In short, PTFE O-rings are defined by a unique combination of properties: exceptionally low friction, outstanding chemical and thermal resistance, but with comparatively low mechanical strength and a tendency to permanently deform under pressure. While not as robust as many other plastics, their specialized characteristics make them indispensable for specific sealing applications.

PTFE is a high-performance specialist, not a general-purpose workhorse. Its primary value comes from its extreme chemical inertness and low-friction surface, but these benefits come with the critical trade-off of lower mechanical strength and a susceptibility to "creep."

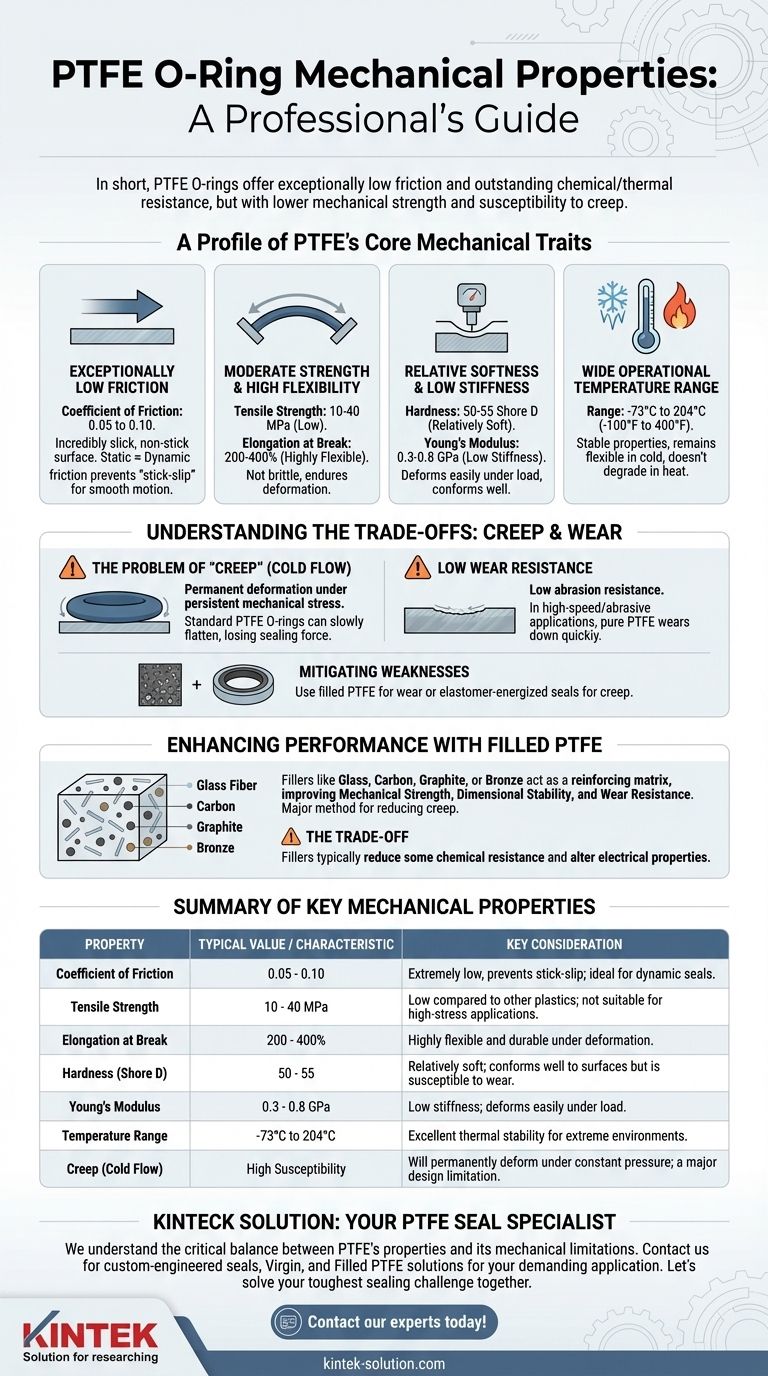

A Profile of PTFE's Core Mechanical Traits

Understanding a PTFE O-ring requires looking at its properties not in isolation, but as a complete profile. It excels in some areas and shows distinct limitations in others.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, typically ranging from 0.05 to 0.10. This gives it an incredibly slick, non-stick surface.

Crucially, its static (breakaway) friction is nearly identical to its dynamic (sliding) friction. This prevents the "stick-slip" phenomenon common in other materials, ensuring smooth, consistent motion in dynamic sealing applications.

Moderate Strength and High Flexibility

Compared to other engineering plastics, PTFE has a relatively low tensile strength, generally between 10 and 40 MPa.

However, it is not brittle. With a very high elongation at break of 200-400%, it is highly flexible and can endure significant deformation before fracturing, contributing to its overall durability.

Relative Softness and Low Stiffness

PTFE is a relatively soft material, with a hardness of about 50-55 on the Shore D scale.

Its low stiffness, reflected by a low Young's Modulus of 0.3-0.8 GPa, means it deforms easily under load. This allows it to conform well to sealing surfaces but also makes it vulnerable to other issues.

Wide Operational Temperature Range

A key mechanical advantage of PTFE is the stability of its properties across a very broad temperature range, from approximately -73°C to 204°C (-100°F to 400°F). It remains flexible at cryogenic temperatures and does not degrade at high heat, unlike many elastomers.

Understanding the Trade-offs: Creep and Wear

The primary challenges with using PTFE O-rings stem directly from its mechanical weaknesses. Ignoring these can lead to seal failure.

The Problem of "Creep" (Cold Flow)

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. Because PTFE is soft and not cross-linked like rubber, it is highly susceptible to creep.

In a sealing application, this means an O-ring under constant compression will slowly flatten over time, losing its sealing force and eventually failing. This is the most significant mechanical limitation of a standard PTFE O-ring.

Low Wear Resistance

While its low friction reduces the rate of wear, pure PTFE is soft and has relatively low abrasion resistance. In high-speed or abrasive dynamic applications, a virgin PTFE seal can wear down more quickly than harder materials.

Mitigating Mechanical Weaknesses

These issues are well-understood and can be managed. Creep can be countered by using elastomer-energized seals, where a rubber O-ring sits inside a PTFE jacket, providing constant outward pressure. Wear resistance is improved by adding fillers.

Enhancing Performance with Filled PTFE

To overcome the mechanical limitations of virgin PTFE, various fillers can be blended into the material before it is sintered.

How Fillers Improve Performance

Fillers like glass fiber, carbon, graphite, or bronze act as a reinforcing matrix within the PTFE. They significantly improve key mechanical properties that are lacking in the pure material.

The Impact on Key Properties

Adding fillers dramatically increases mechanical strength, dimensional stability, and wear resistance. Most importantly, fillers are the primary method for reducing PTFE's tendency to creep under load.

The Trade-off of Using Fillers

This enhancement comes at a cost. Fillers typically reduce some of PTFE's exceptional chemical resistance and can alter its electrical insulating properties. The choice of filler must be matched carefully to the application's chemical environment.

Making the Right Choice for Your Application

Selecting the correct PTFE seal requires matching its unique profile to your primary goal.

- If your primary focus is dynamic sealing with low friction: Choose PTFE for its non-stick-slip behavior, but consider a filled grade for better wear resistance in high-cycle applications.

- If your primary focus is static sealing in an aggressive chemical or high-temperature environment: Virgin PTFE is an excellent choice, provided the compressive load is not high enough to cause significant creep.

- If your primary focus is high-pressure sealing or requires elastic memory: A standard PTFE O-ring is unsuitable; investigate elastomer-energized or spring-energized PTFE seals to provide the necessary resilience.

- If your primary focus is general toughness and high mechanical strength: PTFE is likely the wrong material, and you should evaluate other engineering plastics or high-performance elastomers.

Ultimately, you must view PTFE not as a direct replacement for a rubber O-ring, but as a problem-solving material for conditions where elastomers fail.

Summary Table:

| Property | Typical Value / Characteristic | Key Consideration |

|---|---|---|

| Coefficient of Friction | 0.05 - 0.10 | Extremely low, prevents stick-slip; ideal for dynamic seals. |

| Tensile Strength | 10 - 40 MPa | Low compared to other plastics; not suitable for high-stress applications. |

| Elongation at Break | 200 - 400% | Highly flexible and durable under deformation. |

| Hardness (Shore D) | 50 - 55 | Relatively soft; conforms well to surfaces but is susceptible to wear. |

| Young's Modulus | 0.3 - 0.8 GPa | Low stiffness; deforms easily under load. |

| Temperature Range | -73°C to 204°C (-100°F to 400°F) | Excellent thermal stability for extreme environments. |

| Creep (Cold Flow) | High Susceptibility | Will permanently deform under constant pressure; a major design limitation. |

Need a High-Performance PTFE Seal for Your Demanding Application?

PTFE O-rings are a specialized solution for extreme conditions where other materials fail. At KINTEK, we understand the critical balance between PTFE's exceptional chemical inertness and low friction and its mechanical limitations like creep.

We don't just supply standard parts; we provide engineered solutions. Whether you need:

- Virgin PTFE for ultimate chemical purity.

- Filled PTFE (with glass, carbon, or bronze) for enhanced strength, wear resistance, and reduced creep.

- Custom-Engineered Seals like elastomer-energized designs for high-pressure applications.

Our expertise in precision manufacturing and custom fabrication—from prototypes to high-volume orders—ensures you get a seal that is perfectly matched to the demands of your industry, whether it's semiconductor, medical, laboratory, or industrial.

Let's solve your toughest sealing challenge together. Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the difference between Teflon valves and PTFE lined valves? Choose the Right Valve for Your System

- What are the main components of a Teflon lip seal? A Guide to Reliable PTFE Sealing

- How are PTFE packings applied in the chemical industry? Ensure Leak-Free Sealing for Hazardous Fluids

- In which industries are PTFE coated fasteners commonly used? Essential for Corrosive & High-Performance Applications

- What considerations are important when selecting Teflon for CNC machining? Master Its Unique Challenges

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- How does carbon filler cause corrosion when combined with aluminum? Understanding Galvanic Corrosion Risks

- What are the advantages of PTFE/PFA lined ball valves? Superior Corrosion Resistance & Leak Prevention