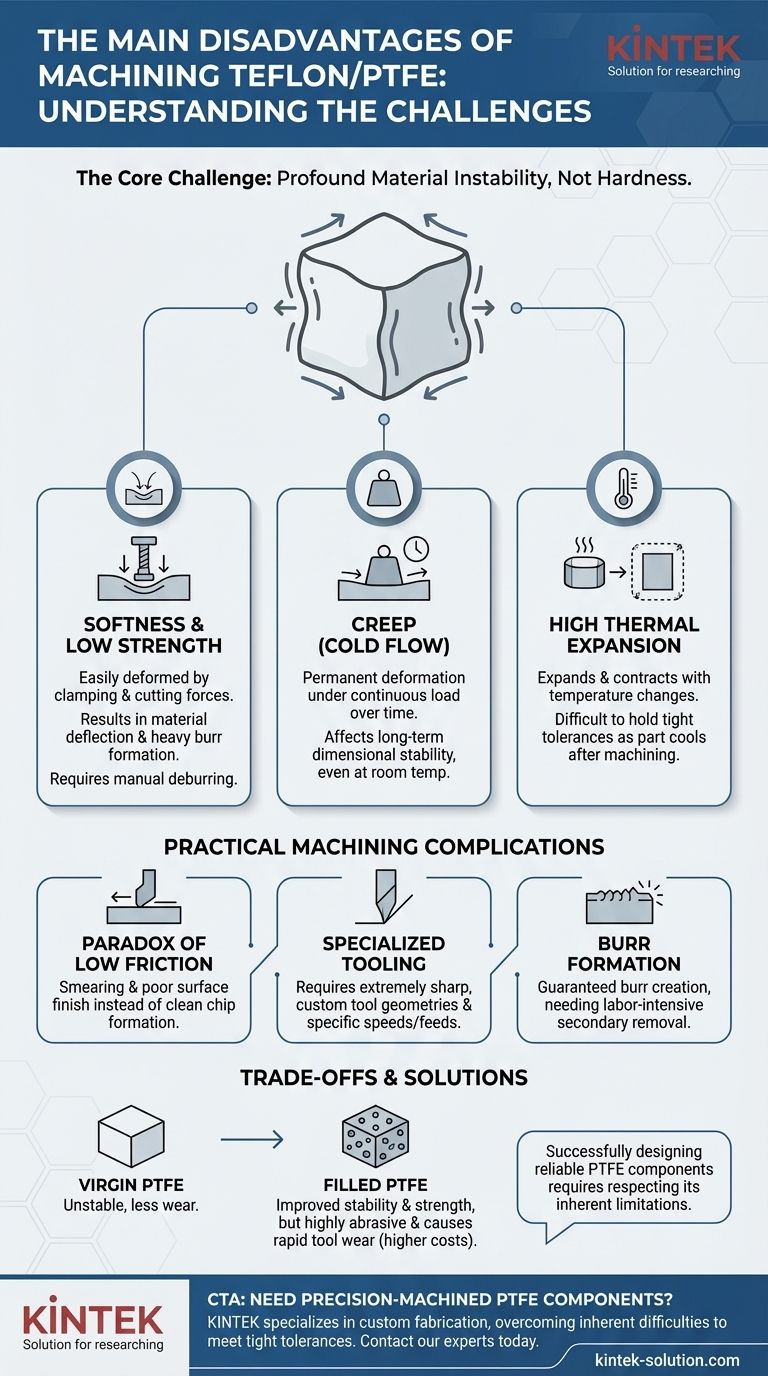

While prized for its unique properties, machining Teflon (PTFE) presents significant disadvantages that every engineer and machinist must understand. The core challenges stem directly from its inherent softness, its tendency to deform under pressure in a phenomenon known as "creep," and its high rate of thermal expansion. These factors combine to make achieving and holding tight tolerances exceptionally difficult.

The central problem with machining Teflon is not its hardness, but its profound lack of stability. The material’s tendency to move, deform, and expand under the slightest stress or temperature change is the fundamental challenge that dictates every aspect of the tooling, process, and design strategy.

The Core Challenge: Managing Material Instability

Successfully machining PTFE is less about removing material and more about controlling its inherent desire to change shape. The three primary material properties you must account for are its softness, its tendency to creep, and its thermal sensitivity.

Low Mechanical Strength and Softness

PTFE is an extremely soft material with low mechanical strength compared to metals or even other engineering plastics. This softness means it can easily be compressed or deformed by clamping pressure in a vise or fixture.

The cutting forces during machining can also cause the material to deflect away from the tool rather than shearing cleanly. This often results in the formation of heavy burrs, which require time-consuming manual deburring after machining is complete.

Creep (Cold Flow)

Teflon exhibits a behavior known as creep or cold flow. This means the material will slowly and permanently deform over time when subjected to a continuous load, even at room temperature.

This property has major implications for dimensional stability. A part that is perfectly in-spec immediately after machining may slowly deform out of tolerance if it is under any kind of constant pressure from a fastener or mating component in its final assembly.

High Thermal Expansion

PTFE has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with changes in temperature. The friction from the cutting tool can generate enough localized heat to make the part expand during the machining operation.

As the part cools back to ambient temperature, it will shrink, potentially pulling it out of the required tolerance. This makes active cooling and precise thermal management critical for any high-precision work.

Practical Machining Complications

The inherent instability of PTFE creates a series of direct, practical challenges on the shop floor that demand specialized approaches and tooling.

The Paradox of Low Friction

While Teflon's low coefficient of friction is its most famous benefit, it can be a liability during machining. Instead of creating a clean chip, the material’s slipperiness can cause it to stick or smear onto the cutting tool, leading to a poor surface finish and material buildup on the tool edge.

Specialized Tooling and Techniques

Standard machining tools and parameters are often ineffective. Machinists must use extremely sharp cutting tools with specific geometries, such as single-point tools for milling and parabolic flute drills, to get a clean shear.

Furthermore, a strategy of slow speeds and fast feeds is often required for turning operations. This minimizes heat buildup (addressing thermal expansion) while allowing the tool to cut the material before it has a chance to deform.

Burr Formation

The softness of PTFE almost guarantees that machining operations will create burrs—thin, raised edges of unwanted material. These must be carefully removed in a secondary operation, adding labor and cost to the final part. These sharp edges can negatively affect the performance or assembly of the component if not addressed.

Understanding the Trade-offs

Choosing to work with PTFE means accepting a series of compromises, from material selection to final cost.

Virgin vs. Filled PTFE

To combat the instability of virgin PTFE, fillers like glass, carbon, or bronze are often added. These filled grades offer significantly improved mechanical strength, dimensional stability, and resistance to creep.

However, this creates a new problem: abrasiveness. Filled PTFE grades are highly abrasive and cause rapid tool wear, requiring more frequent tool changes and potentially the use of specialized diamond-coated cutters, which increases tooling costs.

Cost and Complexity

Teflon is a relatively expensive raw material. When you add the need for specialized tooling, slower machining cycle times, and the potential for a higher scrap rate due to its difficulty, the total cost of a machined PTFE component is often much higher than that of a comparable part made from metal or a more stable plastic.

Bonding and Adhesion

It is critical to remember that PTFE is, by its nature, a non-stick material. This makes it extremely difficult to bond to other surfaces using conventional adhesives. This can be a significant design limitation if your application requires it to be glued or permanently attached to another component.

Making the Right Choice for Your Application

To decide if PTFE is the correct material, you must weigh its unique benefits against these significant manufacturing challenges. Your final application and design intent should be your guide.

- If your primary focus is extreme precision and long-term dimensional stability: Acknowledge that holding tolerances below +/- 0.002 inches is a task for an expert machinist and consider using a filled grade of PTFE or an alternative stable polymer like PEEK.

- If your primary focus is leveraging its chemical resistance and low friction: Design parts with generous tolerances, simple geometries, and features that are not sensitive to minor deformation to minimize the impact of its machining challenges.

- If your primary focus is cost-effectiveness for a non-critical component: Be aware that the specialized labor, slow cycle times, and potential for high scrap rates can make Teflon a more expensive choice than initially anticipated.

Ultimately, successfully designing and manufacturing reliable PTFE components begins with a deep respect for the material's inherent limitations.

Summary Table:

| Disadvantage | Key Challenge | Impact on Machining |

|---|---|---|

| Creep (Cold Flow) | Permanent deformation under load | Dimensional instability over time |

| High Thermal Expansion | Expands/contracts with heat | Difficult to hold tight tolerances |

| Low Mechanical Strength | Soft, easily deformed | Heavy burrs, poor surface finish |

| Abrasive Filled Grades | Rapid tool wear | Increased tooling costs and complexity |

Need Precision-Machined PTFE Components Despite the Challenges?

At KINTEK, we specialize in overcoming the inherent difficulties of machining Teflon/PTFE. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components meet the tightest tolerances, even with soft, unstable materials.

We serve the semiconductor, medical, laboratory, and industrial sectors with precision-manufactured PTFE seals, liners, and labware. Let us handle the complexities of tooling, thermal management, and burr-free finishing for you.

Contact our experts today to discuss your project and receive a quote tailored to your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection