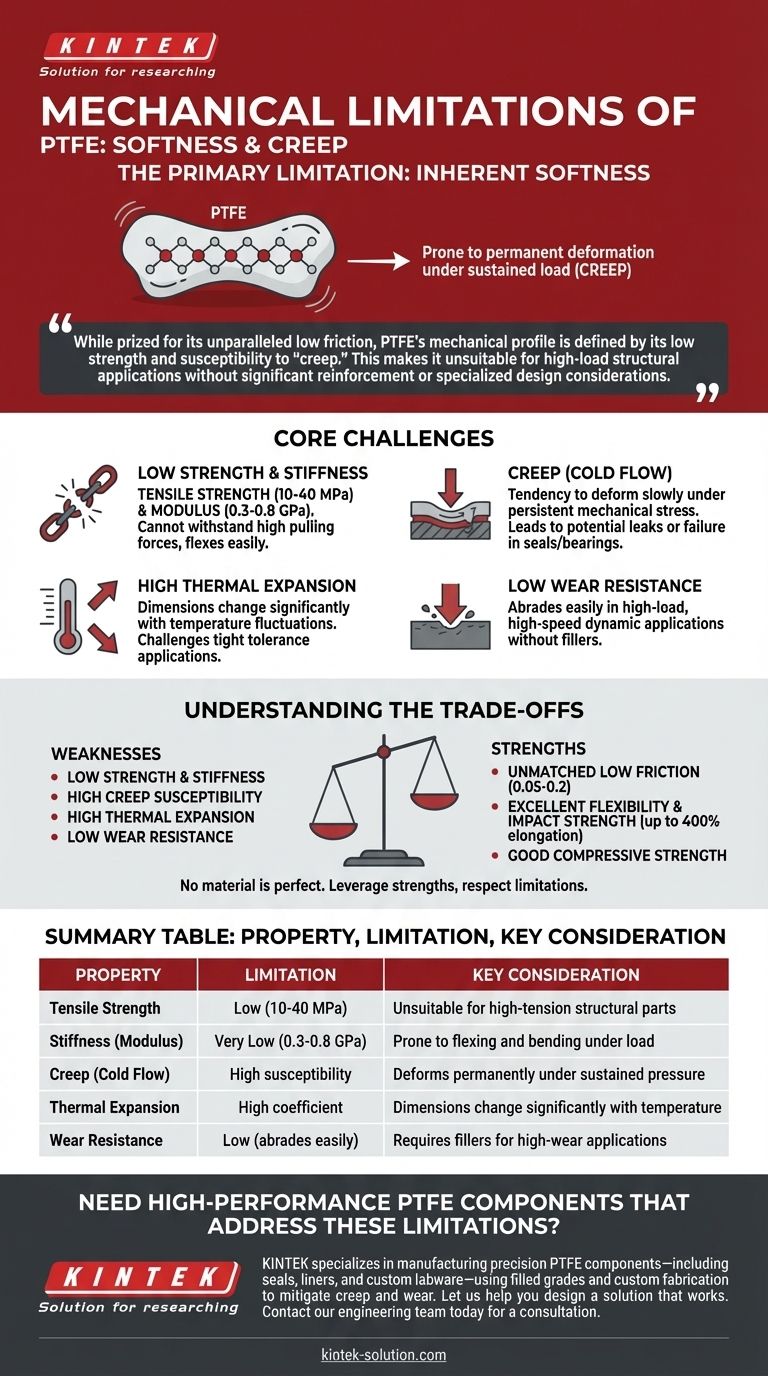

The primary mechanical limitation of PTFE is its inherent softness. Compared to other engineering plastics, Polytetrafluoroethylene (PTFE) has relatively low strength, stiffness, and hardness. This softness makes it prone to deforming permanently under sustained load, a phenomenon known as creep.

While prized for its unparalleled low friction, PTFE's mechanical profile is defined by its low strength and susceptibility to "creep." This makes it unsuitable for high-load structural applications without significant reinforcement or specialized design considerations.

The Core Challenge: A Soft and Pliable Material

The fundamental mechanical properties of PTFE dictate its best-use cases. Its softness is a double-edged sword, providing flexibility at the cost of strength and rigidity.

Low Strength and Stiffness

PTFE exhibits a low tensile strength (10-40 MPa) and a very low tensile modulus (0.3-0.8 GPa). This means it cannot withstand high pulling forces and will flex easily under load.

It is not designed for roles where it must bear significant structural weight or resist bending forces.

Low Hardness

With a Shore D hardness of 50-55, PTFE is a relatively soft material. This makes it susceptible to scratches and abrasion, though it contributes positively to its impact resistance.

The Critical Limitations: Creep and Dimensional Instability

For engineers designing mechanical components, the two most significant limitations to account for are creep and thermal expansion. These factors directly impact the long-term reliability and precision of a PTFE part.

The Problem of Creep (Cold Flow)

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress.

PTFE is particularly prone to this phenomenon. A component like a seal or a bearing under constant pressure will slowly change shape over time, potentially leading to leaks or failure.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion. Its dimensions will change significantly with fluctuations in temperature.

This makes it challenging to use in applications that require tight, consistent dimensional tolerances across a wide operating temperature range.

Low Wear Resistance

A common misconception is that PTFE's low friction equals high wear resistance. The opposite is true.

Despite its exceptional sliding properties, pure PTFE abrades easily. It is not ideal for high-load, high-speed dynamic applications without being enhanced with fillers like glass, carbon, or bronze.

Understanding the Trade-offs

No material is perfect. The key is to leverage PTFE's unique strengths while respecting its limitations. Its weaknesses in one area are often directly related to its advantages in another.

Unmatched Low-Friction Surface

PTFE's primary advantage is its incredibly low coefficient of friction (0.05-0.2).

Critically, its static and dynamic friction coefficients are nearly identical. This prevents "stick-slip" behavior, allowing for exceptionally smooth transitions from a resting state to motion.

Excellent Flexibility and Impact Strength

While not strong, PTFE is highly flexible and durable. It has a very high elongation at break (up to 400%), meaning it can stretch significantly before failing.

It also possesses good impact resistance, allowing it to absorb sudden shocks without fracturing like more brittle plastics.

Good Compressive Strength

In contrast to its poor tensile performance, PTFE handles compressive forces reasonably well. This property is crucial for its use in sealing applications, where it is squeezed to prevent leaks.

However, this must always be balanced against its tendency to creep under that same compressive load.

How to Apply This to Your Project

Choosing the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is low-friction sliding or a non-stick surface: PTFE is an excellent choice, but consider filled grades to improve wear resistance in dynamic systems.

- If your primary focus is a structural component under tension: PTFE is the wrong material. Look to high-strength polymers like PEEK, Nylon, or Acetal (Delrin).

- If your primary focus is a seal under constant compression: Pure PTFE may creep and fail over time. Use designs that account for this, or choose filled grades or seals with bonded rubber cores to maintain force.

- If your primary focus is a part requiring tight dimensional tolerances: PTFE's high thermal expansion makes it a challenging choice that requires careful design and analysis.

Ultimately, understanding PTFE's limitations is the key to correctly leveraging its unique low-friction properties in any design.

Summary Table:

| Property | Limitation | Key Consideration |

|---|---|---|

| Tensile Strength | Low (10-40 MPa) | Unsuitable for high-tension structural parts |

| Stiffness (Modulus) | Very Low (0.3-0.8 GPa) | Prone to flexing and bending under load |

| Creep (Cold Flow) | High susceptibility | Deforms permanently under sustained pressure |

| Thermal Expansion | High coefficient | Dimensions change significantly with temperature |

| Wear Resistance | Low (abrades easily) | Requires fillers for high-wear applications |

Need High-Performance PTFE Components That Address These Limitations?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand how to design for PTFE's unique properties, using filled grades and custom fabrication to mitigate creep and wear while maximizing its low-friction benefits.

Let us help you design a solution that works: Contact our engineering team today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE an ideal material for low-friction applications? Achieve Superior Performance with Self-Lubricating Components

- Why are PTFE products widely used across various industries? Discover the 4 Key Properties

- How is Teflon (PTFE) produced chemically? Unlocking the Secrets of High-Performance Polymer Manufacturing

- How is RPTFE different from standard PTFE in composition? A Guide to Enhanced Material Performance

- What are the properties and applications of virgin PTFE? Maximize Purity and Chemical Resistance

- In what medical devices is PTFE commonly used? Essential Components for Safety and Reliability

- What are the characteristics and applications of PTFE? A Guide to Its Extreme Performance

- What temperature range can Teflon withstand? From Cryogenic -328°F to High Heat 500°F