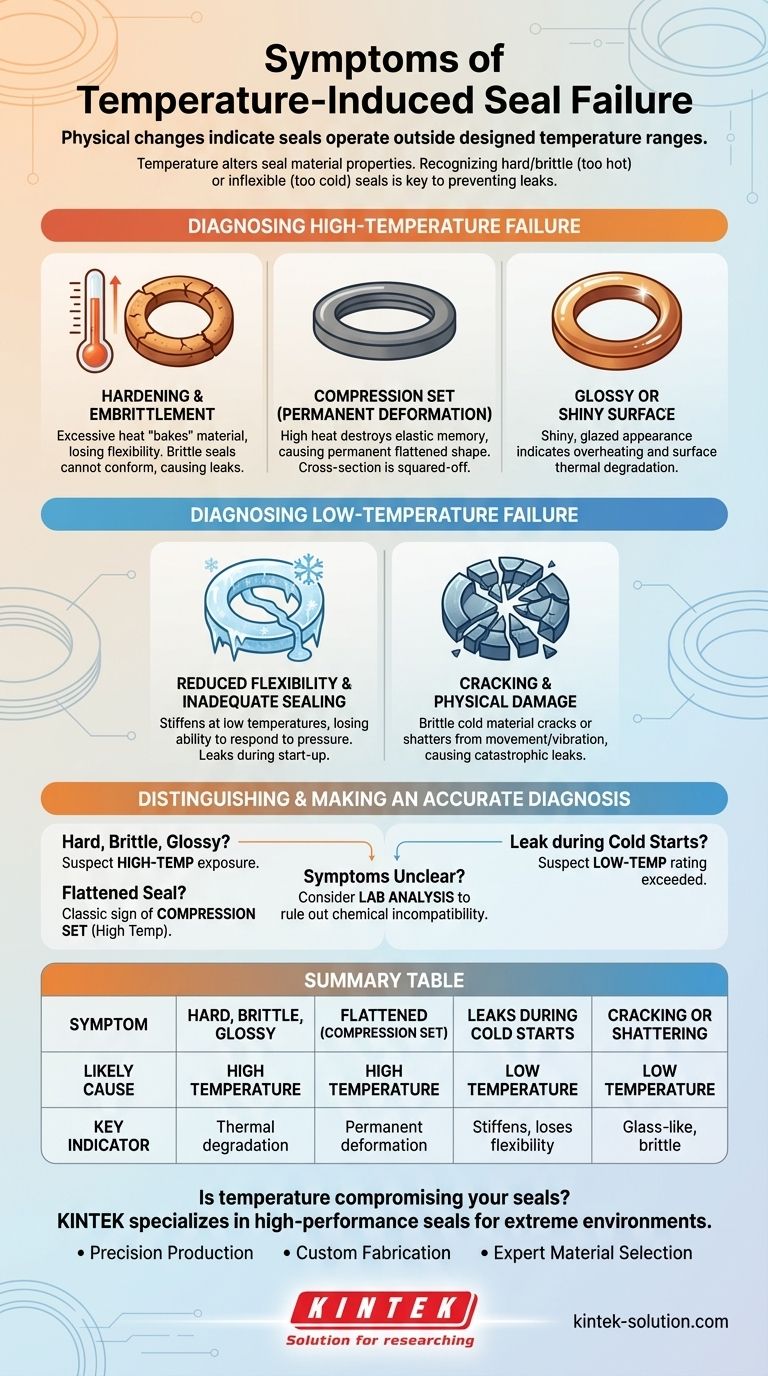

The primary symptoms of temperature-induced seal failure are physical changes to the seal material itself. These include leaks, abnormal or premature wear, permanent deformation (compression set), excessive hardening, and a glossy surface appearance, all of which indicate the seal has operated outside its designed temperature range.

Temperature doesn't just cause a seal to fail; it fundamentally alters the physical properties of the seal's material. Recognizing whether the seal has become hard and brittle (too hot) or lost its flexibility (too cold) is the key to correctly diagnosing and preventing future leaks.

Diagnosing High-Temperature Failure

When a seal operates above its maximum rated temperature, the elastomer material begins to degrade. This thermal degradation is often irreversible and presents with distinct physical symptoms.

Hardening and Embrittlement

Excessive heat effectively "bakes" the seal material. This process drives out the plasticizers that give the elastomer its flexibility, causing it to become hard and brittle. A brittle seal can no longer move and conform to the sealing surfaces, leading to leaks.

Compression Set (Permanent Deformation)

A healthy seal is elastic; it compresses to create a seal and rebounds when the pressure is removed. High temperatures destroy this "elastic memory," causing the seal to take a permanent set in its compressed shape. You will often see a flattened or squared-off cross-section on a seal that has failed due to compression set.

Glossy or Shiny Surface

A shiny, glazed, or glossy appearance on the seal's surface is a clear indicator of overheating. This is a form of thermal degradation where the surface of the material has been fundamentally altered by heat exposure.

Diagnosing Low-Temperature Failure

Operating a seal below its minimum rated temperature is just as damaging as overheating it. The primary issue at low temperatures is the loss of elasticity.

Reduced Flexibility and Inadequate Sealing

As temperatures drop, an elastomer seal will stiffen and lose its ability to respond to pressure and surface imperfections. It may reach its "glass transition" temperature (Tg), where it becomes hard and glass-like. This stiffness creates leak paths, which are often most noticeable during system start-up or pressure fluctuations.

Cracking and Physical Damage

A seal that has become brittle due to cold is highly susceptible to physical damage. Any movement, vibration, or pressure shock can cause the stiffened material to crack or shatter, resulting in a catastrophic leak.

Distinguishing Temperature Failure from Other Causes

It's critical to differentiate temperature-related failure from other common issues. Misdiagnosis can lead to repeated failures even after a seal is replaced.

Misdiagnosing Wear

Abnormal wear can be caused by high temperatures, but it is also a classic symptom of poor lubrication, abrasive fluids, or improper hardware finishing. Always check for these mechanical issues in addition to temperature.

The Role of Chemical Incompatibility

Many symptoms of high-temperature failure—such as hardening, swelling, or material degradation—can also be caused by chemical attack. If the sealed fluid is incompatible with the elastomer, it will break down the material. This effect is often accelerated by high temperatures, making it difficult to isolate a single cause.

Making an Accurate Diagnosis

Use the physical evidence to determine the root cause of the failure and select the appropriate corrective action for your system.

- If you see a hard, brittle, or glossy seal: Suspect high-temperature exposure and verify the system's operating temperature against the seal's material specifications.

- If a leak occurs during cold starts or in low ambient temperatures: Suspect the seal material's low-temperature rating has been exceeded, causing it to lose its required flexibility.

- If you observe a "flattened" seal that no longer rebounds: This is a classic sign of compression set, almost always caused by prolonged high-temperature operation.

- If symptoms are unclear: Consider sending the failed seal and a fluid sample for laboratory analysis to rule out chemical incompatibility before focusing solely on temperature.

Correctly identifying the signs of thermal stress is the first step toward building a more reliable and resilient system.

Summary Table:

| Symptom | Likely Cause | Key Indicator |

|---|---|---|

| Hard, Brittle, Glossy Surface | High Temperature | Thermal degradation from exceeding max temperature |

| Flattened, No Rebound (Compression Set) | High Temperature | Permanent deformation from prolonged heat exposure |

| Leaks During Cold Starts | Low Temperature | Seal stiffens and loses flexibility below its rating |

| Cracking or Shattering | Low Temperature | Material becomes glass-like and brittle |

Is temperature compromising your seals?

If you're experiencing leaks, premature wear, or system downtime due to seal failure, the root cause is often thermal stress. KINTEK specializes in manufacturing high-performance PTFE seals and components designed to withstand extreme temperatures in demanding environments like semiconductor, medical, and laboratory applications.

We provide:

- Precision Production: Consistent quality for reliable performance.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your specific temperature and chemical requirements.

- Expert Material Selection: Ensure your seals operate within their optimal temperature range.

Don't let temperature-induced seal failure disrupt your operations. Contact KINTEK today for a consultation and let our experts help you build a more resilient system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does CNC machining benefit PTFE part fabrication? Achieve Unmatched Precision and Complexity

- What future developments are expected for Teflon O-rings? Advanced Composites & Smarter Designs

- How do PTFE expansion joints contribute to food and beverage production? Ensure Purity and Boost Efficiency

- What temperature range can PTFE Bellows withstand? Operate from -200°C to +260°C

- What is the purpose of PTFE piston guide rings? Prevent Costly Wear in Your Equipment

- What industries benefit from using PTFE rod in bearings and bushings? Enhance Performance in Demanding Environments

- What factors should be considered when choosing PTFE packings? Select the Right Packing for Optimal Sealing

- What are the key properties of PTFE that make it useful in sports equipment? Boost Speed and Durability