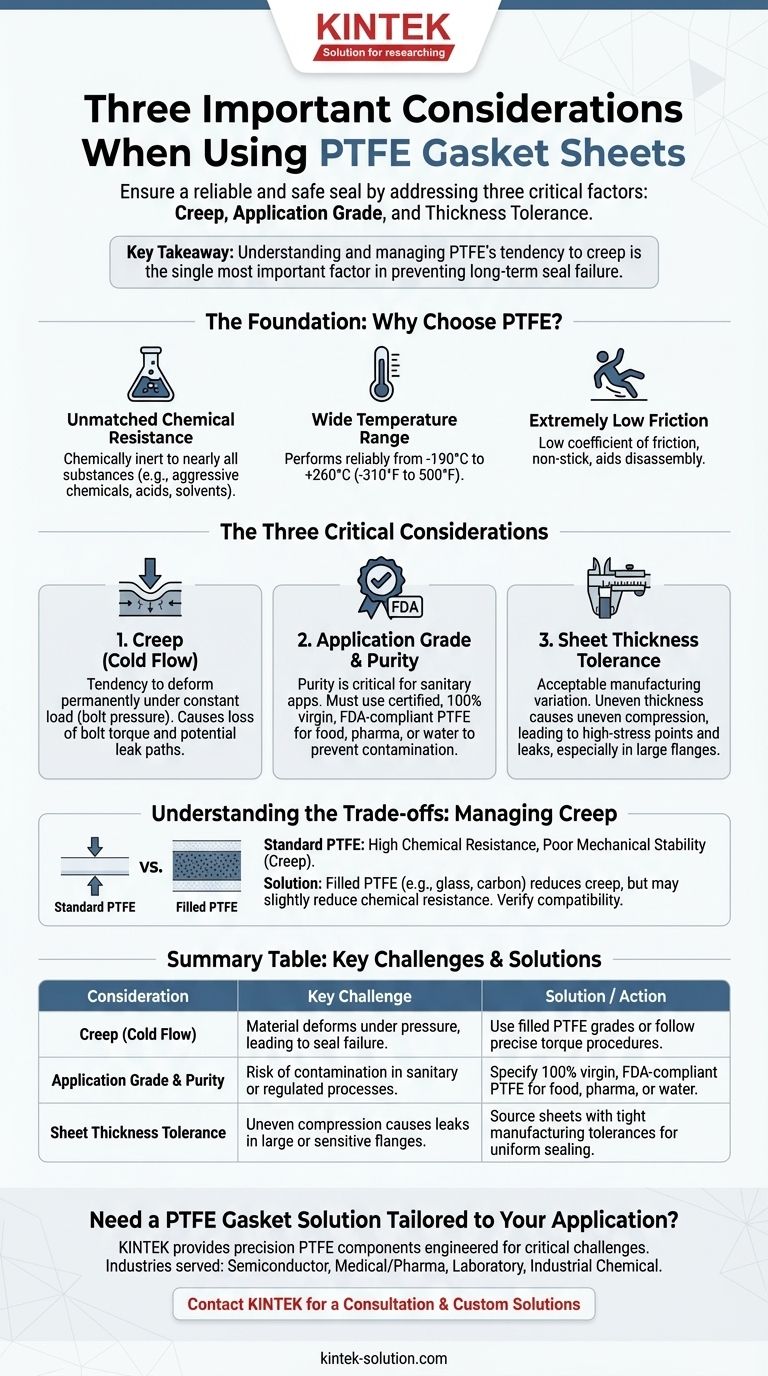

When using PTFE gasket sheets, there are three critical considerations you must address to ensure a reliable and safe seal. These are the material's natural tendency to creep or "flow" under pressure, the strict requirement for application-specific grades (especially in sanitary contexts), and the impact of manufacturing tolerances on sheet thickness.

While PTFE offers unparalleled chemical and temperature resistance, its unique physical properties mean you cannot treat it like a conventional rubber or fiber gasket. Understanding and managing its tendency to creep is the single most important factor in preventing long-term seal failure.

The Foundation: Why Choose PTFE?

Before examining its limitations, it's important to understand why PTFE (polytetrafluoroethylene) is a premier choice for gasketing in demanding environments. Its properties make it a problem-solver for applications where other materials would quickly degrade.

Unmatched Chemical Resistance

PTFE is chemically inert to nearly all substances. This makes it the default choice for sealing aggressive chemicals, acids, and solvents that would destroy other gasket materials. The main exceptions are elemental fluorine and hot nitric acid.

Wide Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum, typically from -190°C up to +260°C (-310°F to 500°F). This allows it to be used in everything from cryogenic services to high-temperature processing.

Extremely Low Friction

The material has a very low coefficient of friction and non-stick properties. This can be advantageous in certain dynamic applications and helps with easy disassembly of flanged joints without gasket residue.

The Three Critical Considerations Explained

While its strengths are significant, overlooking PTFE's unique weaknesses is a common cause of failure. You must account for the following three factors.

1. Creep (Cold Flow)

Creep is the tendency of a solid material to deform permanently over time when subjected to a constant load, such as the pressure from tightened bolts on a flange.

Standard PTFE is a relatively soft material that is highly susceptible to creep. This means that after the initial bolt-up, the gasket material can slowly "flow" or squeeze out from between the flanges. This process results in a loss of bolt torque, reducing the compressive force on the gasket and creating a potential leak path.

2. Application Grade and Purity

Not all PTFE is created equal. The purity and grade of the material are critical, especially for regulated industries.

For any application involving food, pharmaceuticals, or drinking water, you must use virgin PTFE that is specifically certified as FDA-compliant. Using a non-compliant or recycled grade can introduce contaminants, leading to product spoilage and severe regulatory issues.

3. Sheet Thickness Tolerance

Thickness tolerance refers to the acceptable manufacturing variation in the thickness of the gasket sheet. A sheet with poor tolerance may be thicker in some areas and thinner in others.

When a gasket is cut from such a sheet, the uneven thickness will result in uneven compression across the flange face. This creates high-stress points and low-pressure areas, which are prime locations for leaks to develop, particularly in large-diameter or sensitive flange connections.

Understanding the Trade-offs

The core trade-off with standard PTFE is its incredible chemical resistance versus its poor mechanical stability (creep).

Managing Creep

To combat creep, manufacturers often add filler materials like glass, carbon, or silica to the PTFE. This creates a "filled PTFE" gasket sheet that is much more resistant to cold flow. However, these fillers can sometimes slightly reduce the gasket's chemical resistance, so you must verify compatibility with your specific process media.

The Low-Friction Downside

While low friction is often a benefit, it can exacerbate the effects of creep. Because the material is so slippery, it can be squeezed out of a flange more easily if over-torqued or if the flange surfaces are too smooth. Proper installation and torque procedures are essential.

Making the Right Choice for Your Goal

To select and apply PTFE gasket sheets correctly, align your choice with the primary demand of the application.

- If your primary focus is sealing aggressive chemicals: Standard virgin PTFE is an excellent choice, but always verify its compatibility with extreme agents like fluorine.

- If your primary focus is a high-purity or sanitary application: Insist on documentation confirming the material is 100% virgin, FDA-compliant PTFE.

- If your primary focus is a high-pressure or temperature-cycling service: Prioritize a filled PTFE material to minimize creep and ensure a stable, long-lasting seal.

Ultimately, a successful seal depends on matching the unique properties of PTFE to the specific demands of your system.

Summary Table:

| Consideration | Key Challenge | Solution / Action |

|---|---|---|

| Creep (Cold Flow) | Material deforms under pressure, leading to seal failure. | Use filled PTFE grades or follow precise torque procedures. |

| Application Grade & Purity | Risk of contamination in sanitary or regulated processes. | Specify 100% virgin, FDA-compliant PTFE for food, pharma, or water. |

| Sheet Thickness Tolerance | Uneven compression causes leaks in large or sensitive flanges. | Source sheets with tight manufacturing tolerances for uniform sealing. |

Need a PTFE Gasket Solution Tailored to Your Application?

At KINTEK, we understand that a reliable seal depends on more than just the material. Our expertise lies in manufacturing precision PTFE components—from gaskets and seals to custom labware—that are engineered to address the critical challenges of creep, purity, and dimensional accuracy.

We serve specialized industries where failure is not an option, including:

- Semiconductor manufacturing

- Medical and pharmaceutical processing

- Laboratory and analytical equipment

- Industrial chemical processing

Let us provide you with a solution that ensures safety, compliance, and performance. Whether you need a prototype for testing or a high-volume order, our custom fabrication capabilities are designed to meet your exact specifications.

Contact KINTEK today for a consultation and let our experts help you achieve a perfect, lasting seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Is a Teflon sheet necessary for all heat press applications? Essential Protection for Consistent Results

- Why is bronze-filled PTFE suitable for high-pressure environments? Achieve Superior Strength & Durability

- Why are PTFE valves used in chemical flow applications? For Unmatched Chemical Inertness and Purity

- What are the key properties of PTFE valves? Ensure Purity, Safety, and Reliability in Demanding Processes

- What tools are recommended for machining PTFE? Achieve Precision Cuts with Sharp, Uncoated Tooling

- How do Teflon bellow mechanical seals enhance equipment efficiency in the pulp and paper industry? Boost Reliability and Cut Costs

- What customization options are available for PTFE sheets? Engineer the Perfect Material for Your Application

- What are some alternative names for PTFE O-rings? Teflon®, TFE, and Polytetrafluoroethylene Explained