The most significant mechanical characteristics of PTFE are its exceptionally low coefficient of friction and high flexibility. These properties are balanced by its relative softness, moderate tensile strength, and a notable tendency to deform under sustained load, a phenomenon known as creep. This unique combination makes it an outstanding material for specific applications but unsuitable for others.

PTFE should not be viewed as a high-strength structural plastic. Instead, its primary value lies in its unique ability to solve problems related to friction, sealing, and chemical resistance, provided its mechanical limitations are properly managed.

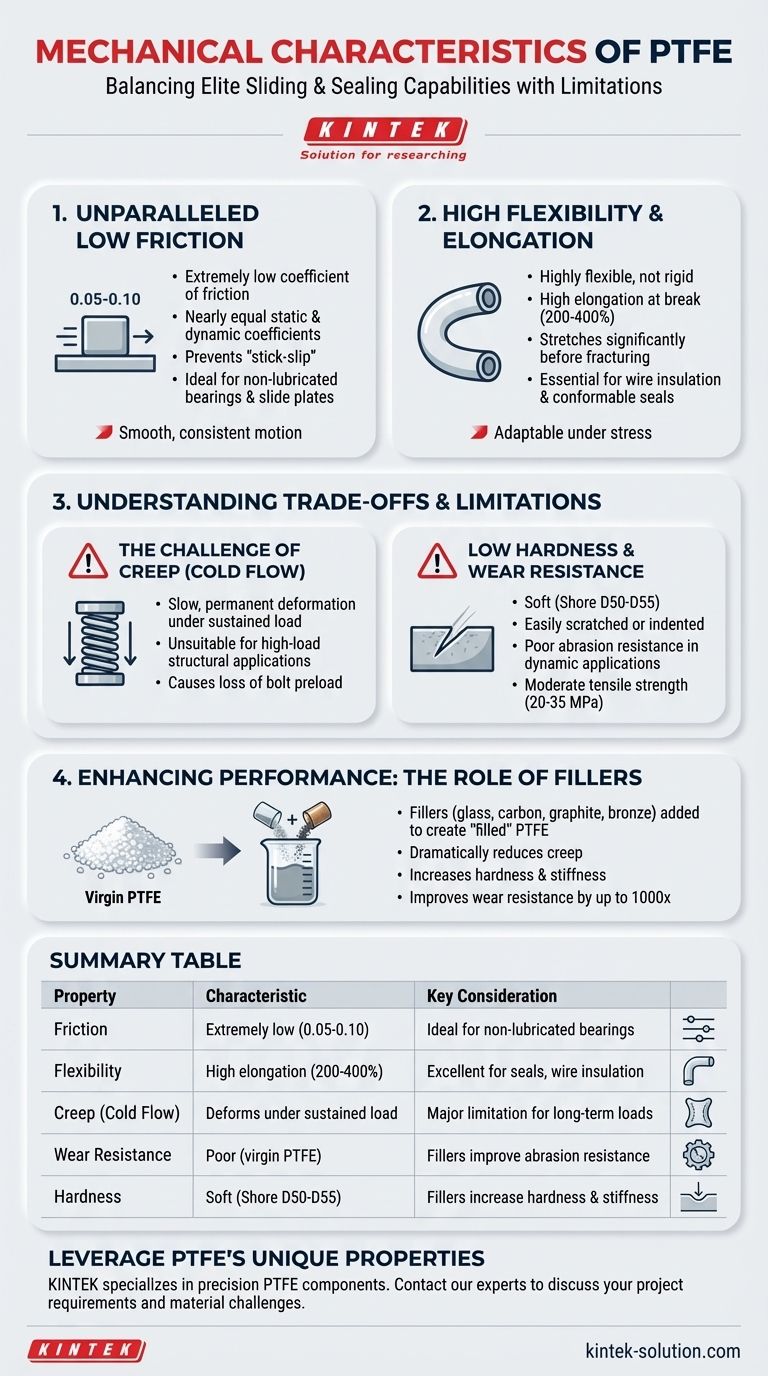

The Defining Mechanical Traits of PTFE

To select PTFE for an application, you must understand how its core properties interact. It is a material of useful contradictions: soft yet tough, flexible yet strong in compression.

Unparalleled Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, typically between 0.05 and 0.10. This is its most famous characteristic.

Critically, its static and dynamic friction coefficients are nearly equal. This prevents the "stick-slip" phenomenon common in other materials, allowing for exceptionally smooth and consistent motion from a complete stop.

This property makes it the default choice for high-performance, non-lubricated bearings, slide plates, and low-friction surface coatings.

High Flexibility and Elongation

PTFE is not rigid; it is a highly flexible material. It can bend easily and has a very high elongation at break, often between 200% and 400%.

This means it can stretch to several times its original length before fracturing. This flexibility is essential for applications like wire insulation, flexible tubing, and creating conformable seals.

Good Compressive Strength and Plastic Memory

While not exceptionally strong in tension, PTFE performs well under compression. It can be deformed under a load to create an extremely effective seal against a flange or surface.

It also exhibits plastic memory, meaning it has a tendency to return to its original shape after a deforming force is removed. This helps a seal maintain its force over time through thermal cycles.

Excellent Impact Resistance

Despite its softness, PTFE has good toughness and impact strength. It can absorb sudden shocks and impacts without fracturing, which is not always the case for harder, more brittle plastics.

Understanding the Trade-offs and Limitations

The benefits of PTFE come with significant mechanical trade-offs. Acknowledging these weaknesses is the key to using the material successfully.

The Challenge of Creep (Cold Flow)

This is PTFE's most critical mechanical weakness. Creep is the tendency of the material to slowly and permanently deform when subjected to a continuous load, even at room temperature.

For example, a PTFE washer under a constantly torqued bolt will slowly flatten over time, causing the bolt to lose its preload. This makes virgin PTFE unsuitable for high-load structural applications.

Low Hardness and Stiffness

PTFE is a relatively soft material, typically measuring between D50 and D55 on the Shore hardness scale. It can be easily scratched or indented.

It also has a very low tensile modulus (0.4-0.5 GPa), meaning it is not stiff. This contributes to its flexibility but also its tendency to deform under load.

Moderate Tensile Strength and Low Wear Resistance

PTFE has a moderate tensile strength of around 20-35 MPa. It is not designed to handle high-tension loads.

Furthermore, its low hardness results in poor abrasion resistance. When used in dynamic applications against a rough surface, virgin PTFE will wear away relatively quickly.

The Role of Fillers: Enhancing PTFE's Performance

To overcome its inherent weaknesses, PTFE is often blended with filler materials like glass, carbon, graphite, or bronze. This creates a "filled" or "compounded" PTFE.

Adding fillers dramatically reduces creep, increases hardness and stiffness, and can improve wear resistance by a factor of 1000 or more. While fillers may slightly increase the coefficient of friction, the resulting compound offers a far better balance of properties for demanding mechanical applications.

Making the Right Choice for Your Application

Your material choice depends entirely on the primary demand of your design.

- If your primary focus is the lowest possible friction for sliding: Virgin (unfilled) PTFE is an excellent choice, especially for low-load bearings or slide surfaces.

- If your primary focus is creating a conformable, chemically resistant seal: Virgin PTFE is ideal, but you must account for potential creep in long-term, high-pressure static seals.

- If your primary focus is wear resistance, stiffness, or stability under load: A filled PTFE compound is almost certainly the correct choice over the virgin material.

Ultimately, understanding PTFE's mechanical profile is about leveraging its elite sliding and sealing capabilities while respecting its limitations in hardness and creep.

Summary Table:

| Key Property | Characteristic | Key Consideration |

|---|---|---|

| Friction | Extremely low (0.05-0.10) | Ideal for non-lubricated bearings and sliding surfaces. |

| Flexibility | High elongation (200-400%) | Excellent for seals, wire insulation, and flexible tubing. |

| Creep (Cold Flow) | Deforms under sustained load | A major limitation for long-term, high-load structural applications. |

| Wear Resistance | Poor (virgin PTFE) | Fillers (glass, carbon) dramatically improve abrasion resistance. |

| Hardness | Soft (Shore D50-D55) | Easily scratched; fillers increase hardness and stiffness. |

Leverage PTFE's Unique Properties for Your Application

PTFE's combination of low friction, chemical resistance, and flexibility makes it ideal for critical components in the semiconductor, medical, laboratory, and industrial sectors. However, successfully implementing it requires a deep understanding of its mechanical trade-offs, like creep.

KINTEK specializes in manufacturing precision PTFE components—from custom seals and liners to complex labware. We help you navigate the choice between virgin and filled PTFE compounds to ensure optimal performance, whether you need a prototype or a high-volume production run.

Let's discuss your project requirements and material challenges. Contact our experts today to get a quote and see how our precision fabrication can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique characteristics of PTFE? Leverage Extreme Chemical & Thermal Resistance

- How does PTFE compare to Polyethylene (PE) in terms of chemical and temperature resistance? Choose the Right Polymer for Extreme Conditions

- What industries commonly use RPTFE and for what purposes? Enhance Durability in High-Load Applications

- What substances can affect the carbon-fluorine bonds in PTFE? Uncover the Limits of its Chemical Inertness

- What is the specific gravity range of PTFE? A Key Indicator of Its High-Performance Properties

- What are the key properties that make Teflon widely applicable? Unlock Unmatched Chemical & Thermal Resistance

- What are the common quality control methods for PTFE products? Ensure Performance and Reliability

- What makes PTFE resistant to UV and weathering? The Science Behind its Inherent, Lasting Durability