Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by a unique combination of physical properties. It possesses an extremely high melting point around 327°C, near-universal chemical inertness, and one of the lowest coefficients of friction of any solid. Combined with its high density of 2.2 g/cm³, excellent electrical insulation, and hydrophobicity, these characteristics make it exceptionally versatile.

PTFE's value lies not in a single property, but in the rare synergy of its thermal stability, chemical inertness, and non-stick surface, making it one of the most durable and reliable plastics for extreme environments.

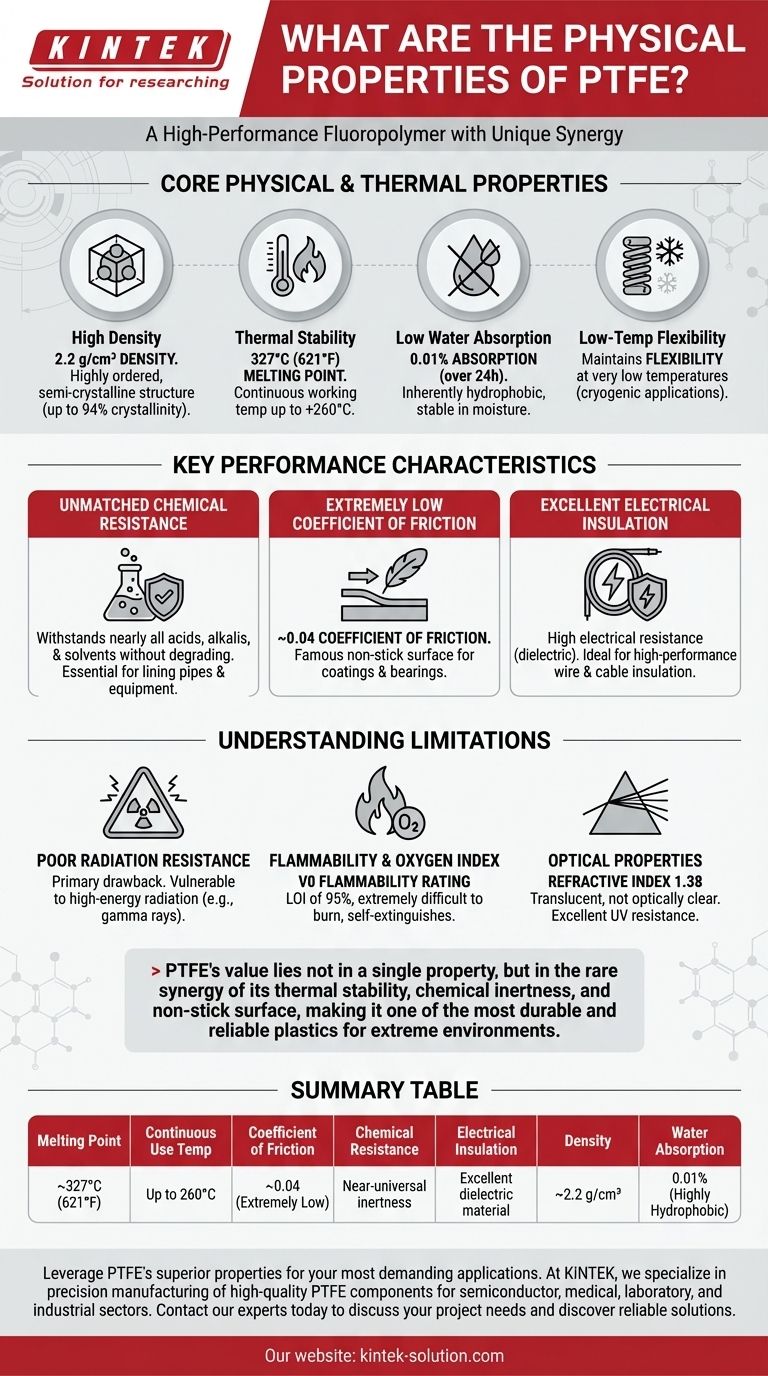

Core Physical and Thermal Properties

The foundational characteristics of PTFE set it apart from conventional plastics, making it suitable for demanding conditions.

High Density and Crystallinity

PTFE is one of the densest plastics, with a density around 2.2 g/cm³. This density is a result of its highly ordered, semi-crystalline structure, which can reach up to 94% crystallinity.

Exceptional Thermal Stability

PTFE exhibits a very high melting point of approximately 327°C (621°F). More importantly for practical use, it has a continuous working temperature of up to +260°C, the highest among all fluoroplastics.

Low Water Absorption

The material is inherently hydrophobic, meaning it repels water. Its water absorption is extremely low, measured at just 0.01% over a 24-hour period, ensuring its properties remain stable in moist environments.

Flexibility at Low Temperatures

Despite its robustness at high temperatures, PTFE maintains a high degree of flexibility even at very low temperatures, a critical property for cryogenic applications.

Key Performance Characteristics

These properties are the reason PTFE is specified for so many critical applications, from chemical processing to electronics.

Unmatched Chemical Resistance

PTFE is renowned for its extreme chemical inertness. It can withstand nearly all acids, alkalis, and solvents without degrading, even at elevated temperatures. This makes it an essential material for lining pipes, vessels, and equipment in chemical manufacturing.

Extremely Low Coefficient of Friction

With a coefficient of friction around 0.04, PTFE has one of the lowest values of any known solid material. This property is responsible for its famous non-stick surface, making it ideal for coatings, bearings, and other low-friction applications.

Excellent Electrical Insulation

PTFE possesses very high electrical resistance, making it an excellent dielectric material. This property is leveraged for high-performance wire and cable insulation where signal integrity and safety are paramount.

Understanding the Limitations

No material is perfect. Acknowledging PTFE's specific limitations is crucial for proper application and avoiding failure.

Poor Radiation Resistance

The primary drawback of PTFE is its poor resistance to high-energy radiation, such as gamma rays. This type of radiation can cause the polymer chains to break down, compromising its structural integrity.

Flammability and Oxygen Index

While PTFE has a top flammability rating of V0 (meaning it self-extinguishes after being ignited), its behavior is best understood by its Limiting Oxygen Index (LOI). With an LOI of 95%, it requires an atmosphere of 95% oxygen to sustain combustion, making it extremely difficult to burn.

Optical Properties

PTFE is not typically used for its optical qualities. It has a refractive index of 1.38 and can be made translucent, but it is not optically clear like polycarbonate or acrylic. It also shows excellent resistance to UV radiation.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on whether its unique strengths align with your primary engineering challenge.

- If your primary focus is withstanding harsh chemicals and high temperatures: PTFE's chemical inertness and a continuous working temperature of up to 260°C make it the default choice.

- If your primary focus is creating a low-friction or non-stick surface: Its ultra-low coefficient of friction is unparalleled for applications from industrial bearings to advanced coatings.

- If your primary focus is high-performance electrical insulation: PTFE's outstanding dielectric properties provide reliable insulation for the most critical wiring applications.

Ultimately, understanding these core properties empowers you to leverage PTFE's strengths precisely where they matter most.

Summary Table:

| Property | Value / Description |

|---|---|

| Melting Point | ~327°C (621°F) |

| Continuous Use Temp | Up to 260°C |

| Coefficient of Friction | ~0.04 (Extremely Low) |

| Chemical Resistance | Near-universal inertness |

| Electrical Insulation | Excellent dielectric material |

| Density | ~2.2 g/cm³ |

| Water Absorption | 0.01% (Highly Hydrophobic) |

Leverage PTFE's superior properties for your most demanding applications. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components meet exact specifications for performance and durability. Contact our experts today to discuss your project needs and discover how KINTEK can provide the reliable PTFE solutions you require.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to environmental benefits? Durability, Efficiency, and Contamination Prevention

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity