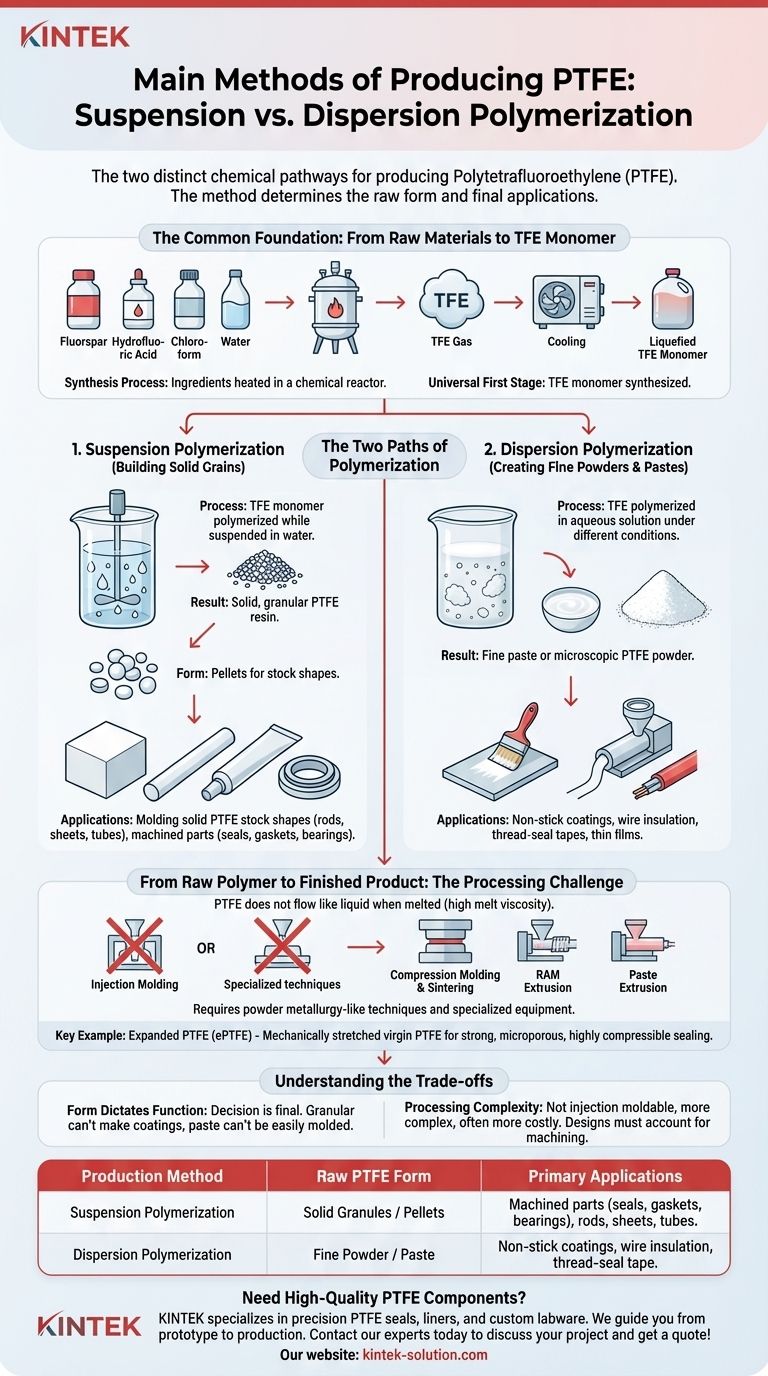

The two principal methods for producing Polytetrafluoroethylene (PTFE) are suspension polymerization and dispersion polymerization. These two distinct chemical pathways are not interchangeable; the method chosen at the outset determines the physical form of the raw PTFE and, consequently, its final applications, from solid machined parts to thin, non-stick coatings.

The core distinction lies in the final product's form. Suspension polymerization creates solid grains intended for molding physical components, while dispersion polymerization yields a fine paste or powder ideal for creating thin films and coatings.

The Foundation: From Raw Materials to Monomer

Before polymerization can occur, the essential chemical building block—tetrafluoroethylene (TFE) gas—must be synthesized. This is the universal first stage, regardless of the final PTFE type being produced.

The Raw Ingredients

The process begins with common industrial chemicals: fluorspar, hydrofluoric acid, chloroform, and water.

The Synthesis Process

These ingredients are heated within a chemical reactor to produce TFE gas. This gas is then cooled and liquefied, creating the pure monomer that will be linked together into long polymer chains to form PTFE.

The Two Paths of Polymerization

Once pure TFE is available, the production process diverges into one of two methods. The choice made here dictates the material's properties and how it can be processed.

Suspension Polymerization: Building Solid Grains

In this method, the TFE monomer is polymerized while suspended in water. This process results in the formation of solid, granular PTFE resin.

These grains can be further processed into larger pellets. This granular form is specifically designed for manufacturing solid PTFE stock shapes like rods, sheets, and tubes.

Dispersion Polymerization: Creating Fine Powders and Pastes

This method also polymerizes TFE in an aqueous solution but under different conditions, resulting in a milky, paste-like dispersion of microscopic PTFE particles.

This paste can be used directly for coatings or can be dried to produce a very fine, soft powder. This form is the basis for non-stick coatings, wire insulation, and thread-seal tapes.

From Raw Polymer to Finished Product

A critical characteristic of PTFE is that it does not flow like a liquid when it melts. This high melt viscosity means it cannot be processed using conventional techniques like injection molding.

The Challenge of PTFE Processing

Because it doesn't truly melt, raw PTFE must be fabricated using methods more akin to powder metallurgy. This requires specialized knowledge and equipment.

Common Fabrication Techniques

Granular PTFE from suspension polymerization is typically shaped using compression molding and sintering (heating under pressure below its melting point to fuse the particles) or RAM extrusion.

PTFE paste from dispersion polymerization is processed via paste extrusion. The resulting shapes are then machined into finished parts like seals, gaskets, bearings, and valve seats.

A Key Example: Expanded PTFE (ePTFE)

Specialty materials like ePTFE are created from 100% virgin PTFE resin. The material is mechanically stretched to create a strong, microporous fibrous structure, making it highly compressible and ideal for advanced sealing applications.

Understanding the Trade-offs

Choosing the right PTFE requires understanding the limitations imposed by its production and processing.

Form Dictates Function

The decision between suspension and dispersion polymerization is final. You cannot use granular, molding-grade PTFE to create a coating, nor can you easily mold a solid block from fine powder meant for paste extrusion. The application must be matched to the correct raw material form.

Processing Complexity

The inability to use injection molding makes PTFE fabrication more complex and often more costly than for other thermoplastics. Designs must account for the need for molding and subsequent machining, which can limit geometric complexity and increase waste material.

Making the Right Choice for Your Application

Your end goal determines which type of PTFE production process is relevant to your needs.

- If your primary focus is creating solid, structural components: You require granular PTFE produced via suspension polymerization, which will then be molded into a stock shape and machined.

- If your primary focus is applying a non-stick or protective coating: You need PTFE paste or fine powder originating from dispersion polymerization.

- If your primary focus is high-performance sealing in demanding environments: You should consider specialized, post-processed forms like expanded PTFE (ePTFE) for its unique compressible structure.

Understanding the fundamental production path is the first step to correctly specifying PTFE for any engineering challenge.

Summary Table:

| Production Method | Raw PTFE Form | Primary Applications |

|---|---|---|

| Suspension Polymerization | Solid Granules / Pellets | Machined parts (seals, gaskets, bearings), rods, sheets, tubes. |

| Dispersion Polymerization | Fine Powder / Paste | Non-stick coatings, wire insulation, thread-seal tape. |

Need High-Quality PTFE Components for Your Project?

Choosing the right PTFE form is critical for performance. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We leverage deep material expertise to guide you from prototype to high-volume production, ensuring your parts meet exact specifications. Let us help you select the optimal PTFE and fabrication technique for your needs.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs