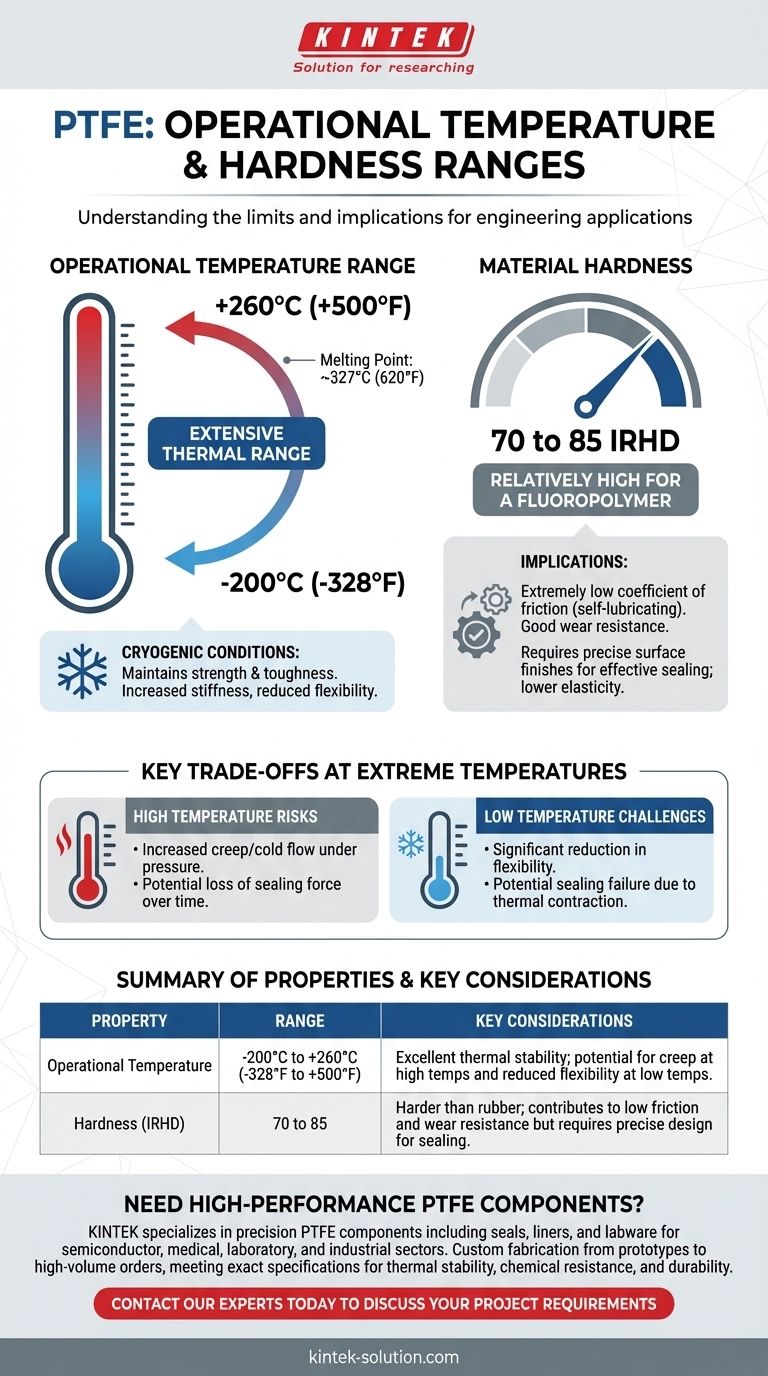

Polytetrafluoroethylene (PTFE) operates effectively across one of the widest thermal ranges of any polymer, generally from -200°C to +260°C (-328°F to +500°F). Its material hardness is relatively high for a fluoropolymer, typically falling between 70 and 85 IRHD (International Rubber Hardness Degrees).

While the numbers provide a starting point, the true measure of PTFE's suitability lies in understanding how its mechanical properties shift at these temperature extremes. The material doesn't simply fail at its limits; it changes, and this change is the critical factor for any engineering design.

Deconstructing the Temperature Range

The exceptionally broad operating temperature of PTFE is its defining characteristic. However, the upper and lower limits are not arbitrary cutoffs but represent practical boundaries where its properties remain predictable and useful for most applications.

The Upper Limit: Approaching Thermal Decomposition

The commonly cited upper service limit for PTFE is 260°C (500°F). This is a conservative figure for continuous operation where the material retains its excellent chemical resistance and low-friction characteristics.

While PTFE's actual melting point is significantly higher at around 327°C (620°F), its mechanical properties like compressive strength and wear resistance begin to degrade as it approaches this temperature. Sticking to the 260°C limit ensures long-term stability under load.

The Lower Limit: Performance in Cryogenic Conditions

At the other end of the spectrum, PTFE maintains high strength and toughness down to cryogenic temperatures. It is commonly used at -200°C (-328°F) and can even function at temperatures as low as -268°C (5°K).

The key change at these low temperatures is a reduction in flexibility. While it does not become brittle like many other polymers, its increased stiffness must be accounted for in any design, especially for sealing or dynamic applications.

Why Do Sources Quote Different Ranges?

You may see more conservative ranges, such as -30°C to +200°C, or specific ratings for components like O-rings. These variations often reflect application-specific testing, the inclusion of fillers that modify properties, or the establishment of a wider safety margin for a particular use case. The -200°C to +260°C range remains the standard for pure, virgin PTFE.

Understanding Hardness and Its Implications

The hardness of a material is crucial for determining its suitability for applications involving sealing, friction, and wear.

The 70-85 IRHD Range

PTFE's hardness of 70 to 85 IRHD places it in the category of a fairly hard plastic. For comparison, a typical rubber O-ring might be around 70 Shore A, which is a softer scale.

This relative hardness contributes directly to PTFE's extremely low coefficient of friction (making it self-lubricating) and good wear resistance.

Hardness vs. Sealing Ability

The trade-off for this hardness is lower elasticity compared to traditional rubber elastomers. This means that for a PTFE seal to be effective, it requires more precise surface finishes and may need a mechanical energizer (like a spring) to maintain sealing force, especially in low-pressure or low-temperature conditions.

Key Trade-offs at Temperature Extremes

No material is perfect under all conditions. Understanding the compromises at the edges of PTFE's operating range is essential for reliable design.

The Risk of High Temperatures

As PTFE nears its 260°C limit, its tendency to creep (also known as cold flow) under pressure increases. For components under a constant load, like a gasket, this can lead to a loss of sealing pressure over time.

The Challenge of Low Temperatures

As noted, the primary challenge at cryogenic temperatures is the loss of flexibility. A PTFE O-ring that seals perfectly at room temperature may not be elastic enough to maintain that seal if the hardware contracts significantly during a thermal cycle to -200°C.

Matching PTFE's Properties to Your Application

Choosing a material requires aligning its properties with the primary demands of the application.

- If your primary focus is static sealing in high-heat or chemical environments: PTFE is an excellent choice, as its thermal and chemical stability is paramount and a loss of flexibility is less critical.

- If your primary focus is dynamic sealing across a wide temperature range: Carefully consider the design, as PTFE's stiffness at low temperatures and potential for creep at high temperatures will impact long-term performance.

- If your primary focus is components for cryogenic systems: PTFE's remarkable toughness at extreme cold is a major advantage, but your design must accommodate its reduced elasticity to function reliably.

By understanding how temperature impacts its core mechanical properties, you can confidently leverage PTFE's remarkable stability for your specific engineering challenge.

Summary Table:

| Property | Range | Key Considerations |

|---|---|---|

| Operational Temperature | -200°C to +260°C (-328°F to +500°F) | Excellent thermal stability; potential for creep at high temps and reduced flexibility at low temps. |

| Hardness (IRHD) | 70 to 85 | Harder than rubber; contributes to low friction and wear resistance but requires precise design for sealing. |

Need High-Performance PTFE Components for Demanding Applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand how temperature and hardness affect performance in real-world applications.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for thermal stability, chemical resistance, and durability.

Contact our experts today to discuss your project requirements and leverage our expertise in advanced polymer solutions.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- How does PTFE's molecular structure contribute to its non-stick properties? The Science Behind Its Slick Surface

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What are the different types of Teflon available? A Guide to PTFE, FEP, PFA, and More

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions