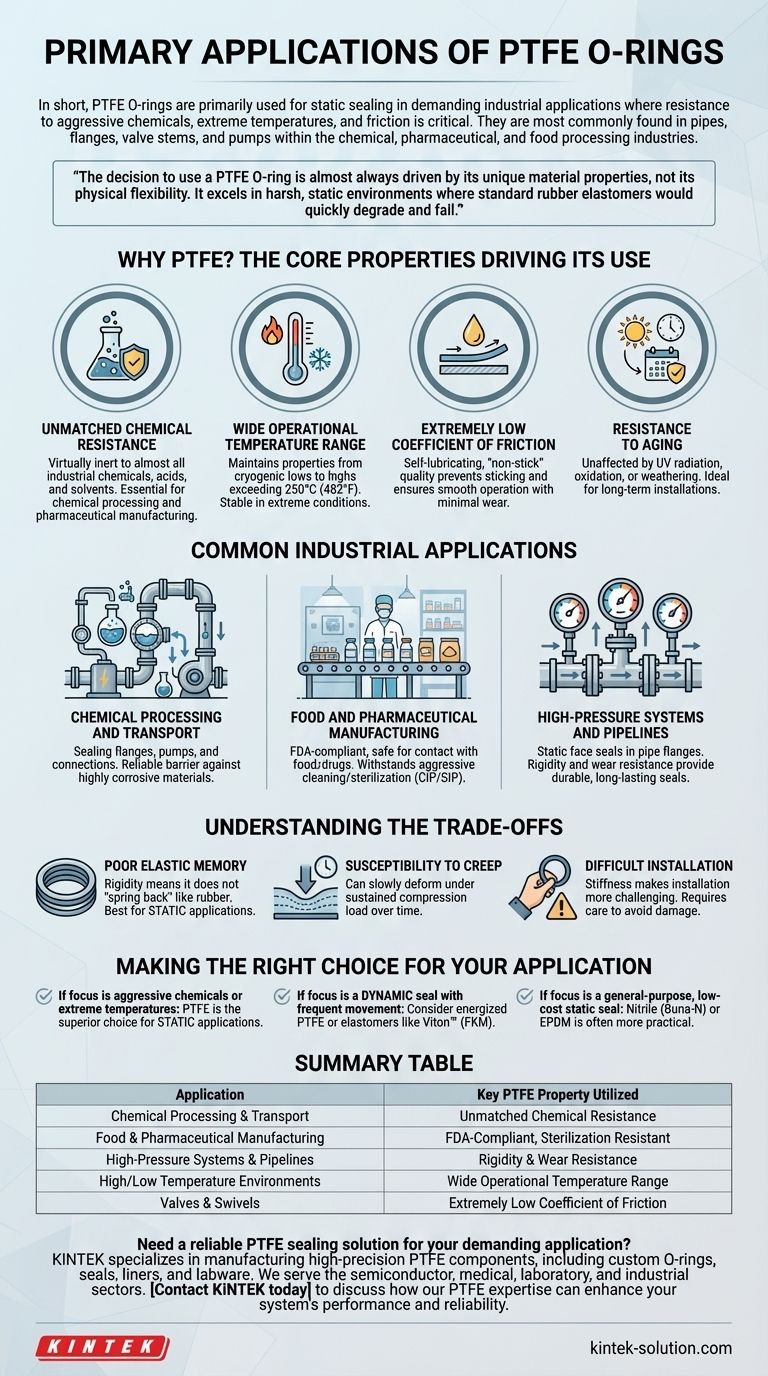

In short, PTFE O-rings are primarily used for static sealing in demanding industrial applications where resistance to aggressive chemicals, extreme temperatures, and friction is critical. They are most commonly found in pipes, flanges, valve stems, and pumps within the chemical, pharmaceutical, and food processing industries.

The decision to use a PTFE O-ring is almost always driven by its unique material properties, not its physical flexibility. It excels in harsh, static environments where standard rubber elastomers would quickly degrade and fail.

Why PTFE? The Core Properties Driving Its Use

Understanding the fundamental characteristics of Polytetrafluoroethylene (PTFE) is key to knowing where and why it is applied. Its selection is a deliberate engineering choice based on performance under stress.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the default choice for sealing systems that handle aggressive or corrosive media.

This property is why PTFE O-rings are essential in chemical processing equipment and pharmaceutical manufacturing lines where seal integrity cannot be compromised.

Wide Operational Temperature Range

PTFE maintains its properties across a vast temperature spectrum, from cryogenic lows to highs exceeding 250°C (482°F).

Where a standard elastomer O-ring would become brittle in the cold or degrade in the heat, PTFE provides a stable and reliable seal.

Extremely Low Coefficient of Friction

Often marketed under the brand name Teflon®, PTFE has one of the lowest friction coefficients of any solid material. This self-lubricating, "non-stick" quality is vital.

In applications like valve stems or swivels, this low-friction surface prevents sticking and ensures smooth operation with minimal wear over time.

Resistance to Aging

Unlike many rubber compounds, PTFE is unaffected by UV radiation, oxidation, or weathering. This exceptional durability makes it ideal for long-term installations, especially in exposed environments like pipeline flanges.

Common Industrial Applications

Based on its properties, PTFE is deployed in several key sectors where performance is non-negotiable.

Chemical Processing and Transport

The primary application for PTFE O-rings is sealing flanges, pumps, and connections in the chemical industry. They provide a reliable barrier against highly corrosive materials that would destroy other seals.

Food and Pharmaceutical Manufacturing

PTFE is FDA-compliant, making it safe for contact with food and drugs. It can also withstand the aggressive cleaning and sterilization processes (CIP/SIP) common in these industries without degrading or leaching.

High-Pressure Systems and Pipelines

In static face seals, such as those in pipe flanges or equipment covers, PTFE's rigidity and resistance to wear from high-flow media provide a durable, long-lasting seal.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its limitations are as important to understand as its strengths.

Poor Elastic Memory

The most significant drawback of PTFE is its rigidity. Unlike a rubber O-ring, it is not truly elastic and will not "spring back" to its original shape after being compressed.

Because of this, it is almost exclusively recommended for static applications where the seal is compressed and left in place. It performs poorly in dynamic applications with reciprocating or rotating parts.

Susceptibility to Creep

Under a sustained load (compression), PTFE can be prone to "creep" or "cold flow," meaning it can slowly deform over time. This must be accounted for in the engineering design of the groove and connecting flanges.

Difficult Installation

The material's stiffness can make installation more challenging than with a flexible rubber O-ring. Care must be taken to avoid scratching or damaging the seal surface during assembly, which could create a leak path.

Making the Right Choice for Your Application

Selecting the correct sealing material requires a clear understanding of your operational goals.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: PTFE is the superior choice for static applications where other materials will fail.

- If your primary focus is a dynamic seal with frequent movement: A standard PTFE O-ring is a poor fit; consider an energized PTFE seal or a more suitable elastomer like Viton™ (FKM) or silicone.

- If your primary focus is a general-purpose, low-cost static seal: A standard nitrile (Buna-N) or EPDM rubber O-ring is often more practical and cost-effective for non-demanding environments.

Ultimately, selecting a PTFE O-ring is a strategic decision for applications where material resilience is more critical than mechanical flexibility.

Summary Table:

| Application | Key PTFE Property Utilized |

|---|---|

| Chemical Processing & Transport | Unmatched Chemical Resistance |

| Food & Pharmaceutical Manufacturing | FDA-Compliant, Sterilization Resistant |

| High-Pressure Systems & Pipelines | Rigidity & Wear Resistance |

| High/Low Temperature Environments | Wide Operational Temperature Range |

| Valves & Swivels | Extremely Low Coefficient of Friction |

Need a reliable PTFE sealing solution for your demanding application? KINTEK specializes in manufacturing high-precision PTFE components, including custom O-rings, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your components withstand aggressive chemicals, extreme temperatures, and high-pressure environments. Our expertise in custom fabrication—from prototypes to high-volume orders—guarantees a perfect fit for your unique requirements. Contact KINTEK today to discuss how our PTFE expertise can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the different types of PTFE seals? Choose the Right Seal for Your Application

- How is a PTFE sheet attached to metal surfaces in chemical tanks? A Guide to Specialized Adhesive Bonding

- What is the purpose of using MoS2 (Moly) as a filler in PTFE? Enhance Wear Resistance & Load Capacity

- What are the key performance parameters of PTFE gland packings? Maximize Seal Performance and Reliability

- How is surface preparation performed for PTFE coating application? Achieve Unbreakable Adhesion for Your Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are O-rings and their primary function? The Key to Leak-Free Sealing in Any System

- Which industries commonly use PTFE Expansion Bellows? Solve Your Critical Chemical and Purity Challenges