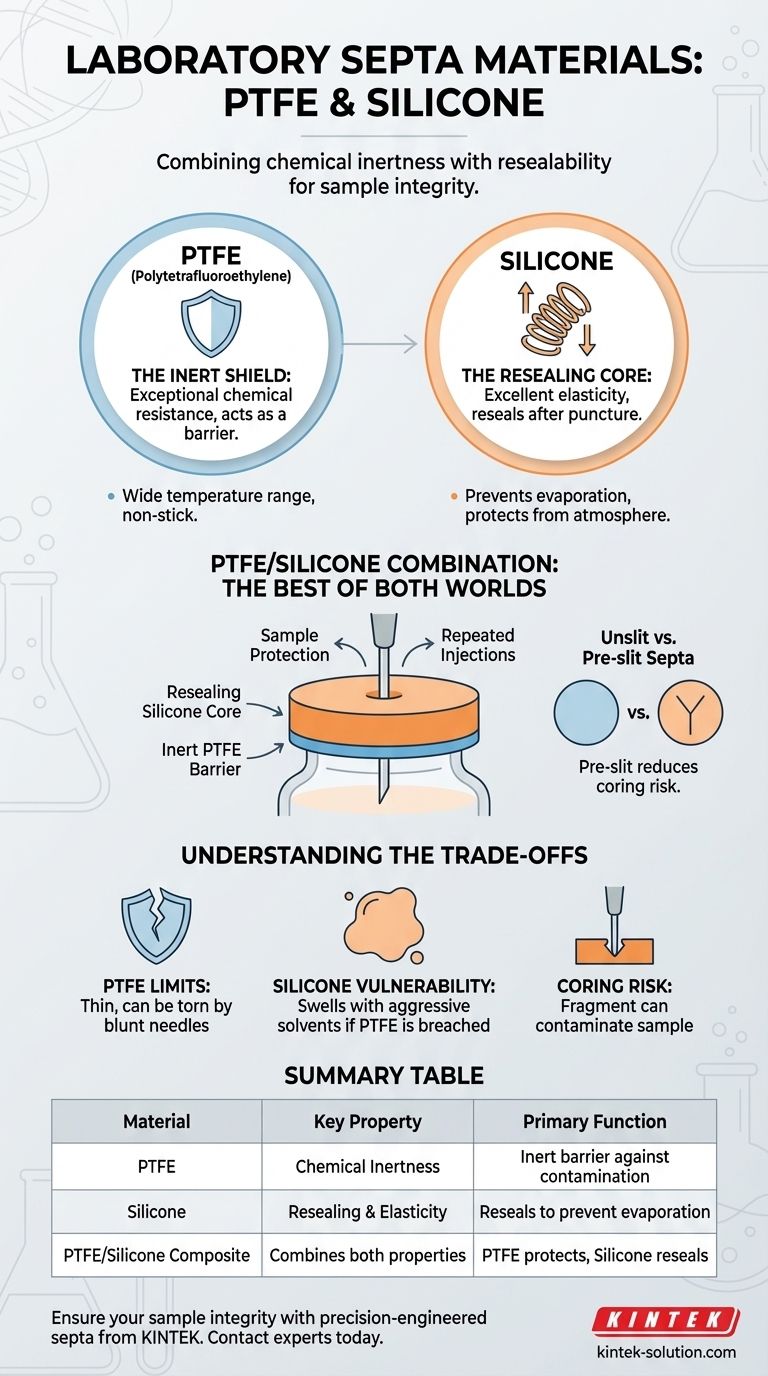

In laboratory settings, the two primary materials used for septa are Polytetrafluoroethylene (PTFE) and silicone. These materials are chosen for their distinct properties and are frequently used in combination to create a highly effective seal for applications like chromatography and sample storage.

The core principle is not choosing one material over the other, but understanding how their unique strengths—PTFE's chemical inertness and silicone's resealability—are combined to protect sample integrity against contamination and evaporation.

The Two Primary Materials: An Overview

To understand why septa are so effective, we must first look at the individual properties of the materials they are made from. Each serves a specific and critical function.

Polytetrafluoroethylene (PTFE): The Inert Shield

PTFE is a fluoropolymer, widely known by the brand name Teflon. Its primary characteristic is its exceptional chemical inertness.

This means it will not react with or leach into the vast majority of solvents, acids, and bases used in a lab. It acts as a perfect barrier, ensuring your sample remains pure.

PTFE is also valued for its non-stick properties and ability to withstand a wide range of temperatures.

Silicone: The Resealing Core

Silicone is a highly flexible and elastic synthetic rubber. Its most important property for a septum is its excellent resealability.

When a needle pierces a silicone septum, the material's elasticity allows it to close back tightly around the needle and reseal the hole almost completely upon withdrawal. This prevents solvent evaporation and protects the sample from the atmosphere.

How These Materials Work Together: The PTFE/Silicone Combination

In most high-performance applications, especially chromatography (GC/HPLC), you won't find septa made of just one material. Instead, they are a composite, or laminate, of both.

The Best of Both Worlds

A typical high-quality septum has a thin layer of PTFE laminated onto a thicker layer of silicone.

This design provides the ultimate solution: the chemically inert PTFE side faces the sample, providing a protective barrier, while the thick silicone layer provides the physical resealing capability needed for repeated injections.

Understanding Slit vs. Unslit Septa

PTFE/Silicone septa often come either solid or "pre-slit." A pre-slit septum has a small cut (like a "Y" or a cross) in the center.

This slit helps guide the needle through the tough PTFE layer, reducing the force needed for piercing and minimizing the chance of "coring," where the needle punches out a small piece of the septum material.

Understanding the Trade-offs

While the PTFE/Silicone combination is highly effective, it's crucial to be aware of its limitations and potential failure modes to ensure reliable results.

The Limits of PTFE

While extremely inert, the PTFE layer is very thin. Aggressive piercing with a blunt or incompatible needle can tear it, compromising the protective barrier.

The Vulnerability of Silicone

Silicone itself does not have the broad chemical resistance of PTFE. If the PTFE layer is breached, certain aggressive organic solvents (like chlorinated solvents) can cause the silicone to swell or degrade, leading to seal failure.

The Risk of Coring

Coring is a significant issue where a piece of the septum is pushed into the vial by the needle. This fragment can contaminate the sample or even block the autosampler needle, causing instrument downtime. Using pre-slit septa or correct needle types helps mitigate this risk.

Making the Right Choice for Your Application

Selecting the correct septum is critical for analytical accuracy. Your choice should be guided by the specific demands of your experiment.

- If your primary focus is maximum chemical compatibility: Always choose a PTFE/Silicone septum and ensure the PTFE side faces your sample.

- If your primary focus is repeated injections and resealability: Use a high-quality PTFE/Silicone septum. Consider a pre-slit version to reduce mechanical stress and prevent coring.

- If your primary focus is short-term, non-critical sample storage: A simple silicone or single-material septum might be adequate, but a PTFE-lined cap is always a safer choice for ensuring purity.

Ultimately, understanding how these materials function together empowers you to protect the integrity of every sample you handle.

Summary Table:

| Material | Key Property | Primary Function in a Septum |

|---|---|---|

| PTFE (Polytetrafluoroethylene) | Chemical Inertness | Acts as an inert barrier to protect the sample from contamination. |

| Silicone | Resealability & Elasticity | Allows the septum to reseal after needle puncture to prevent evaporation. |

| PTFE/Silicone Composite | Combines both properties | The PTFE layer faces the sample for protection; the silicone core provides resealing. |

Ensure your sample integrity with precision-engineered septa from KINTEK.

As a leading manufacturer of high-performance PTFE components for the semiconductor, medical, and laboratory industries, we understand the critical need for reliable seals. Our PTFE/silicone septa are designed to deliver the perfect balance of chemical inertness and resealability that your sensitive applications demand.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact specifications for your chromatography, sample storage, and other specialized needs.

Contact our experts today to discuss your specific requirements and request a quote. Protect every sample with KINTEK quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key properties of PTFE for sanitary gaskets? Ensuring Purity & Safety in Food & Pharma

- What types of PTFE liners are available for bottle caps? Choose Between Solid PTFE or Composite Liners

- What are the applications of PTFE-lined bottle caps? Ensure Ultimate Purity and Chemical Resistance

- What are the chemical compatibility differences between PTFE and silicone septa? Ensure Sample Integrity

- What makes PTFE-lined caps important? Ensure Sample Purity and Safety in Your Lab

- What makes Teflon membranes versatile for use in various laboratory environments? Unmatched Chemical & Thermal Stability

- What are the advantages of PTFE shovels over metal shovels? Precision Handling for Sensitive Materials

- Why is the combination of PTFE and silicone advantageous for chromatography septums? Achieve Unmatched Chemical Resistance and Durability