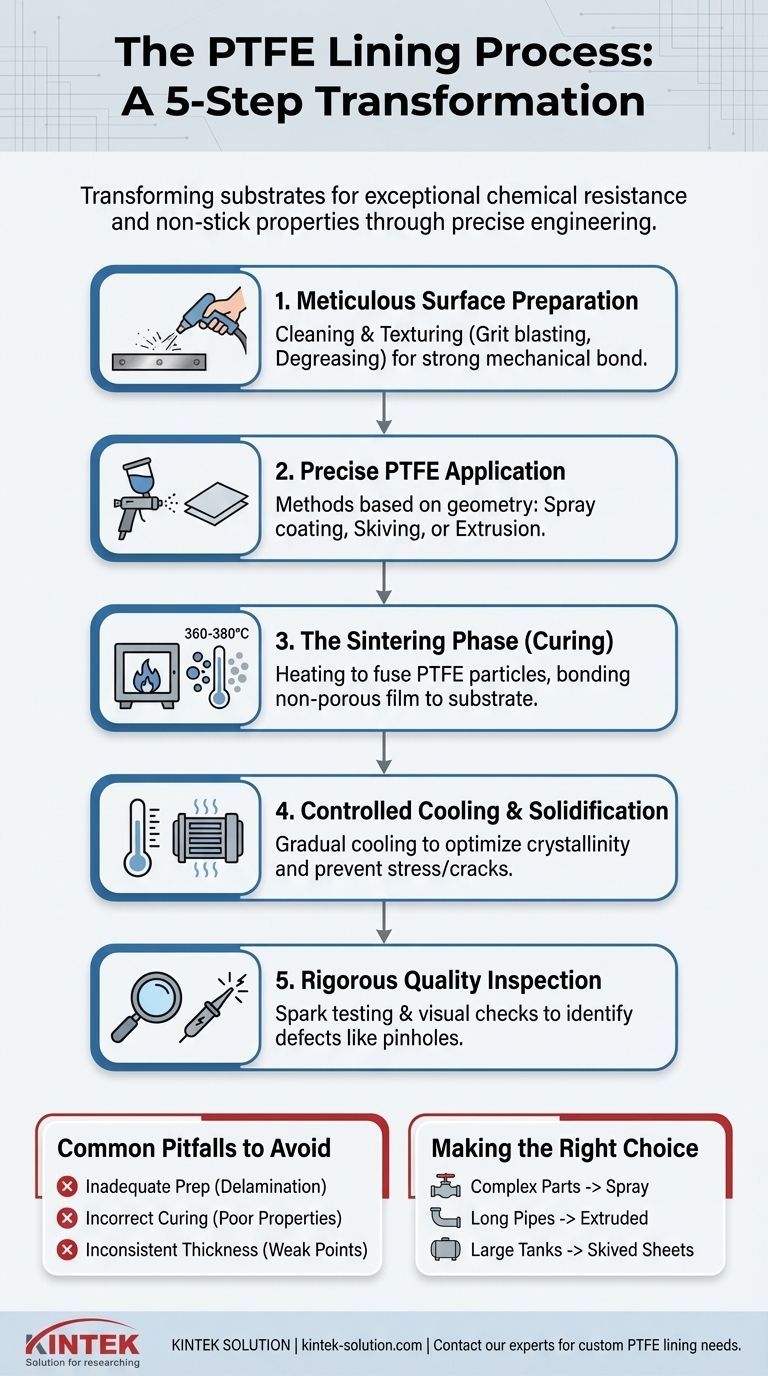

In short, the Polytetrafluoroethylene (PTFE) lining process involves five critical stages: preparing the substrate surface, applying the PTFE material, heating the component to cure and bond the polymer, allowing it to cool and solidify, and performing a final quality inspection. This sequence is designed to transform a standard metal or composite component into one with exceptional chemical resistance and non-stick properties.

The success of a PTFE lining is not merely about applying a coating; it is a controlled engineering process where meticulous surface preparation and precise thermal curing are paramount to achieving a permanent, defect-free bond between the polymer and the substrate.

Deconstructing the Core Lining Process

Each step in the PTFE lining process serves a distinct and vital function. Skipping or poorly executing any stage will compromise the integrity and performance of the final product.

Step 1: Meticulous Surface Preparation

Before any PTFE is applied, the target surface, or substrate, must be impeccably clean and properly textured. This is the foundation for a strong mechanical bond.

Common preparation methods include grit blasting to create a rough surface profile for the PTFE to anchor into, followed by degreasing or chemical cleaning to remove any oils, rust, or contaminants that would prevent adhesion.

Step 2: Precise PTFE Application

With the substrate prepared, the PTFE is applied. The method used depends heavily on the geometry of the part and the required thickness of the lining.

Common techniques include spray coating, where liquid PTFE dispersion is applied in multiple thin layers, or skiving, where a pre-made PTFE sheet is cut and fitted to the interior of a vessel. For pipes, extrusion is often used to create a seamless liner that is inserted into the pipe.

Step 3: The Sintering Phase - Creating the Bond

This is the most critical thermal stage. The lined component is heated in a carefully controlled oven to a temperature above the melting point of PTFE (typically around 360-380°C or 680-716°F).

This process, known as sintering or curing, causes the individual PTFE particles to fuse together into a single, non-porous film. Simultaneously, it forces the molten polymer into the textured profile of the prepared substrate, locking it into place as it cools.

Step 4: Controlled Cooling and Solidification

After sintering, the component must be cooled in a controlled manner. The rate of cooling influences the crystallinity of the PTFE, which in turn affects its physical properties like hardness and permeability.

Improper cooling can introduce stress into the lining, potentially leading to cracks or a weaker bond with the substrate over time.

Step 5: Rigorous Quality Inspection

Finally, every lined component undergoes a thorough inspection. This is a non-destructive process designed to identify any imperfections that could lead to failure in the field.

The most common test is a spark test, where a high-voltage probe is passed over the entire lined surface. Any pinholes, cracks, or areas of insufficient thickness will allow a spark to arc to the metal substrate, immediately identifying a defect. Visual inspection for blisters and uniformity is also performed.

Common Pitfalls to Avoid

Understanding the potential failures highlights the importance of a well-controlled process. The quality of the final product is entirely dependent on the execution of each step.

Inadequate Surface Preparation

This is the most common cause of lining failure. Any residual grease, moisture, or oxidation on the substrate will prevent the PTFE from forming a strong bond, leading to blistering and eventual delamination.

Incorrect Curing Parameters

Under-curing the PTFE results in a porous lining with poor mechanical properties that will not perform as expected. Over-curing can degrade the polymer, making it brittle and compromising its chemical resistance.

Lining Thickness Inconsistencies

An uneven lining, particularly one with thin spots, creates weak points that are prone to chemical attack and mechanical failure. This is why multi-layer spray applications and final spark testing are so crucial for quality assurance.

Making the Right Choice for Your Goal

The specific method and parameters of the PTFE lining process are chosen based on the intended application and the geometry of the component.

- If your primary focus is lining complex equipment like valves or pump housings: A multi-coat spray process is necessary to ensure complete and uniform coverage.

- If your primary focus is protecting long, straight sections of pipe: An extruded or isostatically molded liner offers the most seamless and reliable performance.

- If your primary focus is lining large, simple tanks or vessels: Applying skived PTFE sheets can be an effective and economical solution.

Ultimately, a properly executed PTFE lining process creates a robust, composite material that leverages the strength of the substrate and the unique protective properties of the polymer.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Surface Preparation | Grit blasting & degreasing | Creates a clean, textured surface for strong mechanical bonding. |

| 2. PTFE Application | Spray coating, skiving, or extrusion | Applies the polymer evenly based on the component's geometry. |

| 3. Sintering | Heating to 360-380°C (680-716°F) | Fuses PTFE particles and bonds the lining to the substrate. |

| 4. Controlled Cooling | Gradual temperature reduction | Solidifies the PTFE to achieve optimal physical properties. |

| 5. Quality Inspection | Spark testing & visual check | Identifies defects like pinholes or cracks to ensure reliability. |

Need a flawlessly lined PTFE component for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom liners, seals, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production process, from prototypes to high-volume orders, ensures a permanent, defect-free bond that delivers exceptional chemical resistance and non-stick properties.

Let us provide the durable solution your project requires. Contact our experts today to discuss your custom PTFE lining needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability