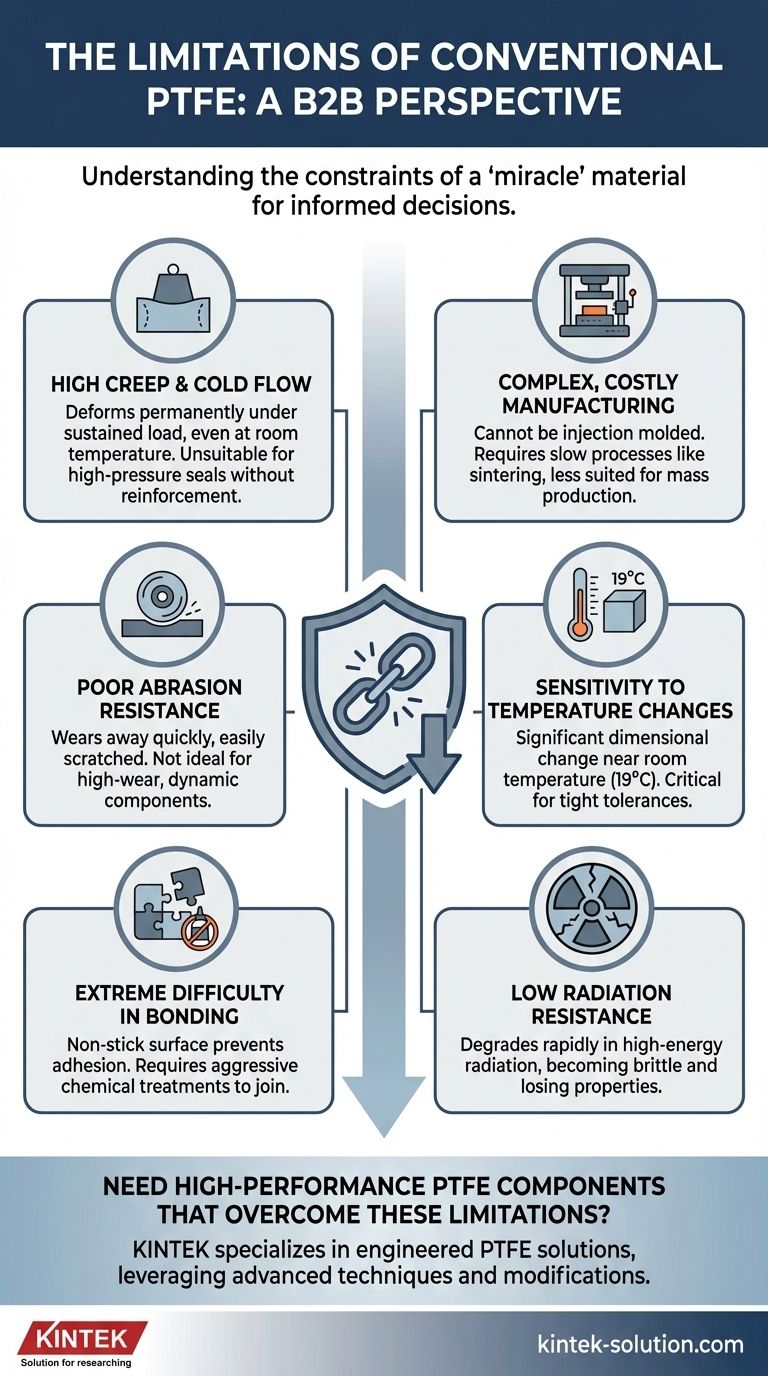

Despite its reputation as a "miracle" material, conventional Polytetrafluoroethylene (PTFE) possesses significant limitations that make it unsuitable for many applications. Its primary drawbacks are poor mechanical properties like a high tendency to creep and low abrasion resistance, an inability to be processed using standard high-volume techniques, and extreme difficulty in bonding or welding.

The very chemical stability that gives PTFE its incredible non-stick and corrosion-resistant properties is also the source of its greatest weaknesses: low mechanical strength and complex, expensive manufacturing requirements.

The Source of PTFE's Contradictions

The properties of PTFE are a direct result of its unique molecular structure, which is composed of a long chain of carbon atoms completely shielded by fluorine atoms.

The Power of the Carbon-Fluorine Bond

The bond between carbon and fluorine is exceptionally strong. This bond is what gives PTFE its renowned thermal stability and near-total chemical inertness.

It also creates a material with very low surface energy, which is why almost nothing sticks to it.

The Downside of Stability

This same chemical stability leads to an extremely high melt viscosity. Even when heated past its melting point of 327°C, PTFE does not flow like a typical thermoplastic.

This single characteristic is the root cause of its most significant manufacturing limitation: it cannot be processed using conventional methods like injection molding or extrusion.

Key Limitations in Practical Application

Understanding PTFE's theoretical weaknesses is one thing; seeing how they manifest in real-world applications is critical for material selection.

Manufacturing and Processing Challenges

Because it doesn't truly flow when molten, PTFE requires specialized and often slower processing methods.

Techniques like compression molding and sintering (compressing powder into a shape and then heating it) or ram extrusion are necessary. These processes are less suited for mass production and contribute to higher costs.

Poor Mechanical Properties

PTFE is a mechanically weak material, limiting its use in structural components.

Its most notable mechanical flaw is creep, also known as "cold flow." The material will deform permanently over time when subjected to a sustained load, even at room temperature. This makes it unsuitable for applications like high-pressure seals without reinforcement.

Furthermore, it has low abrasion resistance and can be easily scratched or worn away.

Sensitivity to Temperature Changes

PTFE undergoes a significant dimensional change near its glass transition temperature, which is around 19°C (66°F).

This phase change can affect the material's volume and is a critical design consideration for any application requiring tight tolerances that operates near room temperature.

Joining and Adhesion Issues

The famous non-stick surface that makes PTFE ideal for cookware also makes it nearly impossible to bond with adhesives or weld.

Joining PTFE components typically requires aggressive chemical surface treatments, such as sodium etching, to create a bondable surface. This adds complexity and cost to any assembly process.

Understanding the Trade-offs

Beyond its core mechanical and processing issues, several other factors can restrict the use of conventional PTFE.

Low Radiation Resistance

PTFE has very poor resistance to high-energy radiation, such as gamma rays.

Radiation exposure breaks down the polymer's molecular chains, causing the material to become brittle and lose its desirable properties rapidly.

Thermal Decomposition Risks

While PTFE is stable for continuous service up to 260°C (500°F), it will begin to decompose at very high temperatures.

Above 440°C, it can release toxic and corrosive fumes, which is a critical safety consideration in applications where extreme temperatures might occur.

Higher Material and Processing Cost

Compared to common polymers like polyethylene or polypropylene, PTFE is a premium material with a higher cost.

The complex manufacturing process required to form finished parts further increases the total cost of using PTFE in a product.

When to Avoid Conventional PTFE

To make the right decision, you must match the material's profile to your primary goal.

- If your primary focus is structural integrity: Avoid PTFE for any load-bearing application due to its low mechanical strength and high tendency to creep.

- If your primary focus is high-volume, low-cost production: Its inability to be injection molded makes it a poor choice for inexpensive, mass-produced parts.

- If your primary focus is abrasion resistance: Unfilled, conventional PTFE will wear down quickly and is not suitable for high-wear dynamic components.

- If your primary focus is operation in a radiation environment: PTFE degrades quickly and should not be used in applications with significant radiation exposure.

Choose PTFE for its unparalleled chemical resistance and low-friction surface, but always design around its inherent mechanical and manufacturing limitations.

Summary Table:

| Limitation | Impact on Application |

|---|---|

| High Creep / Cold Flow | Deforms under sustained load; unsuitable for high-pressure seals without reinforcement. |

| Poor Abrasion Resistance | Wears down quickly; not ideal for high-wear dynamic components. |

| Complex, Costly Manufacturing | Cannot be injection molded; requires slower processes like compression molding. |

| Extreme Difficulty in Bonding | Non-stick surface prevents adhesion; requires aggressive chemical treatments. |

| Sensitivity to Temperature Changes | Significant dimensional change near room temperature (19°C/66°F). |

| Low Radiation Resistance | Degrades rapidly in radiation environments, becoming brittle. |

Need High-Performance PTFE Components That Overcome These Limitations?

Conventional PTFE's weaknesses don't have to be a roadblock. KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) that are engineered to meet demanding application requirements. We leverage advanced techniques and material modifications to enhance performance where standard PTFE falls short.

We serve specialized industries where reliability is critical:

- Semiconductor

- Medical & Pharmaceutical

- Laboratory & Analytical

- Industrial Processing

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring you get a solution tailored to your specific needs.

Contact KINTEB today to discuss how our expertise in PTFE can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered chemically resistant? The Science Behind Its Unmatched Inertness

- What type of polymerization is used to create Teflon? A Guide to Free-Radical Chain-Growth

- What should be considered before specifying PTFE material for an application? Avoid Costly Design Failures

- How is Teflon used in industrial applications? Solve Extreme Heat, Chemical & Friction Challenges

- How does the composition of PTFE differ from other plastics? Unlocking Its Unique Chemical & Friction Properties

- Is PTFE considered a metal or plastic? Understanding Its True Classification

- What is PTFE and what are its primary applications? Unlock High-Performance Solutions

- Why is PTFE suitable for high-temperature applications? Unlock Reliable Performance Up to 600°F