At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. Its performance is defined by an exceptionally low coefficient of friction—the lowest of any solid material—coupled with near-universal chemical inertness and stability across a vast temperature range. These remarkable characteristics stem from its unique molecular structure, making it a go-to solution for some of the most demanding engineering challenges.

PTFE is best understood as a "problem-solver" material for applications where friction, chemical attack, or temperature would cause conventional materials to fail. Its defining strength—an incredibly stable and non-reactive surface—is also the source of its primary weakness: difficulty in bonding to other substrates.

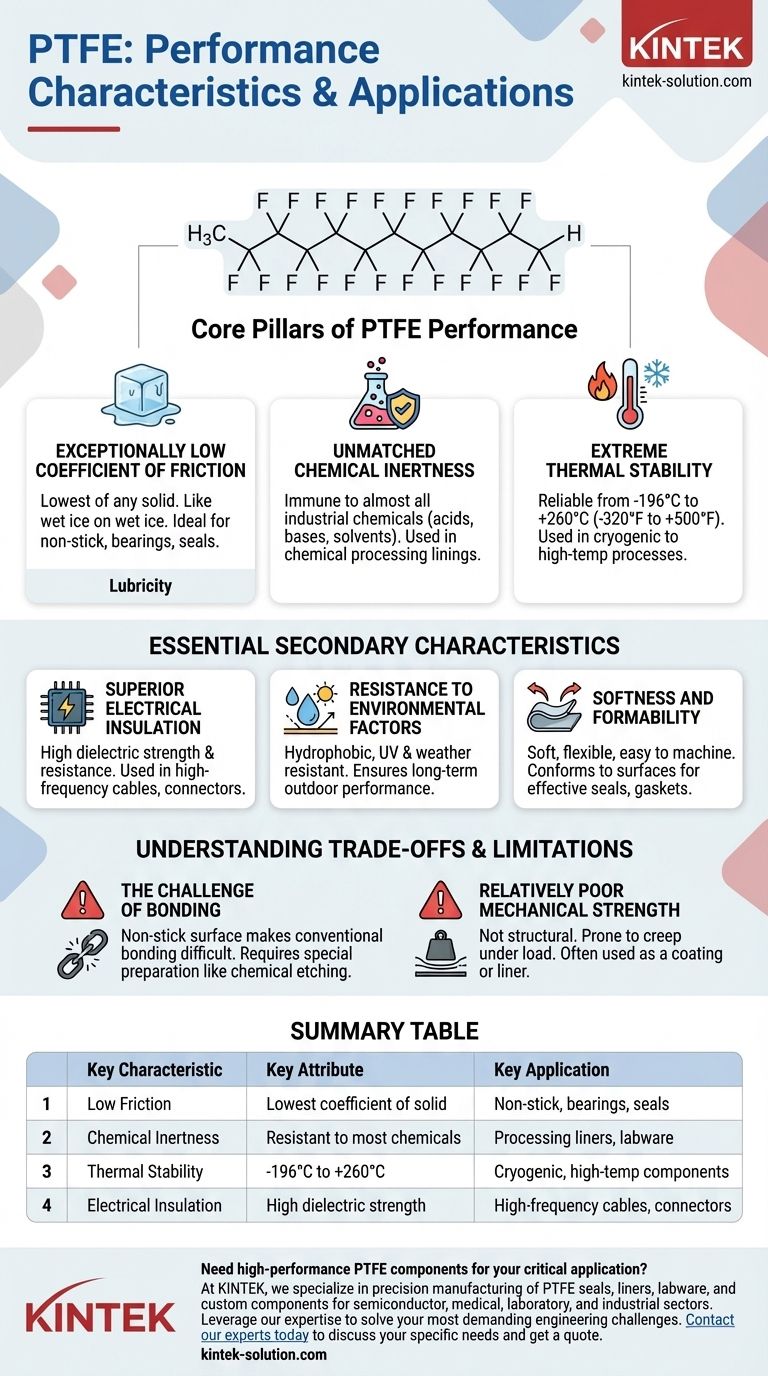

The Core Pillars of PTFE Performance

The defining properties of PTFE all originate from its molecular structure: a long chain of carbon atoms completely shielded by a sheath of fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry, which is the key to its stability.

Exceptionally Low Coefficient of Friction

PTFE exhibits the lowest coefficient of friction of any known solid material. It is often compared to the friction of wet ice on wet ice.

This property, known as lubricity, means surfaces can slide against it with minimal resistance. This makes it an ideal material for non-stick coatings, self-lubricating bearings, and low-friction seals.

Unmatched Chemical Inertness

The strong and stable carbon-fluorine bonds make the PTFE molecule nearly immune to chemical attack.

It is inert to almost all industrial chemicals, including concentrated acids, bases, and organic solvents. This makes it an essential material for lining pipes, tanks, and vessels in the chemical processing industry.

Extreme Thermal Stability

PTFE performs reliably across an incredibly wide service temperature range, typically from -196°C to +260°C (-320°F to +500°F).

This allows it to be used in applications ranging from cryogenic equipment to high-temperature industrial processes without degrading or losing its key properties.

Essential Secondary Characteristics

Beyond the three primary pillars, several other characteristics make PTFE uniquely versatile for specialized applications.

Superior Electrical Insulation

PTFE has a very high dielectric strength and high electrical resistance, making it an excellent electrical insulator.

Its properties are stable across a wide range of frequencies, which is why it is frequently used in high-performance cables, connectors, and circuit boards for radio frequency applications.

Resistance to Environmental Factors

This material is hydrophobic, meaning it repels water and does not absorb moisture.

Furthermore, it is completely resistant to damage from UV radiation and weathering. This combination ensures long-term performance and stability in outdoor or environmentally exposed applications.

Softness and Formability

Despite its robustness in extreme environments, PTFE is a relatively soft and flexible material. It can be easily machined and formed into complex shapes.

This softness allows it to conform to irregular surfaces, making it an excellent choice for creating highly effective seals and gaskets.

Understanding the Trade-offs and Limitations

No material is perfect, and understanding PTFE's limitations is critical for successful application. Its greatest strengths are directly linked to its most significant challenges.

The Challenge of Bonding

The same non-stick, low-energy surface that makes PTFE so valuable also makes it extremely difficult to bond to other materials using conventional adhesives.

Special surface preparation techniques, such as chemical etching, are often required to create a bondable surface, adding complexity and cost to the manufacturing process.

Relatively Poor Mechanical Strength

While PTFE has good flexural strength, it is not a structural plastic. It is soft and has a tendency to creep, or deform over time when subjected to a constant load.

For applications requiring high tensile strength or structural rigidity, PTFE is often used as a coating or liner on a stronger substrate material rather than as a standalone component.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on whether its unique advantages solve your primary engineering challenge.

- If your primary focus is minimizing friction: PTFE is the definitive choice for non-stick surfaces, bearings, and seals where lubricity is paramount.

- If your primary focus is handling corrosive materials: Its near-total chemical inertness makes it the safest and most reliable option for components in chemical processing.

- If your primary focus is high-performance insulation: Its excellent dielectric properties are ideal for demanding electrical and high-frequency applications.

- If your primary focus is structural integrity under load: PTFE is likely unsuitable on its own and should only be considered as a performance-enhancing coating or liner.

Ultimately, you choose PTFE when performance and reliability in an extreme environment are non-negotiable.

Summary Table:

| Key Characteristic | Key Attribute | Key Application |

|---|---|---|

| Low Friction | Lowest coefficient of friction of any solid | Non-stick coatings, bearings, seals |

| Chemical Inertness | Resistant to almost all industrial chemicals | Chemical processing liners, labware |

| Thermal Stability | Service range: -196°C to +260°C | Cryogenic to high-temperature components |

| Electrical Insulation | High dielectric strength | High-frequency cables, connectors |

Need high-performance PTFE components for your critical application?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. We understand that your projects in the semiconductor, medical, laboratory, and industrial sectors demand materials that deliver extreme chemical resistance, superior lubricity, and unwavering thermal stability.

Leverage our expertise in custom fabrication—from prototypes to high-volume orders—to solve your most demanding engineering challenges. Let us provide the reliable PTFE solutions your application requires.

Contact our experts today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers